Horticulture lighting applications have become a critical market for the LED industry. LED lighting enables researchers and growers to break the limitation of conventional farming regarding the weather and space. With the help of LED lighting, innovative horticultural researches and activities were reported from all around the world. Various cultivation methods were developed to grow crops in places that we would not consider possible in the past.

With the end of the year approaching, let’s look back at how scientists and industry innovators have used LED lighting to practice horticulture in “impossible” locations.

Underground coal mines for vertical farms

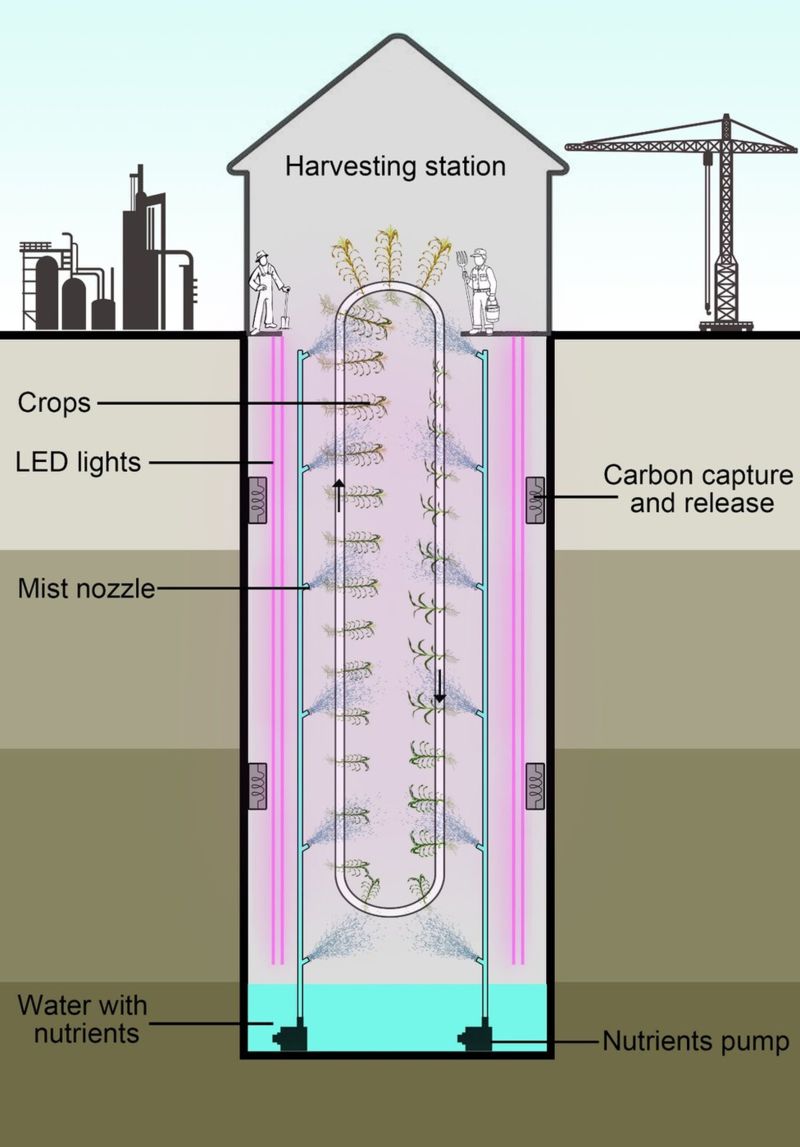

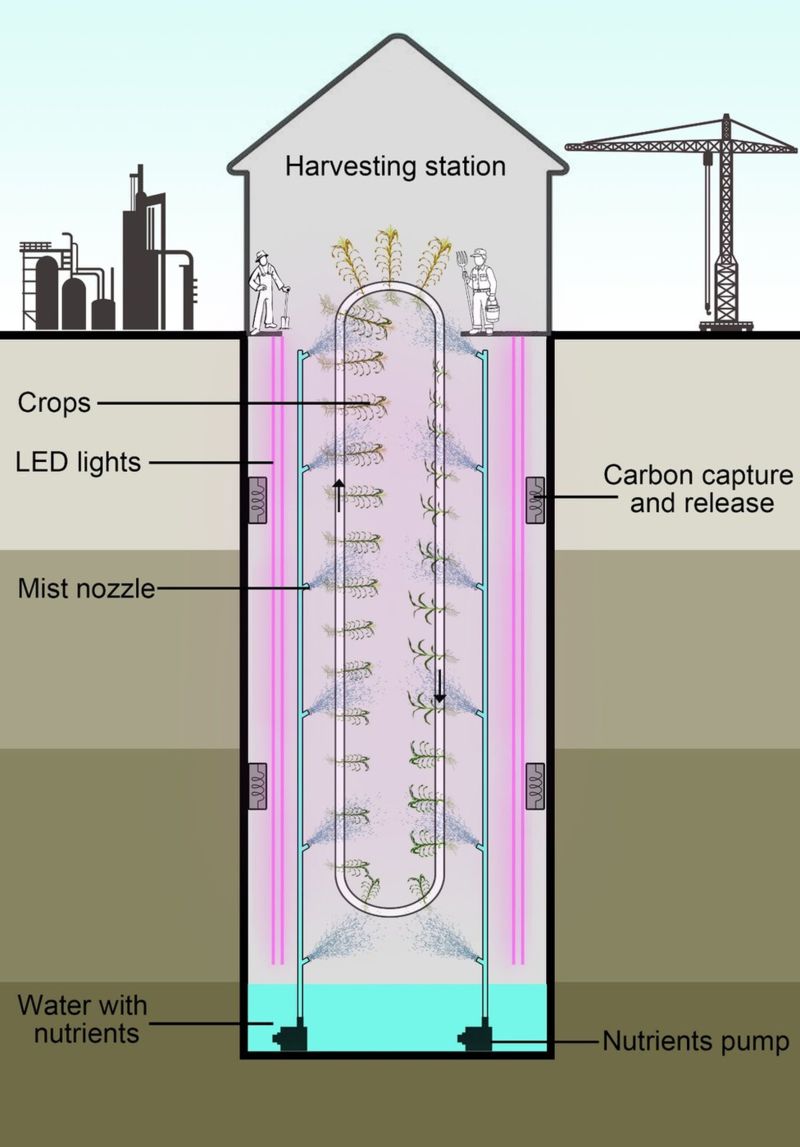

Researchers at the University of Nottingham has proposed to transform abandoned coal mines into vertical farms as these underground spaces are barely affected by the weather and seasons and could be directly used in the hydroponic systems, reported BBC.

(Image: University of Nottingham)

As there are many old mines that are not in use anymore, regenerating these places and turning them into indoor horticulture facilities would be an economical option instead of building more giant greenhouses. Furthermore, subterranean farms could use CO2 capture and release systems, as these spaces are well suited to carbon storage. Additional carbon can also be adsorbed in materials in the subterranean space to reduce CO2 concentration in the environment.

Vertical farm in an old tunnel in South Korea

NextOn, a Korean indoor farming company, has transformed a closed old tunnel into a vertical farm adopting LED lighting technology. The hydroponic indoor vertical farm was set up in an old tunnel in Okchean, South Korea, and was said to be the world’s first farm in a tunnel.

According to the project leader, the tunnel provides a suitable growing condition for crops as the temperature inside remains stable all year round. The farm has been supplying fresh produces to local food retailers since August 2018.

