Achieving Ultimate Precision: Solving Sensor Packaging Challenges

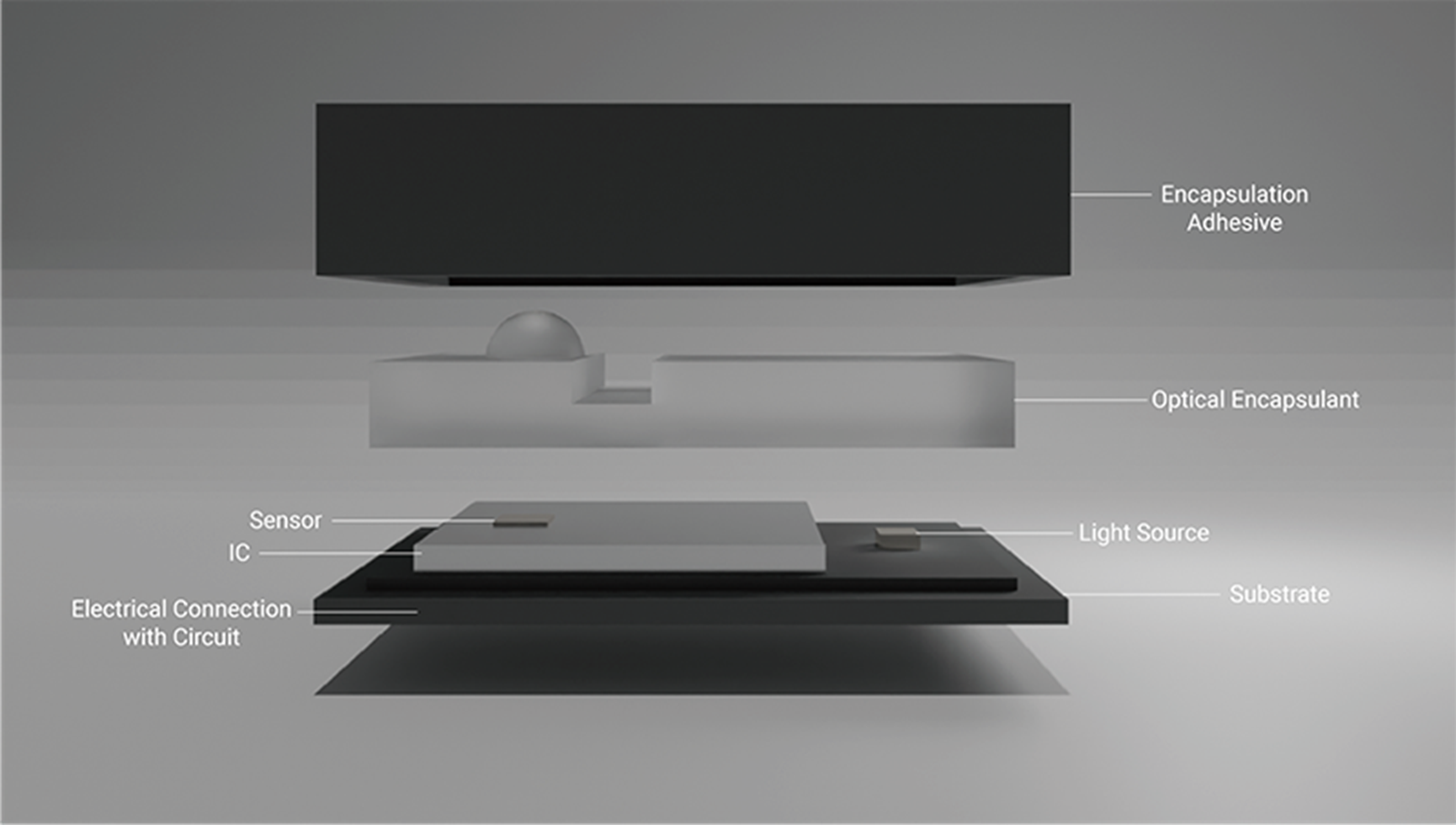

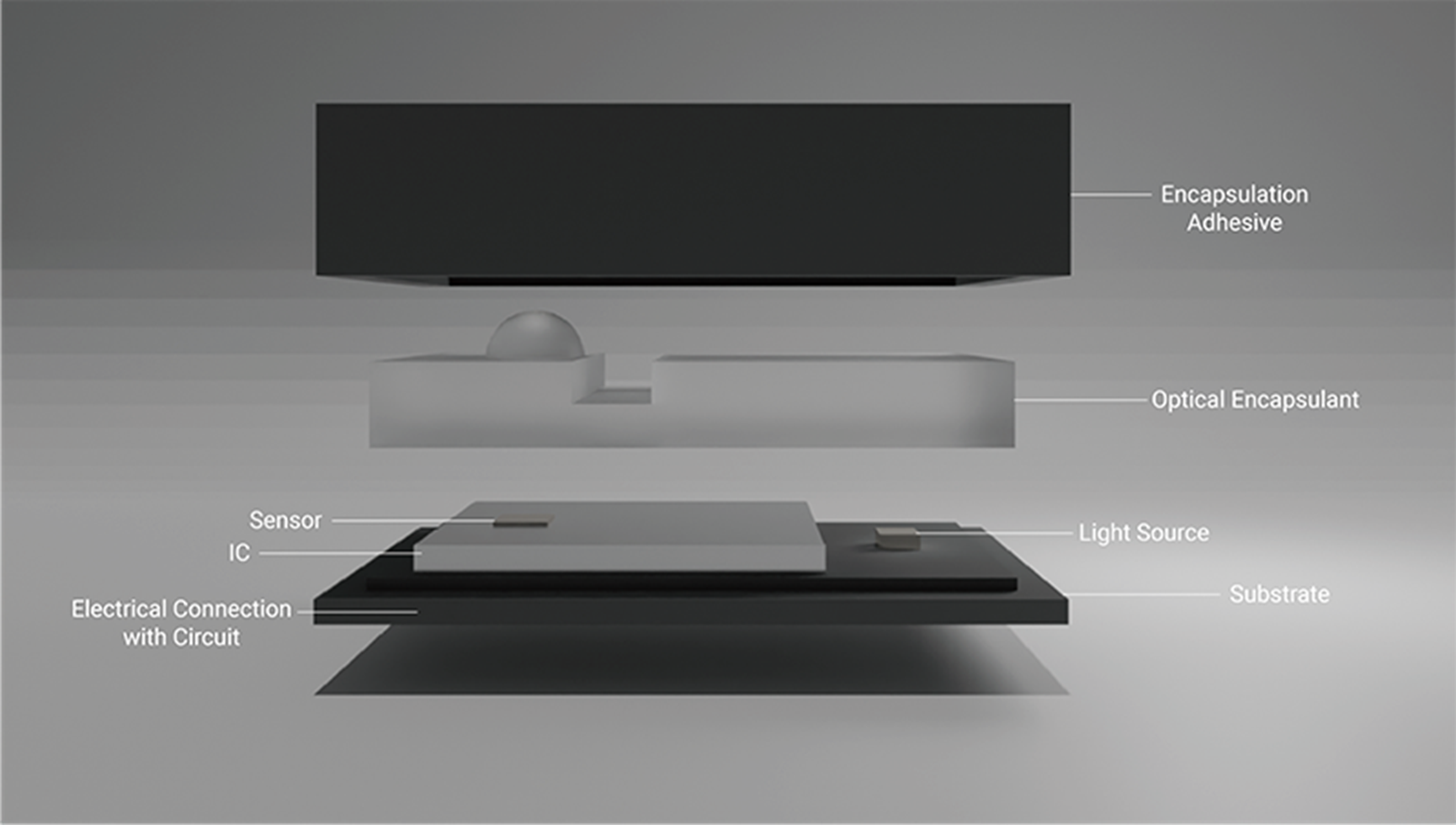

Precision in sensor packaging is not just about innovation—it’s about solving real-world challenges for our customers. From package design to internal chip and lens processing, every detail matters in optimizing optical transmission and reception performance. Brightek’s technology is designed to address critical pain points, ensuring sensors function with highest accuracy and efficiency.

