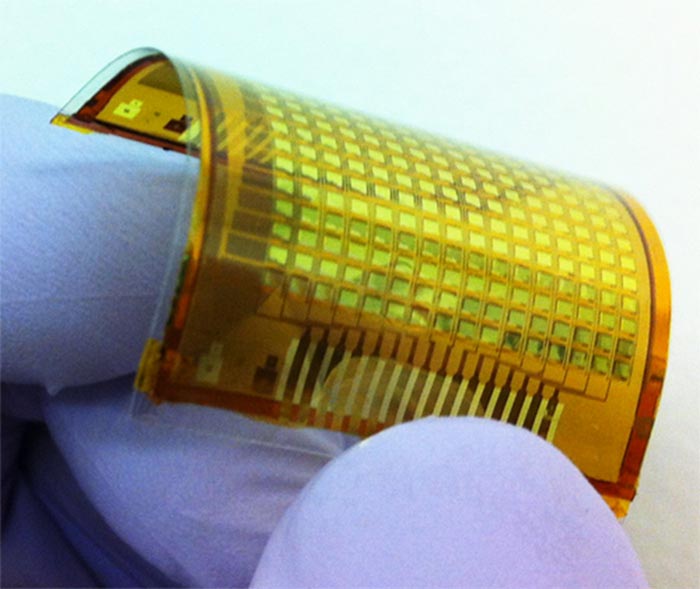

Researchers at the University of California at Berkeley have created touch-sensitive “electronic skin(e-skin)” through integrating three distinct electronic components including semiconducting carbon-nanotube transistors, pressure-sensitive polymer sensors and OLEDs. The three components are integrated over large areas on a single plastic substrate, to form a mechanically flexible sensor network that immediately light up when being touched. And the harder it is touched, the brighter the light.

Each pixel in the active matrix of the device contains a nanotube transistor with its drain electrode connected to the anode of an OLED. A pressure-sensitive polymer is laminated on top of the OLED and it is in electrical contact with the cathode of the OLED at each pixel. The top surface of the polymer is made conducting by coating it with silver ink and acts as the ground contact. When the device is touched, current flows through the polymer layer and switches the OLED on.

“Our e-skin is the first flexible system that responds to pressure stimuli of varying intensities and provides a real-time response by emitting light through the integrated OLED display,” team member Chuan Wang says. “In the system, OLEDs are turned on only where the surface is touched and the intensity of the emitted light depends on the amount of pressure applied. This basically allows us to visualize the applied pressure.”

The e-skin can be laminated on a variety of surfaces, curved or otherwise, he adds. Potential applications include robot skin, interactive wallpaper and interactive in-vehicle dashboards. “I can also imagine things like e-bandages applied to a person's arm that would continuously monitor blood pressure and pulse rates, for example, while providing real-time feedback.”

The Berkeley team is now busy integrating additional sensing capabilities—such as those that respond to thermal and light stimuli—into its e-skin system. “We are also experimenting with the possibility of having the whole system built using roll-to-roll printing processes for large-scale, low-cost fabrication of the sensor networks.” reveals Wang.