Micro LED as the innovative display technology is expected to replace TFT-LCD and OLED display in the near future with its high performance including high resolution, high contrast, self-emission, low power consumption and long life.

However, the technology still encounter several bottlenecks. The most challenging one for researchers and manufacturers is the notorious mass transfer process which requires bonding RGB LED chips to display backplane accurately and efficiently. The task also needs to tackle the issues caused by different chip materials such as breakable red Micro LED. Until now, barely any proposed mass transfer technology has made it way to mass production phase.

Dr. Kuo Hao-Chung at Taiwan’s National Chiao Tung University in collaboration with Saphlux from the U.S., and researchers at Yale University and Xiamen University have achieved the production of full color Micro LED display with high color stability using semipolar InGaN LED and quantum dot photoresist. Their results will be published soon on Photonics Research.

Dr. Kuo addressed that the team continues to focus on color conversion based on quantum dot technology which requires only blue or UV LEDs as a light source and quantum dots in different color to achieve full color display. The method not only simply the mass transfer process but also deliver good performance in color rendering.

(Image: Chen et al. 2020)

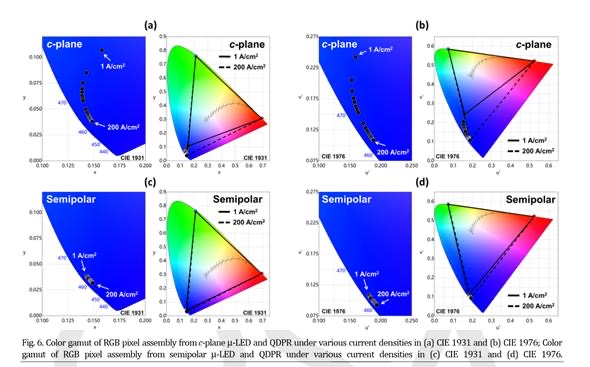

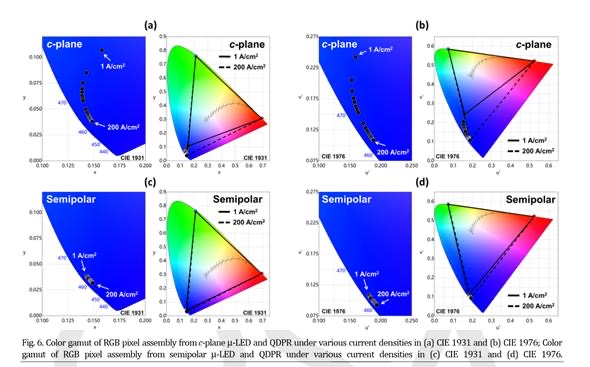

Apart from the difficulties in mass transfer process, many obstacles also occur in LED chips. Blue and green colored LED chips usually change color as the operating current alters. So if the brightness of display needs to be adjusted to fit into the environment, the colors presented by the display may shift, which is adverse to display applications. Thus, overcoming the color shifting problems of Micro LED chips is critical.

The team used semipolar wafer to produce Micro LED chips to stabilize emission wavelength and tackled the issue of wavelength shift and color shift. In the research, quantum dot photoresist was adopted to manufacture color pixels. The approach can largely reduce the difficulty of mass transfer process as it does not need to transfer RGB chips separately.

Based on the methods, the team successfully achieved a full color Micro LED array with high color stability which can be applied to patterning large-area device, pushing the development of Micro LED display technology.