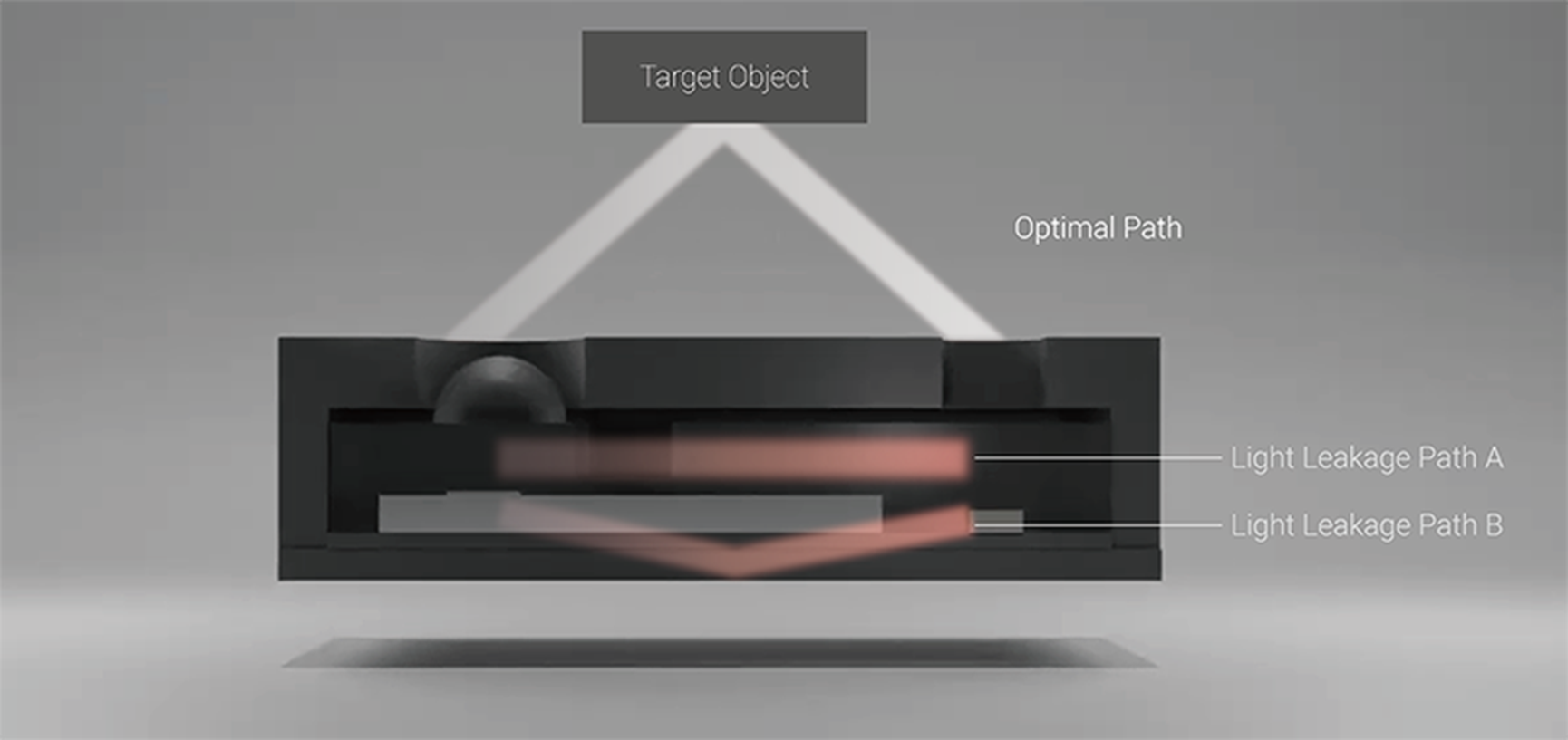

The Critical Role of Light Path Management

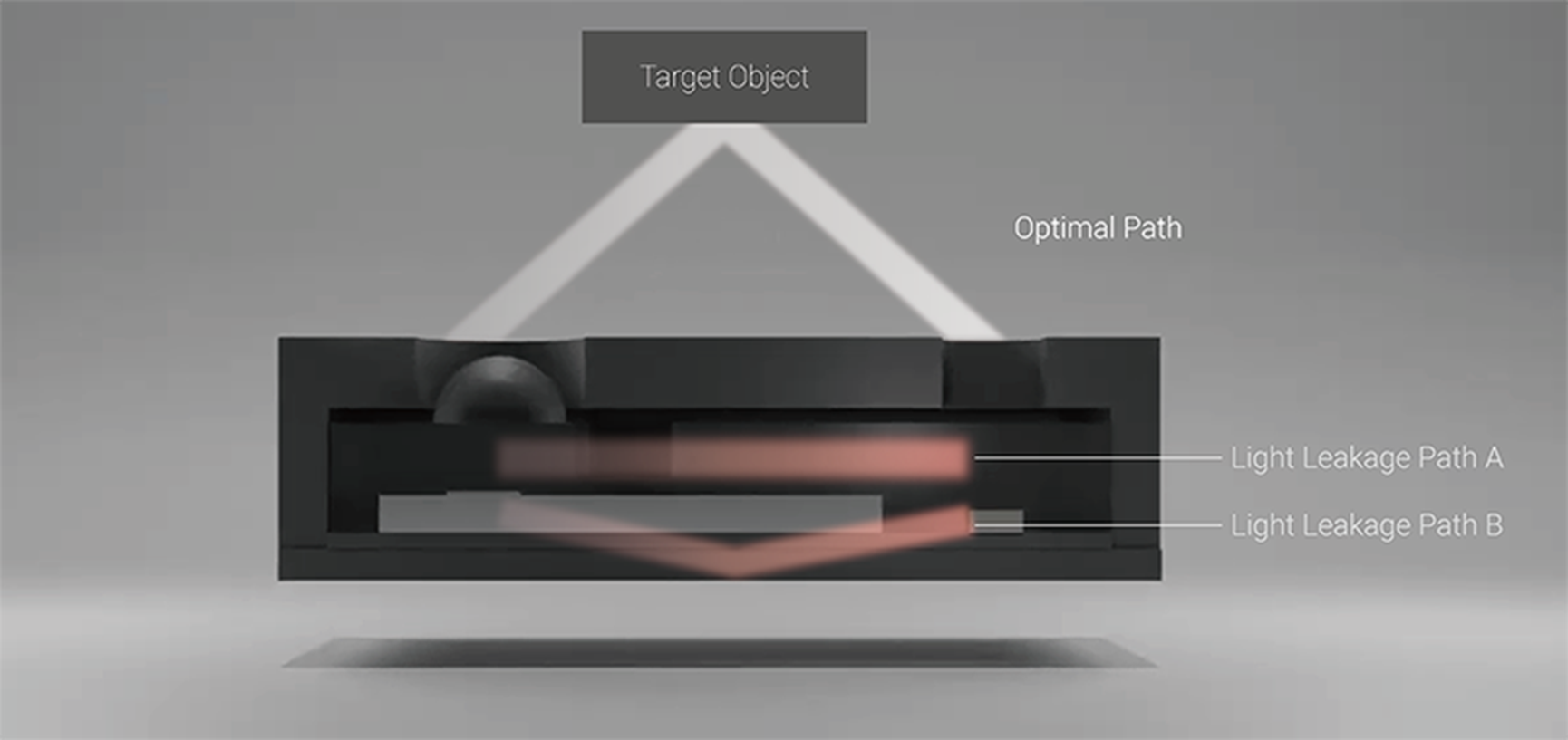

A sensor’s performance hinges on its ability to manage the light path between emitter and receiver. Even the slightest deviation can impact measurement accuracy, making it imperative to optimize every component. When the light emitted by the sensor passes through the lens, reflects off the target, and returns to the receiver, ensuring that this path remains undisturbed is the primary task. This requires the thorough elimination of optical leakage and interference.

