Igniting Digital Transformation through Organizational and Cultural Changes: AUO University Cultivating Internal Cross-Domain Experts, Driving the AUO Transformational Strides

AUO today announced that it has received the Manufacturing Leadership Awards (MLA) by the National Association of Manufacturers (NAM) for the second time. With its advanced digital technology and smart solutions, AUO has maintained stable manufacturing production and smart management during a period of global transformation throughout the industry, and has been recognized in the “Digital Supply Chains” category. Additionally, in response to the rapid changes in the technology industry, AUO University has integrated diverse learning resources to offer courses on AI, research and development innovation, and sustainable development. This supports employees in their continuous education and interdisciplinary learning, enabling them to stay updated with the latest global industry trends. AUO’s dedication to cultivating core talents for its biaxial transformation has also earned recognition from the MLA in the "Transformational Business Cultures" category. In addition, AUO has stood out among many companies and has been awarded the “Manufacturing in 2030 Award” by the Manufacturing Leadership Council, recognizing AUO's pioneering role in guiding the manufacturing industry towards a smart and sustainable future.

“AUO has been promoting smart manufacturing since 2015. We not only focus on the implementation of software and hardware but have also established AI courses at AUO University. This initiative aims to guide professionals in continuous learning and mindset transformation. To date, AUO has cultivated over 1,300 internal experts.” Said Dr. Frank Ko, CEO and President of AUO. “Through the introduction of automated equipment and integration of Internet of Things (IoT) and Industrial IoT (IIoT), we’ve upgraded our production processes to become more intelligent. This allowed us to achieve remote monitoring and management and integrate AI deep learning capabilities. By leveraging big data, we’re able to achieve self-prediction and decision-making, successfully advancing towards fully automated production processes. As a result, we achieved efficient production and stable quality, positioning ourselves as a reliable supply chain partner for global customers.”

"As the only company from Taiwan selected this year, AUO stood out in the domains of 'Digital Supply Chains' and 'Transformational Business Cultures'. With its success attributed to a clear digital transformation strategy and a long-term talent cultivation," said David Brousell, Founder of the Manufacturing Leadership Council. "AUO is not only recognized for its continued leadership in driving transformation within the manufacturing industry but also commended for AUO University's provision of diverse learning resources to employees, ensuring a sustainable and innovative momentum. The achievements of AUO in digital transformation and its exemplary model of cultivating diverse talents serve as valuable lessons for other companies, deserving high recognition."

Implementing Smart Upgrades throughout Full Manufacturing Processes to Create Efficient Digital Supply Chains

Looking back over the past three years, the global community has faced unprecedented macroeconomic challenges such as the pandemic, geopolitical instability, global inflationary pressure, and interest rate hikes, which resulted in significant impacts worldwide, which further posed severe trials for the industry supply chains. As a leading global provider of display solutions, AUO has been dedicated to the long-term digital transformation and upgrade of its factories. Through smart research and development, optimized supply chain management, digital manufacturing, and warehouse logistics, AUO has comprehensively optimized its product manufacturing process. This has resulted in a significant improvement in production efficiency and information flow. In 2021, AUO Longtan Plant achieved a record-high yield rate and also achieved full on-time deliveries without delays throughout the whole year.

In the smart research and development aspect, AUO developed a color saturation simulation system and integrated big data analysis algorithms. This system enables simulations related to material selection to be made and predicts customer preferences for color and material transparency in advance. As a result, the efficiency of the design phase has improved by 83%. Moreover, AUO established standardized component databases for front end panel production with layout design algorithms. This successful integration has resulted a 50% time reduction during photomask design.

In terms of supply chain optimization, AUO achieved complete product lifecycle management through the seamless integration of business orders, procurement management, and suppliers. By achieving material cost transparency, AUO oversees the overall cost during product designing phase. With the assistance of smart pricing estimation system, AUO assists customers by reducing price estimation time by 85%. Additionally, by leveraging resource optimization models, AUO can endeavor to fulfill orders and provide stable and reliable supply chain support for its customers.