Emirates Airline sets up vertical farm in desert

Emirates Airline has announced that it is building the largest vertical farm next to Dubai’s Al Maktoum International Airport for supplying fresh food for airlines and restaurants in the airport.

Emirates’ subsidiary, Emirates Flight Catering (EKFC), set up a joint venture with farming startup Crop One for the 12,000 square meter indoor vertical farm project. As the construction has begun since November 2018, the first crop is expected to be served for passengers by the end of 2019.

Food Grows in Shipping Containers

Freight Farm is a U.S.-based company that developed Leafy Green Machine, a hydroponic farming system in a shipping container. The shipping container is equipped with a seedling area and 265 vertical crop columns with LED lighting. An automation system is adopted to monitor the growing environment.

(Image: Freight Farms)

With the controlled growing condition all regulated in the shipping container, individuals and organizations can start their farming project anytime anywhere. Its clients include Google, small farming businesses in the U.S. and Europe, and several universities. In October, Alabama Power has also established its growing project with Leafy Green Machine of Freight Farm.

Osram helps NASA for food production in the space

With the purpose of supplying fresh food for the astronauts off the earth, NASA has been working with Osram to research efficient approaches to produce vegetables during space travel.

Osram has provided its research LED lighting system for NASA. The horticulture lighting system allows researchers to easily adjust lighting conditions to optimize plant growth in various conditions and then replicate those settings in the Advanced Plant Habitat on the International Space Station.

(Image: Osram/NASA)

Food supply has become a global issue as the world population is still booming and agriculture labor and lands continue to decrease. High-tech indoor farming adopting LED technology and hydroponic system is believed to be an efficient solution to solve the problem.