Eliminating Optical Leakage for Superior Performance

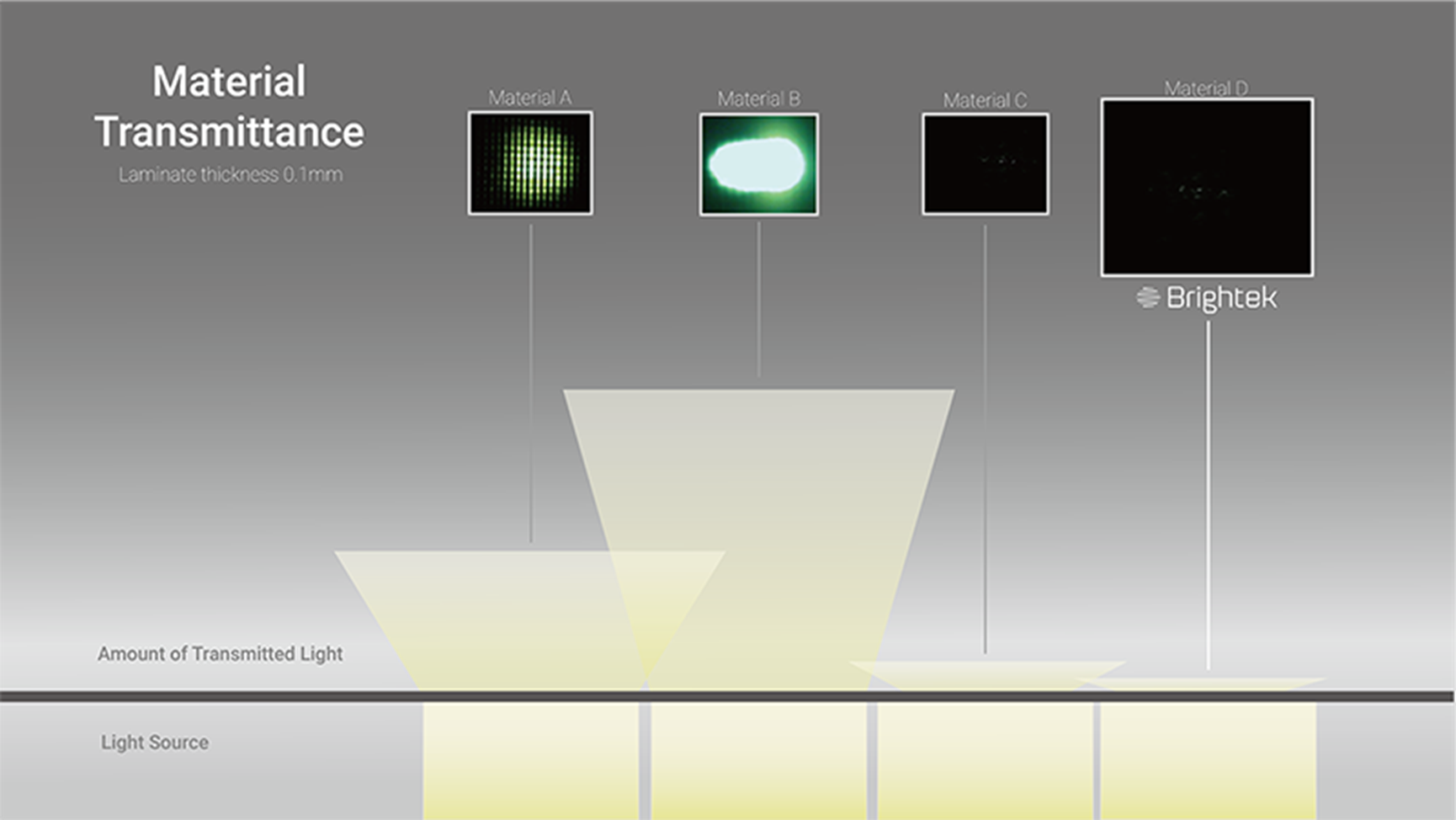

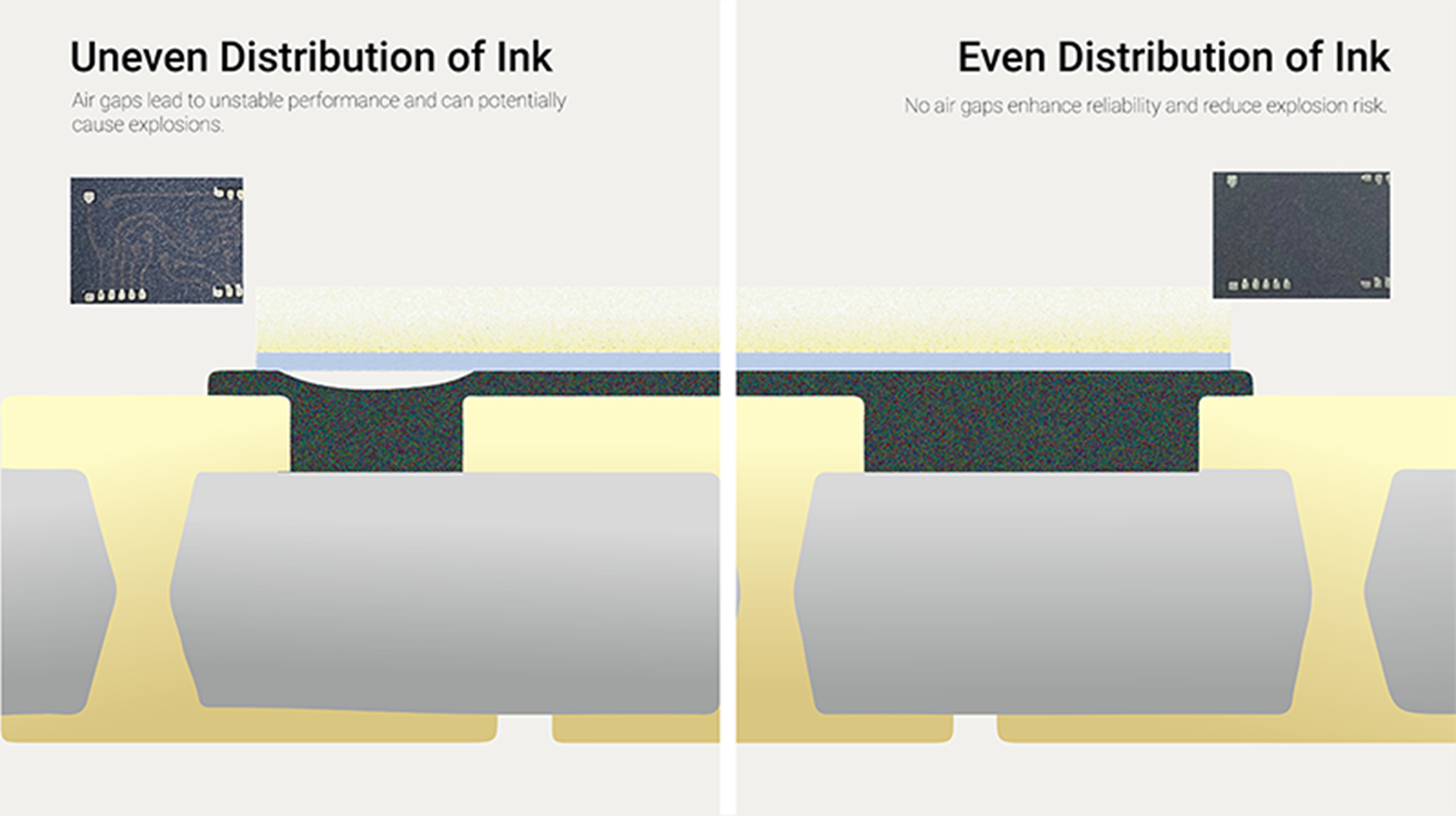

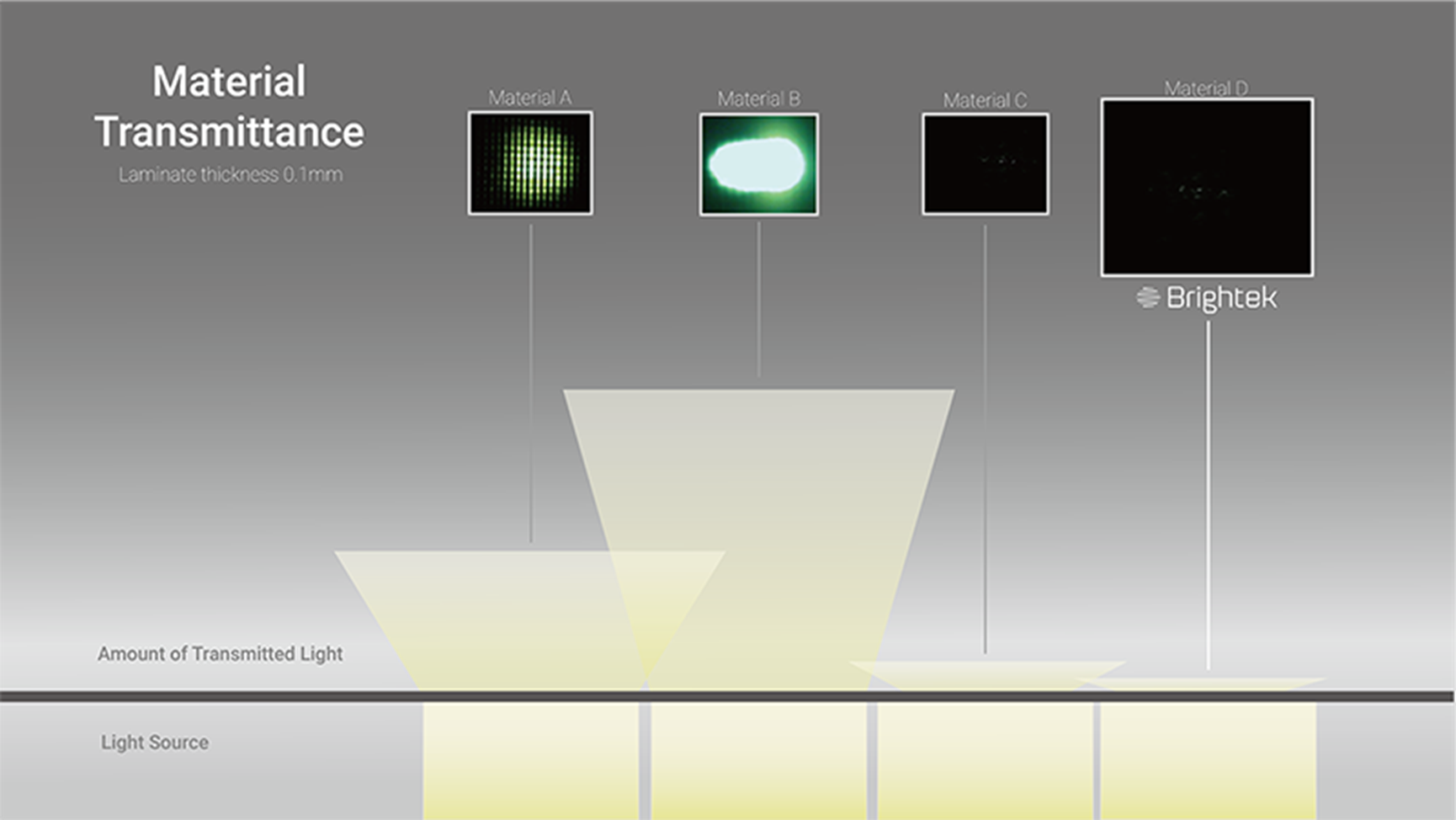

One of the key challenges in sensor packaging is preventing unwanted light leakage, which can disrupt accuracy. We address this through meticulous material selection and design enhancements:

-

Lightproof Substrate Materials: Prevents light leakage and ensures an optimal transmission path.

