Micro LED is considered to be the next generation display technology with its excellent performance in contrast, low energy consumption, quick response time and wide viewing angle. In January 2018, Samsung released the first Micro LED modular TV, “The Wall,” and other leading companies like Apple and Sony have also been investing in the technology development to push the application for end-market. If the obstacles of mass transfer technology and after process repairing could be overcome, it is forecasted that in five years Micro LED will be in the market. According to the estimation by LEDinside, the revenue of Micro LED and Mini LED will reach US$1.38 billion by 2022.

Brief introduction to Micro LED and its advantages

Micro LED is to make LED backlight thinner, miniaturized, and arrayed with the LED unit smaller than 100 micrometers and the accuracy is 10,000 times higher than conventional LED. In addition, each pixel is individually addressed and driven to self-emit without backlight. OLED is also self-emitting but with its organic materials. Comparing to TFT-LCD, OLED performs better in response time, viewing angle, flexibility, color display and energy consumption and therefore become popular among manufacturers. However, with more accurate color adjustability, longer luminous duration and higher brightness, Micro LED is considered the technology for pushing the quality of display after OLED.

For emission, the light can penetrate through the 3-5μm epitaxy to present good luminous efficacy after removing the substrate of Micro LED. If there is further progress for mass transfer technology, Micro LED could perform high ppi with semiconductor processing technology to control the wafer size in micrometer and high definition. When being applied in small sized displays on mobile phone and wearable devices, Micro LED would demonstrate its advantages.

Another advantage of Micro LED is its low energy consumption as Micro LED is without backlight module. The displays in use currently is highly power consuming and cause the issue of battery duration for mobile phone manufacturers. Micro LED could solve the problem and at the same time, improve the quality of display.

Ultrahigh brightness and nanosecond response time are two important features of Micro LED. Usually the display brightness should reach at least 82,000 lux nits when under direct sunlight. Micro LED could easily perform 5,000-10,000 lux nits while conventional LCD technology presents only softer light with its low luminous efficacy. Each pixel of Micro LED is constituted by several micro sized LED; theoretically the contrast could be infinite. And Micro LED responses 10 times faster than LCD.

Micro LED industry chain and its application for display

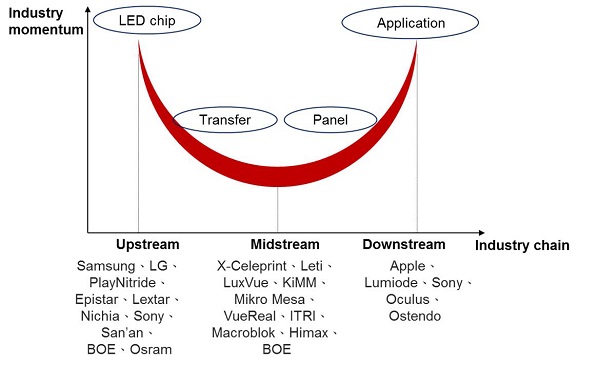

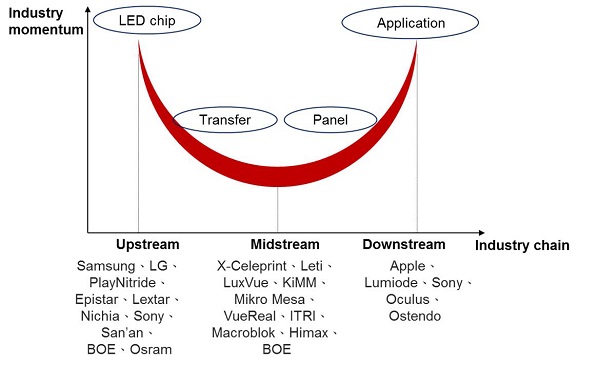

The industry chain for Micro LED includes LED chip, transfer, panel and applications. Currently the momentum gathered more on LED ship and application but not so much for the midstream process of transfer and panel production. Technologically speaking, Micro LED at the moment is limited by the issue of mass transfer and thus still some distance from mass production. Also the mainstream panel manufacturers are preparing for OLED instead of announcing their plan for Micro LED.

To grasp a view at the producers in the industry chain, Osram, Nichia, Epistar, PlayNitride and San’an are the upstream LED chip manufacturers; midtream firms include LuxVue, mLED and ITRI; Apple, Sony and Lumiode are companies of end market.

(Image: Micro LED Industry chain analysis, TRI 2018/05)

Wearable devices and extra-large TV are the two main Micro LED application based on the presented technologies. It is said that Apple is going to adopt Micro LED in its new Apple Watch and may launch more wearable products applying Micro LED. Meanwhile Sony and LG are targeting extra-large TV; Sony introduced its Micro LED TV, CLEDIS (Crystal LED Integrated Structure) at CES 2017, which achieve high performance in brightness, contrast and resolution.

To analyze from the output of display application, wearable devices such as smart watches may be the critical products to boost needs of Micro LED. The battery life of smart watches is a main issue as enhancing the display quality and performance will increase the power consumption. With the features of luminous efficacy and low power consumption, Micro LED may solve the problem of smart watches.

Other potential Micro LED products include VR/AR, indoor large displays, smart phones, panels and TVs. However, for small and middle size screen, OLED display is still the focus of many big companies and is taking over LCD. OLED may be perform weaker than Micro LED in energy saving and other display features, but cost and price are still essential when it comes to competition. According to LEDinside, there are still problems of technology and cost for Micro LED to solve before it could compete with LCD and OLED as the manufacturing process of LCD and OLED is more mature. Thus, the targets of Micro LED will be applications that current technologies cannot fulfil.

LEDinside forecasted that there will be development of various size displays. One feature of Micro LED is its emitting area is smaller than the module and it can be spliced to make extra-large displays, especially for massive signage for outdoor and public areas. In the market of extra-large display, price is not the most sensitive issue and therefore it could be the first commercial market for Micro LED to enter. Another one would the application of extra-small displays on wearable and AR/VR devices. With high brightness, low power consumption and fast response, Micro LED is perfect for AR/VR application; it could tackle the display problem under the sunlight, save energy and meet the need of high response when playing games.

According to the forecast of LEDinside, large size display will be the main application of Micro LED. It is estimated that the revenue of Micro LED application on large size display will reach US$1.98 billion by 2025, taking 68% of the total application and 10% TV penetration rate.

Conclusion

Since 2016, LED started to be used as backlight and entered the plateau phase with limited prospect. Micro LED had brought new expectation into the industry with its wide application and related produce including precision machinery, semiconductor manufacturing, testing and repairing. The mass transfer process is still the technological obstacle to be solved for Micro LED to achieve mass production. However, many leading producers put efforts in Micro LED research and have made breakthroughs in part of the development. It is expected that by 2H18, there will be high-end products entering the market and Micro LED is potential to become the next generation display technology.

At Micro LEDforum 2018, titled“Key Technology and Application Market – Transfer, Inspection and Drive Solution Boost,” LEDinside and attendees will explore the market trend and the solutions to tackle technology difficulties of Micro LED.

The event will take place on July 12th 2018 at NTUH International Convention Center in Taipei. Experts worldwide will join to holistically discuss Micro LED from the manufacturing process to end-market application. LEDinside is looking forward to welcoming professionals of the industry. Do not miss the last chance of early bird rate and register now on http://seminar.trendforce.com/Ledforum/2018/US/index/