GE sheds light on the company’s PFS phosphor red technology and developments in this latest blog entry.

|

|

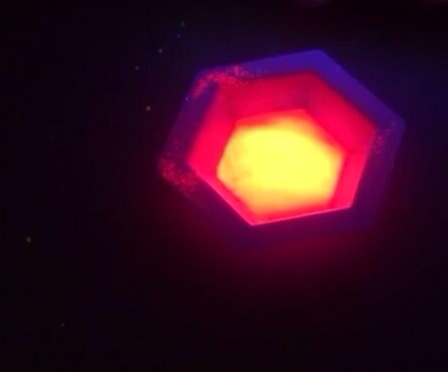

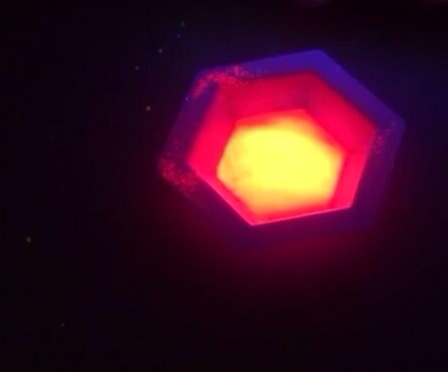

GE's PFS phosphor. (All photos courtesy of GE Lighting) |

Who invented the color red? Well, nobody of course. But in another sense, you might say that Nick Holonyak did in the modern era, when he created the red LED at GE’s labs in 1962. Now, materials scientist Anant Setlur has reinvented the color. Working with a team of researchers at GE Lighting and in Europe, Setlur found and patented a way leading to the perfect red light.

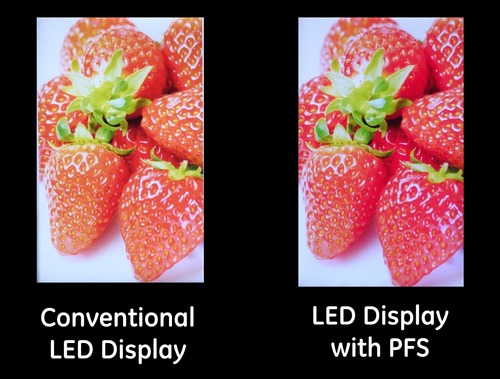

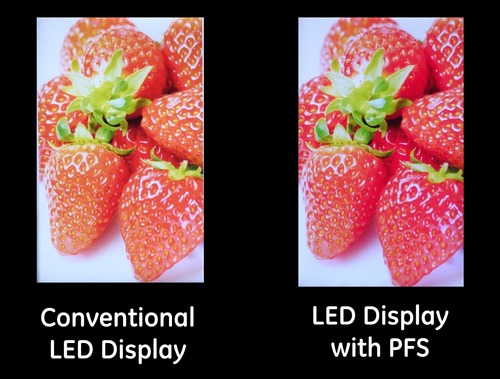

Setlur says that the new LED technology could “vastly improve” the color and crispness of LED and LCD displays for everything from smartphones and tablets to TV sets. “We were able to make LEDs emit the color red in a narrow band that makes everything look sharper and cleaner than the current state-of-art technology,” Setlur says. “It really makes the pictures pop.”

His idea is one reason why GE made the Thomson Reuters Top 100 Global Innovators list every year ever since its inception in 2011. The information and analytics firm released the most recent list on Friday. The list “honors the 100 corporations and institutions around the world that are at the heart of innovation as measured by a series of proprietary patent-related metrics.”

|

|

LED displays with PFS phosphor makes colors pop. |

Here’s why Setlur’s LED is a breakthrough. A large part of how we see colors boils down to the spectrum of light emitted by the source. (Although light appears white, we can see its colored components corresponding to the particular wavelengths during a rainbow.)

Of these colors, the red has been the most difficult to produce. Deep red makes other colors like green and yellow more vivid. But to the human eye, it appears dim since it moves quickly to the invisible, infrared part of the spectrum. “For a long time, we had to choose between brightness and appearance,” Setlur says. The result was a compromise that yielded displays and screens with a broad red profile with enough brightness, but also washed out yellows, greens and oranges.

Setlur and a colleague at GE Lighting started looking for a “Goldilocks” red that was just right. They found clues in a material called potassium fluorosilicate (PFS). “This material looks like pure yellowish powder that does not do much, but when you dope it with manganese, it emits a beautiful narrow red line,” he says. “We were able to coax that manganese to do the heavy lifting for us.”

|

|

This yellowish potassium flourosilicate powder manufatured in GE labs was key to making a better red light. Top Image: PFS radiates clean red light under a UV lamp in the lab. (LEDinside) |

GE has already licensed the technology to Japan’s Sharp Corp. and Nichia Corp. Both companies are manufacturing and packaging LEDs containing the PFS phosphor material for use as LED backlights in a wide range of LCD display products. Several display companies have recently launched tablets, smartphones and large screen TV’s containing these LED devices supplied by the two licensees.

Says Setlur: “It took us a few years to get there but soon everyone will be able to see the light.”