-

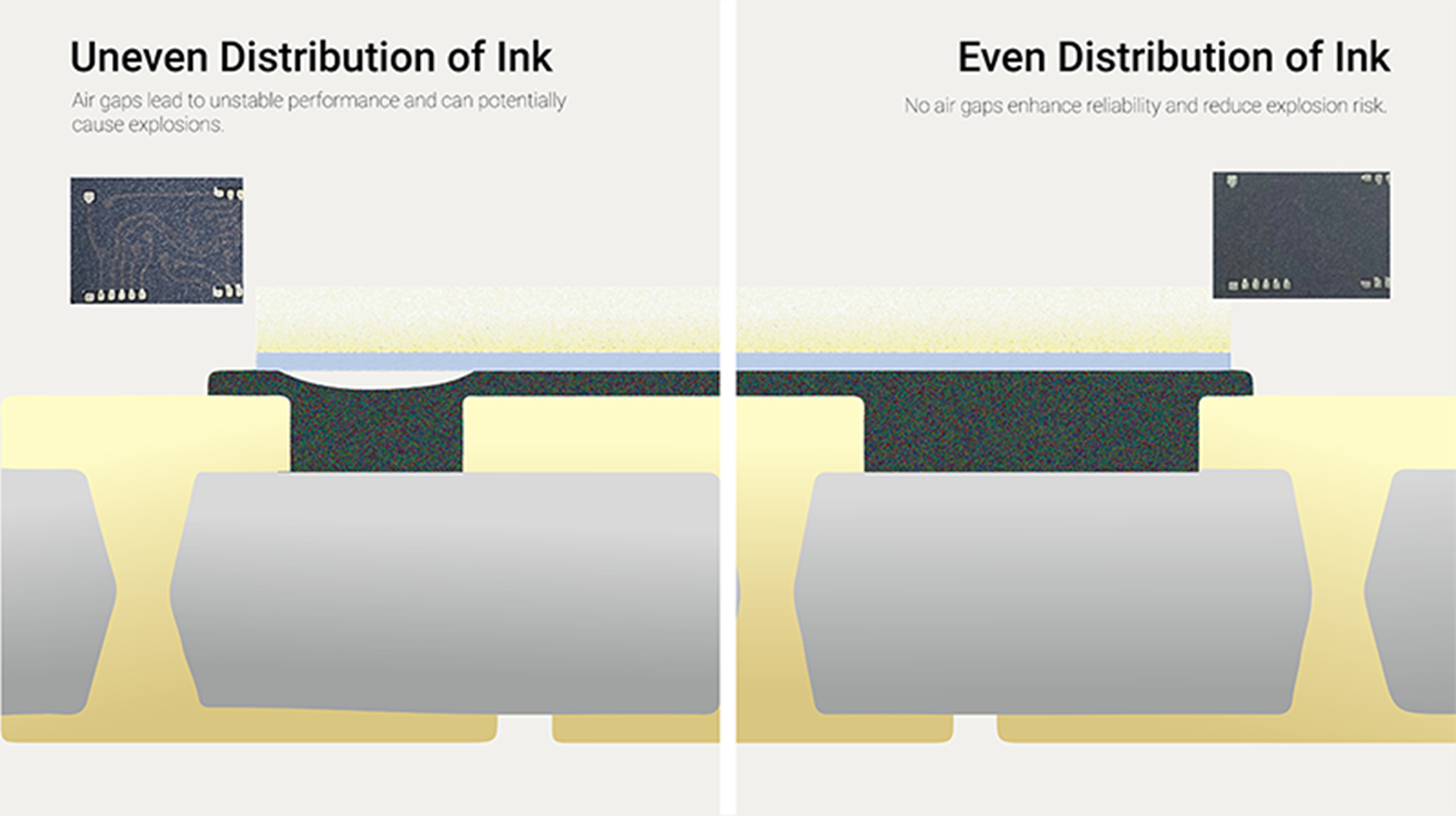

Chip Flatness Optimization: Treatment of the chip's bottom coating layer to eliminate gaps and bubbles, enhancing adhesion and stability.

-

Specialized Black Encapsulation and Casing: Blocks optical interference, ensuring that light travels along the intended path without affecting sensor sensitivity.

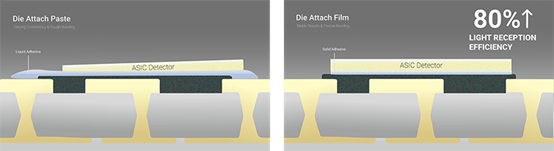

High-Precision Die Bonding for Unparalleled Efficiency

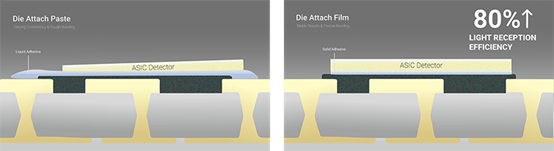

Die bonding is a critical step in sensor packaging, as misalignment can significantly affect light transmission. Traditional liquid adhesives can lead to chip displacement before curing, resulting in light efficiency loss. To combat this, Brightek employs:

-

DAF Die Bonding Technology: This advanced process enables precise chip placement and angle control, achieving over 80% light reception efficiency.

-

Minimized Adhesive Overflow: Prevents contamination and allows for miniaturized packaging without performance degradation.

