Last week at Micro LEDforum 2018, experts from the industry have shared their advanced Micro LED technologies and illustrated the possibilities of further development of Micro LED. As mass transfer is the most difficult task to tackle, many speakers have introduced their unique method to solve the issue. Uniqarta, a U.S. based start-up was invited by LEDinside to present its Laser Enabled Advanced Placement (LEAP) technology at Micro LEDforum 2018.

Ronn Kliger, the CEO and co-founder of Uniqarta, talked about how its solution of using laser to transfer LED die can significantly accelerate the transfer process. Since a Micro LED die is smaller than 100 micrometers, and there might be millions of Micro LEDs on one display, using the conventional pick-and-place method which processes 10-25 thousand dies per hour is simply inadequate for Micro LED display manufacturing. Thus, Uniqarta has developed the Laser Enabled Advanced Placement method to not only speed up the process but also be selective when placing the Micro LED dies.

(Ronn Kliger, CEO and co-founder, Uniqarta)

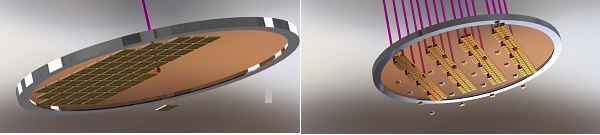

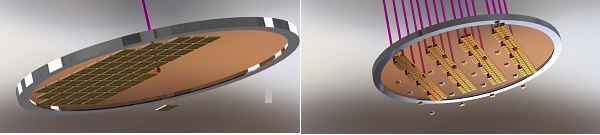

Kliger demonstrated a short video clip to show how fast the transfer could be with LEAP technology. 336 Micro LED dies were transferred in 86 millisecond (msec) with 84 laser pulses and each of the pulses transferred 4 dies. The die size was 130μm*160μm. It means the method can achieve a transfer rate of 14 million dies per hour, which dramatically improves the transfer efficiency compared to the pick-and-place method.

(Image: Uniqarta)

According to Uniqarta, LEAP is different from previous laser transfer approach with its blistering transfer which protects die from laser and leads to minimal placement errors. Furthermore, via single- and multi- die placement modes, LEAP technology can remove bad dies and replace them with good ones. “It is not only fast, but also precise,” Kliger noted.

This disruptive technology of Uniqarta, which offers an exceptional transfer rate and achievement, will help to advance Micro LED manufacturing process. The enhanced transfer method will be the key for scaling down the cost of Micro LED production.

To collect and share more insights of Micro LED technologies, LEDinside is currently hosting the 2018 Micro LED Technology Research Contest and would like to invite companies, academic institutions and other corporate entities to submit abstracts or outlines of their latest technical papers related to innovative Micro LED technologies. For more details, please visit: LEDinside " Micro LED Technology Competition" Calls for Paper Abstracts.