AUO applies robotic arms combined with AI visualization technology to automate the packaging process, enhancing production and shipping efficiency on the assembly line.

AUO recognized with Manufacturing Leadership Awards for painless upgrade to sustainable smart factory through AI for old factories.

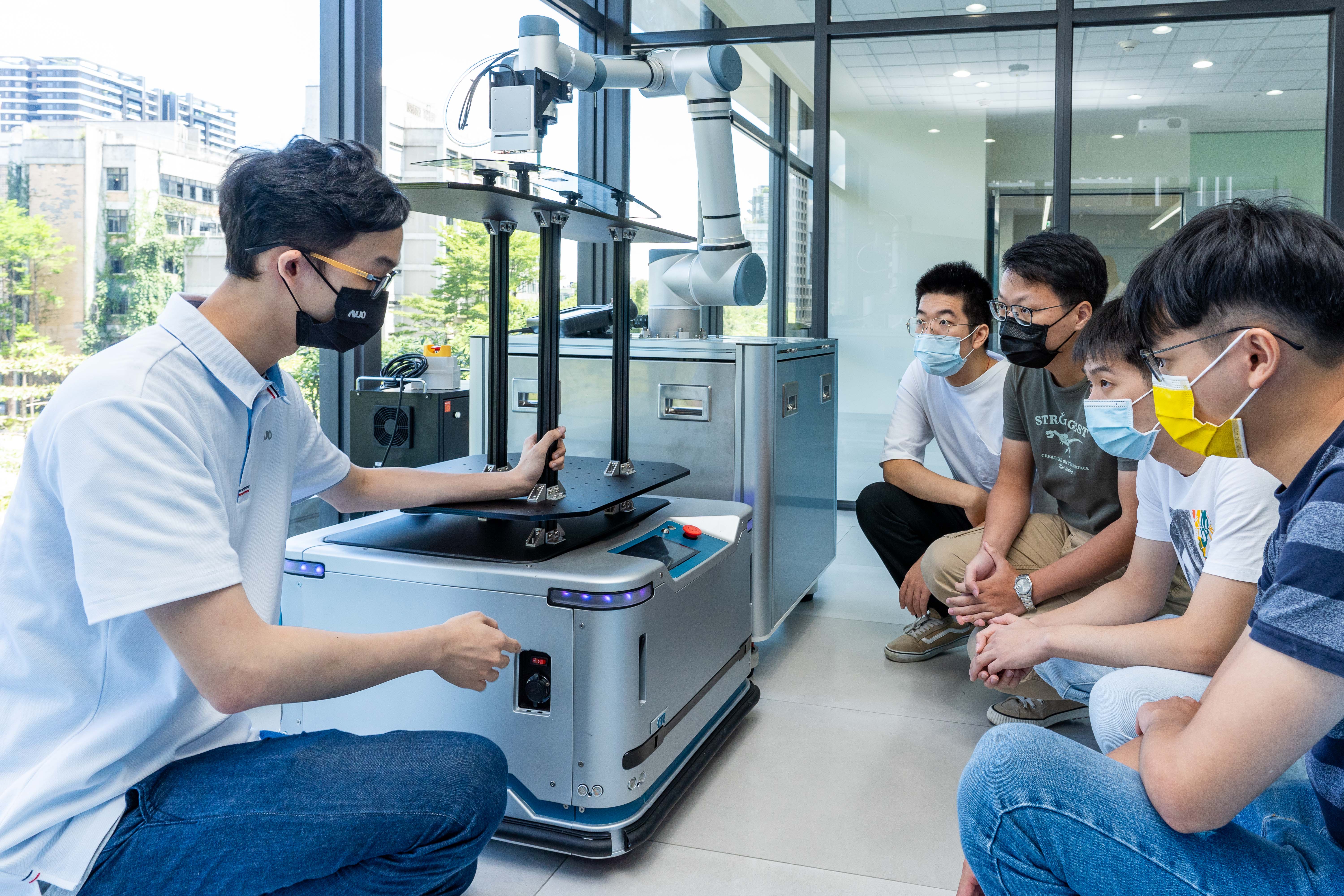

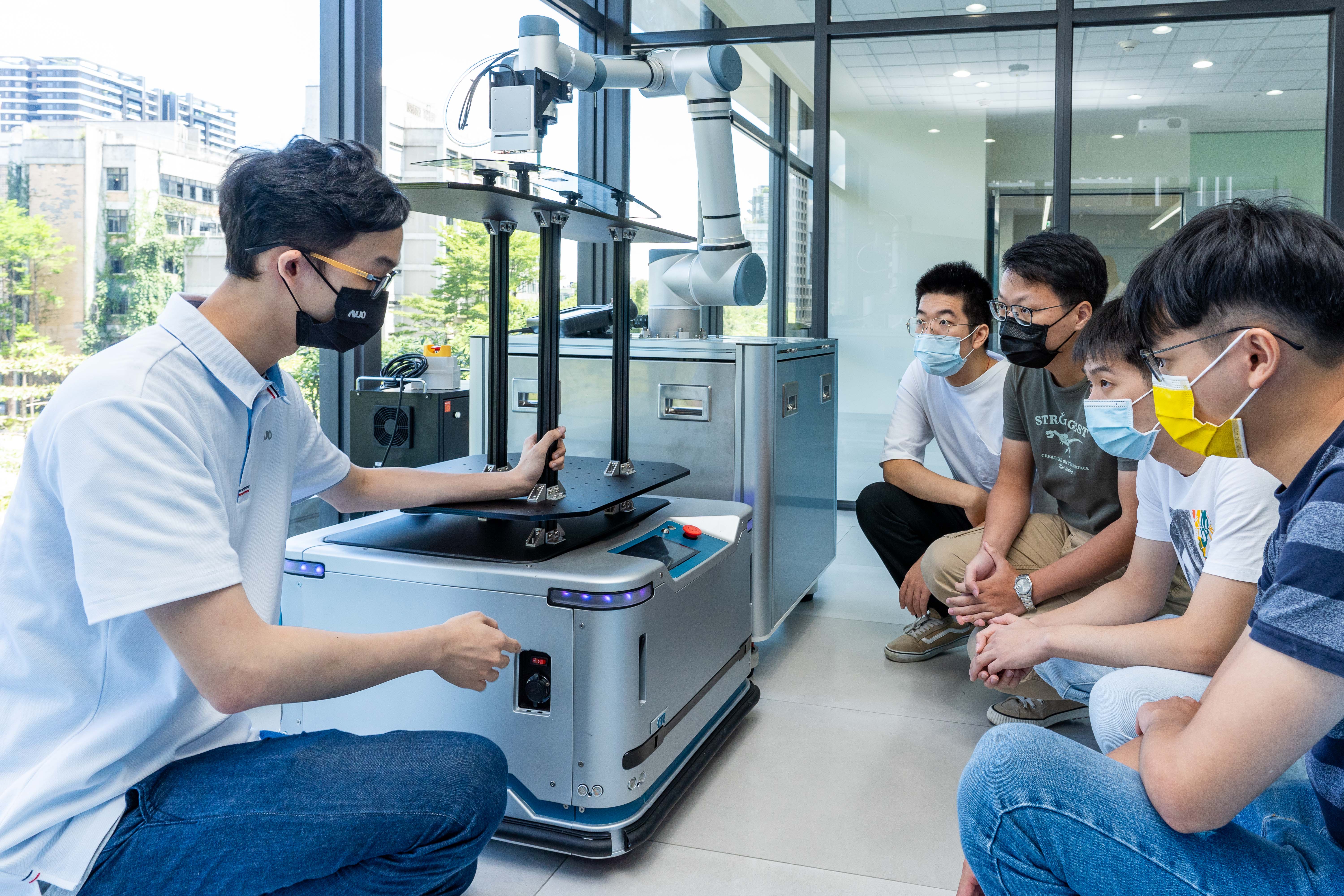

AUO actively promotes industry-academia collaboration, providing practical application fields for academia, collaborating to explore core issues, and jointly discovering solutions to drive developments in smart manufacturing technologies.