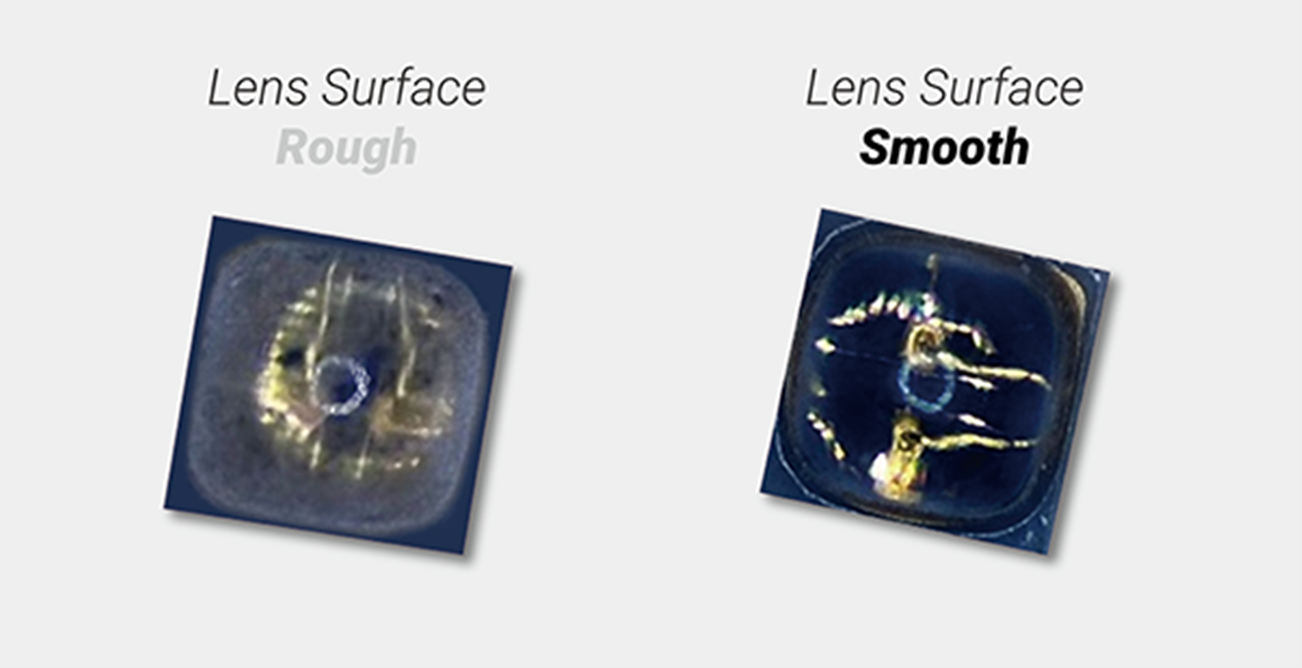

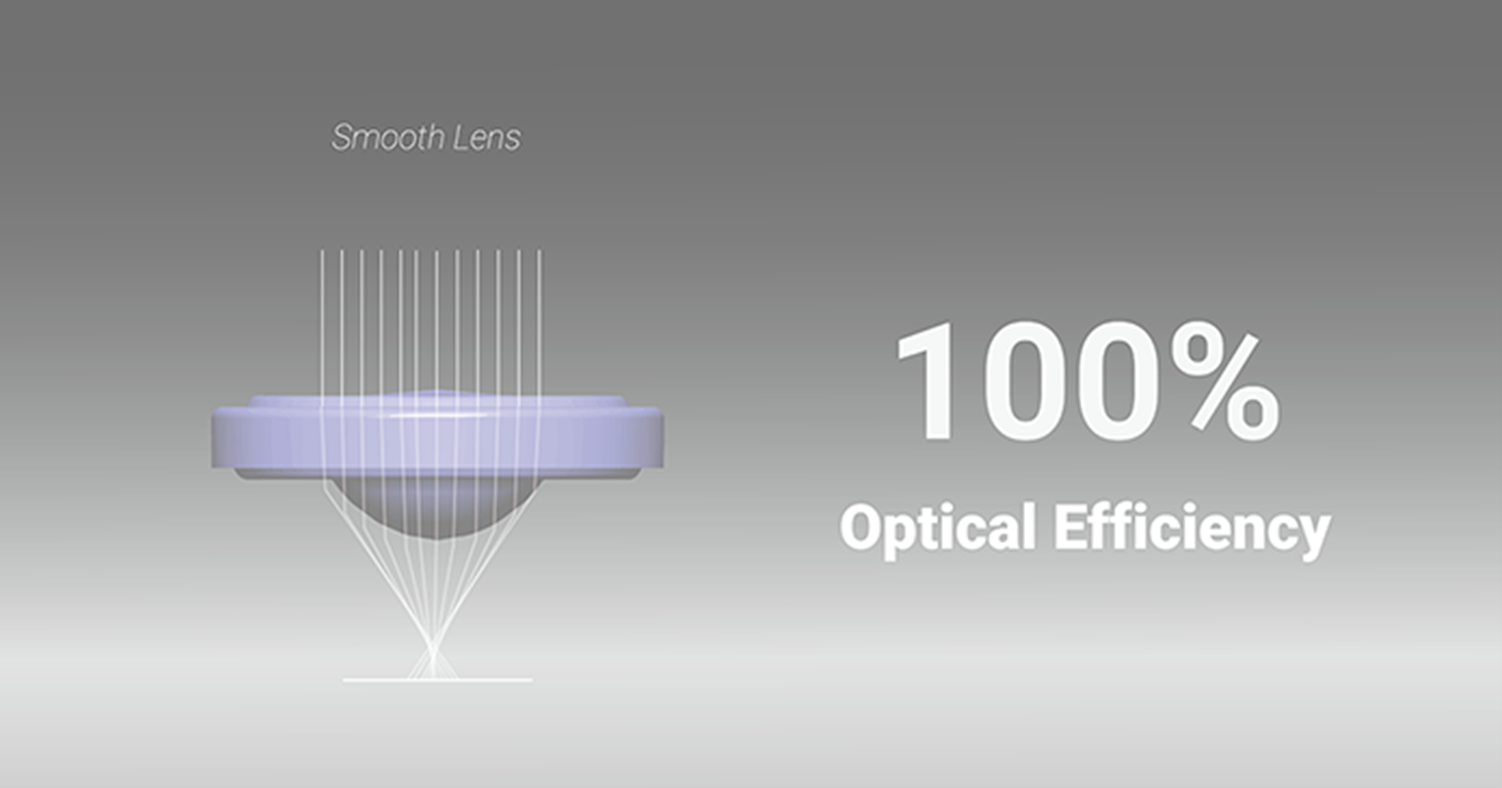

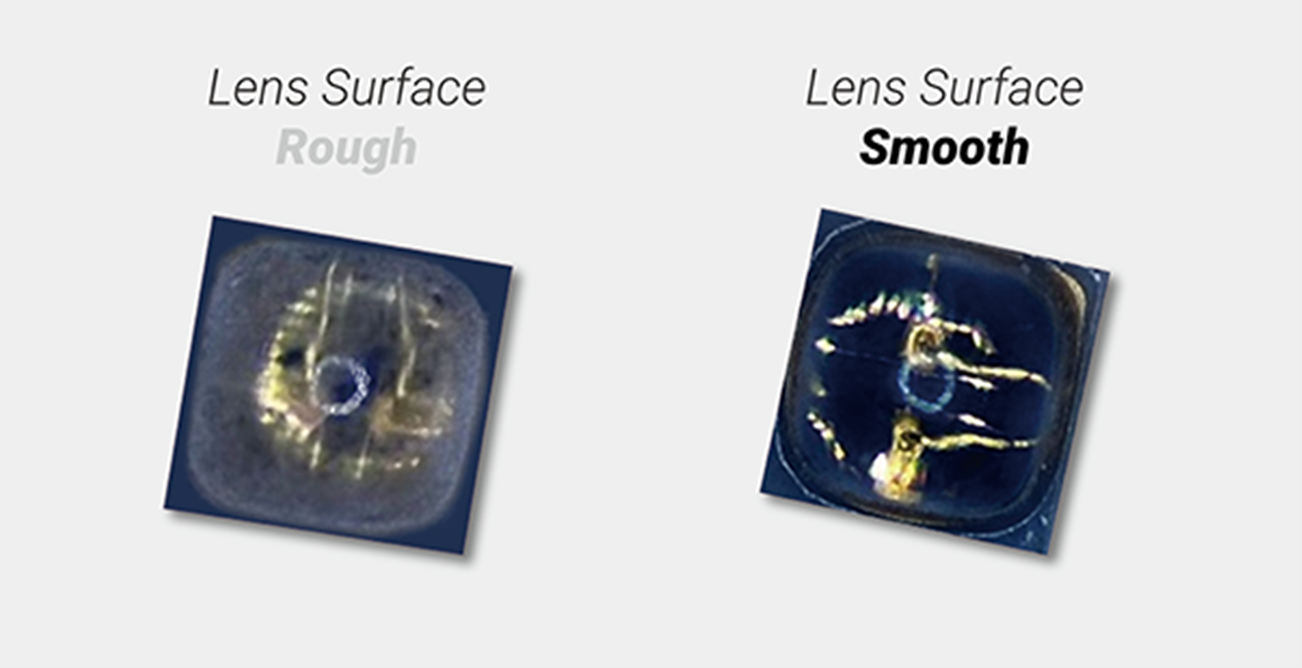

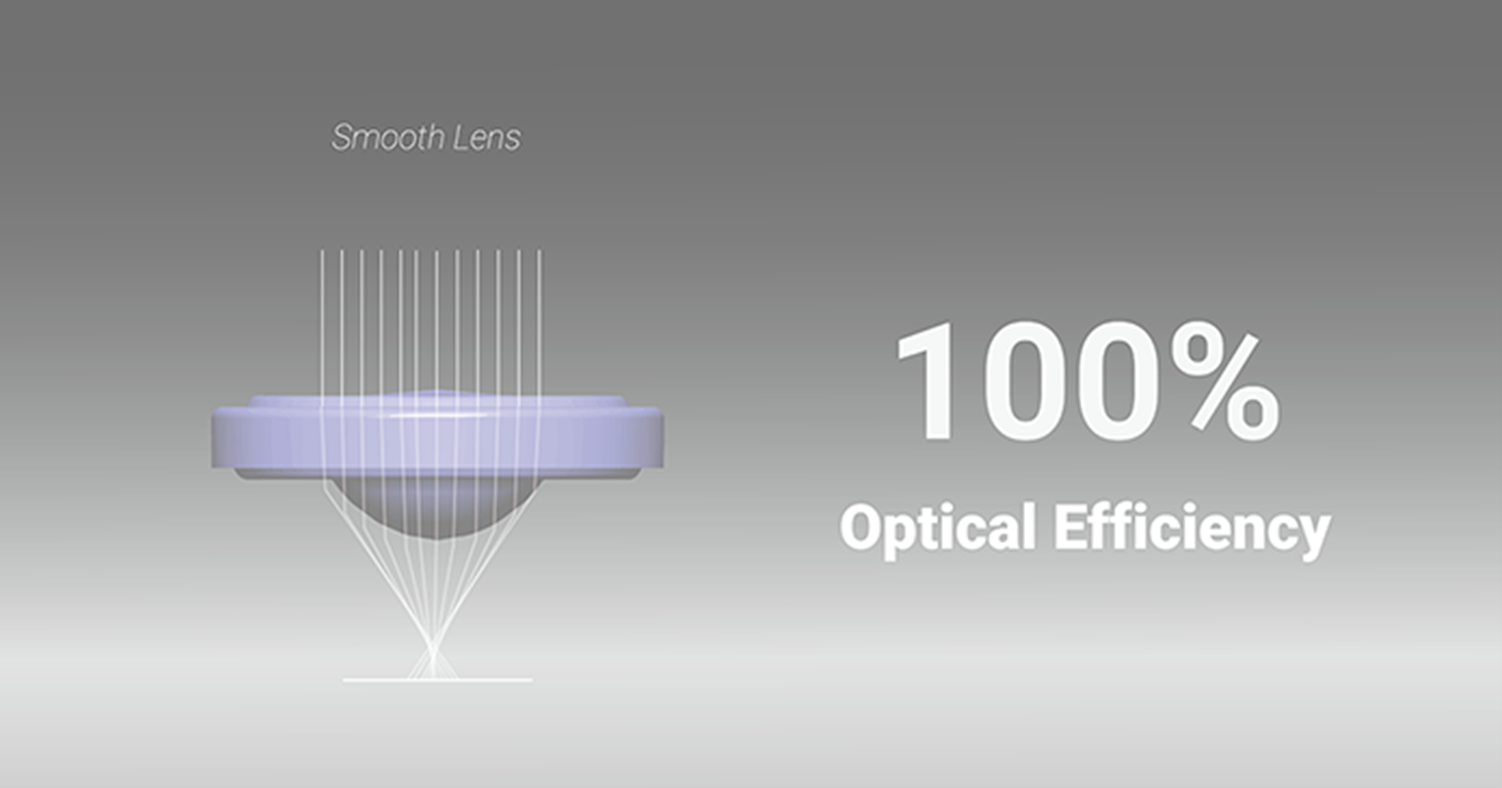

Advancing Lens Processing for Optical Excellence

The lens plays a crucial role in guiding light efficiently, and its surface quality directly impacts refraction and focus. To ensure top-tier performance, we leverage:

-

Optical Simulation Software: Used to assess lens shape and surface roughness.

-

Material and Injection Parameter Optimization: Reduces impurities and bubbles to minimize interference with the optical path.

-

RayFile Technology for Light Path Verification: Ensures that the actual optical performance matches the simulation results, enhancing reliability and accuracy.

Scaling Up with Brightek’s New Advanced Manufacturing Facility

Brightek’s commitment to innovation extends to our manufacturing capabilities. Our upcoming Nantong factory will house an advanced OPLGA optical sensor production line with a monthly capacity exceeding 60 million units. As a specialized OSAT (Outsourced Semiconductor Assembly and Test) facility, this new plant will allow us to manage the entire production process in-house, ensuring consistency and quality at every stage.

Enabling the Future of Sensor Technology

With extensive experience in precision packaging and a robust customization platform, Brightek continues to provide creative and reliable solutions for our clients. Our relentless pursuit of optical perfection is paving the way for future innovations, bringing sensor technology closer than ever to achieving the ideal of 100% transmission and reception efficiency.

TrendForce 2025 Infrared Sensing Application Market and Branding Strategies

Release: 01 January 2025

Format: PDF / EXCEL

Language: Traditional Chinese / English

Page: 196

|

If you would like to know more details , please contact:

|