Researchers found a new method of photonic cooling by running LED with electrodes reversed. Researchers believe that this approach could improve cooling technology for future microprocessors, which will include various transistors in a small space that current methods cannot remove heat quickly enough. The finding was published on Nature on February 13 by a research team at the University of Michigan.

Linxiao Zhu, the lead author on the research article, explained, “Usually for thermal radiation, the intensity only depends on temperature, but we actually have an additional knob to control this radiation, which makes the cooling we investigate possible.” That knob is electrical. In theory, reversing the positive and negative electrical connections on an infrared LED will not just stop it from emitting light, but will actually suppress the thermal radiation that it should be producing because it is at room temperature.

However, measuring this cooling is complicated because to get enough infrared light to flow from an object into the LED, the two would have to be extremely close together—less than a single wavelength of infrared light. This is necessary to take advantage of “near field” or “evanescent coupling” effects, which enable more infrared photons, or particles of light, to cross from the object to be cooled into the LED. At this close proximity, a photon that would not have escaped the object to be cooled can pass into the LED.

The group proved the principle by building a minuscule calorimeter, which is a device that measures changes in energy, and putting it next to a tiny LED about the size of a grain of rice. These two were constantly emitting and receiving thermal photons from each other and elsewhere in their environments.

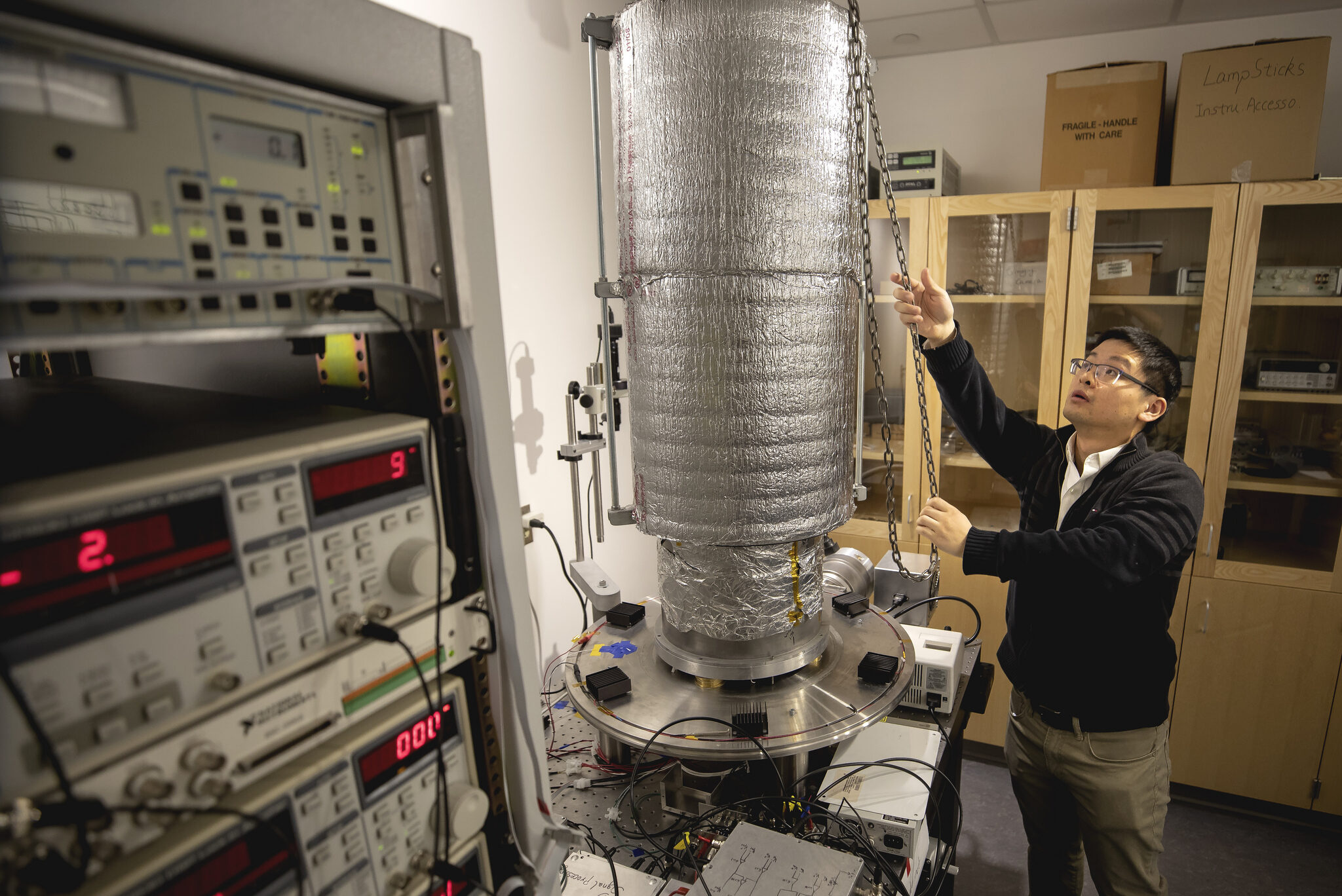

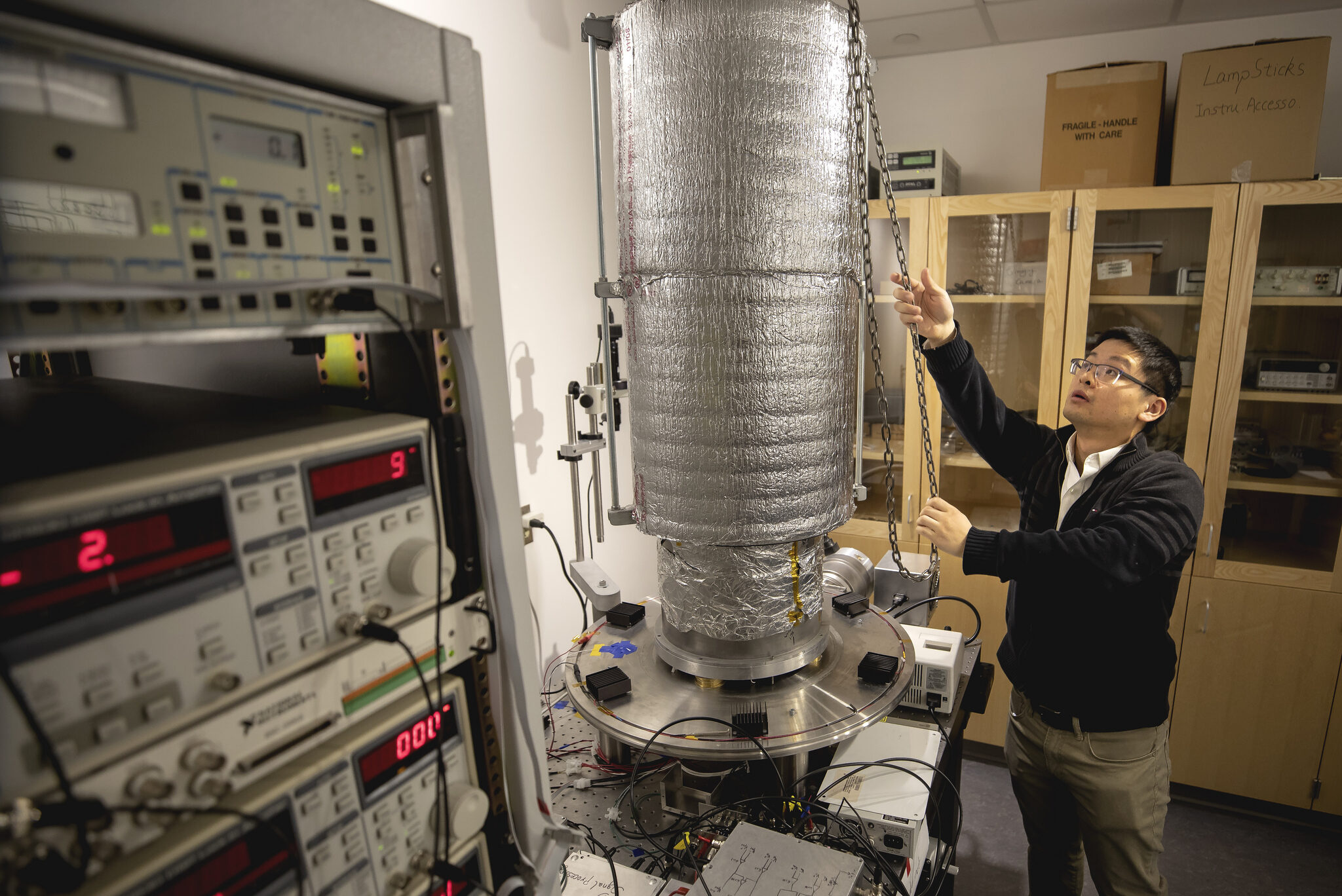

(Linxiao Zhu shows the experimental platform that housed the calorimeter and photodiode. This system can damp vibrations from the room and building, steadily holding the two nanoscale objects 55 nanometers apart. Image: Joseph Xu/University of Michigan)

Once the LED is reverse biased, it began acting as a very low temperature object, absorbing photons from the calorimeter. At the same time, the gap prevents heat from traveling back into the calorimeter via conduction, resulting in a cooling effect.

The team demonstrated cooling of 6 watts per meter squared. Theoretically, this effect could produce cooling equivalent to 1,000 watts per meter squared, or about the power of sunshine on Earth’s surface.

The result might serve as a new cooing technology for future smartphones and other computers which process more computing in smaller devices so that fast heat dissipation become critical. With improvements of the efficiency and cooling rates of this new approach, the team envisions this phenomenon as a way to quickly draw heat away from microprocessors in devices.