AUO recognized with the MLA again for its advanced digital transformation strategy and achievements.

In the digital manufacturing phase, AUO has undergone comprehensive smart upgrades in production scheduling, equipment maintenance, process quality, and defect detection. To overcome capacity limitations and the complexity of scheduling, AUO utilizes a data-driven smart scheduling system. This system enhances the proactivity and adaptability of production scheduling. In addition, AUO utilizes smart interconnected devices such as SPIIDER, AI-based Prognostics and Health Management (PHM) platform, and mixed reality (MR) technology for remote equipment maintenance. These technologies have resulted in a 10% increase in equipment utilization rate, 20% reduction in unplanned downtime, and the implementation of bionic collaborative robots to assist with equipment maintenance. This has enabled standardized operations and significantly reduced human-related risks. AUO boasts rigorous quality control in its processes, and accordingly utilizes automated machine learning (AutoML) to identify key factors that affect yield rates at an early stage. AUO also implements intelligent inspection and repair systems for fully automated defect recognition, localization, and repair. This approach resolves issues related to inconsistent human visual inspection standards while reducing manpower hours by 66%.

In warehouse and logistics management, AUO has implemented two key technologies: digital twin technology and smart automation. By utilizing digital twin systems, AUO can integrate virtual inventory with physical products. This integration allows real-time access to order information and product locations, without the need to be present in the warehouse. Thus, this system represents a seamless integration of virtual and physical elements, and solves the challenges of integrating outdated systems. The intelligent automation technology enables direct planning of optimized routes and real-time dispatch of autonomous mobile robots (AMR). This has improved warehouse and logistics efficiency by 30%, resulting in lower inventory levels and higher operational efficiency in warehouse and logistics management.

AUO University Cultivates Internal Cross-Disciplinary Experts to Accelerate the Pace of Digital Transformation

The university starts by establishing internal awareness towards digital transformation and smart manufacturing. AUO is committed to cultivating cross-generational technology talent. Through systematic planning of employees' learning and development roadmaps, AUO University implements diversified training programs, providing internal and external training resources, and encouraging employees to engage in continuous learning. This approach ensures the simultaneous development of professional knowledge and cross-disciplinary skills. In 2018, AUO University initiated its smart manufacturing talent development program, providing courses and external training from Taiwan AI Academy (AIA) to enhance employees' proficiency in data analysis and AI technical capabilities. Trained participants were empowered to apply their acquired knowledge in implementing AI solutions in their respective departments. The program also incorporated real-world projects into the classroom, merging academic expertise with practical discussions to address core issues and identify effective solutions. As a result, AUO University has successfully trained over 1,300 internal experts in AI smart manufacturing to date, implementing a total of 342 AI projects, establishing the university as a driving force behind the AUO biaxial transformation strategy.

In addition, AUO has been constantly organizing the annual "AUO Smart EXPO" since 2018, featuring remarkable achievements across various departments. The expo serves as a dynamic platform for colleagues to observe and exchange ideas, inspiring a mindset of manufacturing transformation. AUO is committed to driving digital transformation, shifting focus from scale and value competition to value transformation. AUO continues to invest in forward-looking technological innovation and research and development to strengthen its competitive edge, and aims to deliver high-value-added products and efficient, reliable solutions to global customers while actively seeking collaborations to explore further opportunities for innovation and sustainability.

TrendForce 2023 Infrared Sensing Application Market and Branding Strategies

Release: 01 January 2023

Format: PDF

Language: Traditional Chinese / English

Page: 164

|

If you would like to know more details , please contact:

|