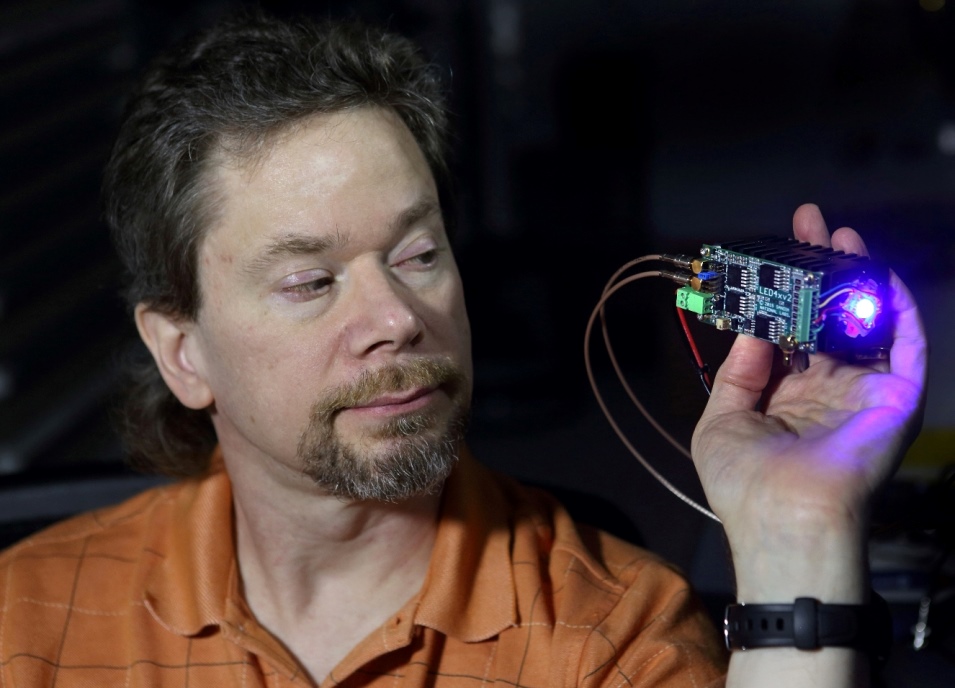

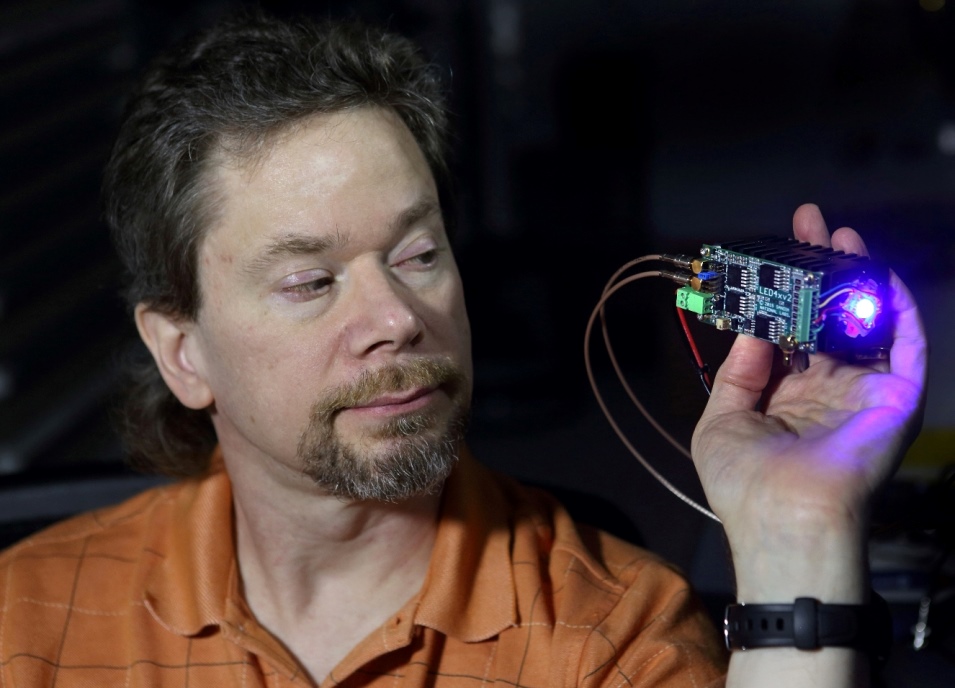

When Sandia National Laboratories electronics engineer Chris Carlen got enthusiastic about flashlights containing high-power light-emitting devices (LEDs), he didn’t expect his hobby to lead to the creation of a new, high-speed LED driver that delivers lighting performance that exceeds that of conventional sources at a fraction of the cost.

|

|

Sandia National Laboratories engineer Chris Carlen demonstrates the LED Pulser, which promises more cost-effective lighting for science, engineering and research and development applications. (Photo courtesy of Dino Vournas) |

The Sandia LED Pulser provides high-brightness, rapidly pulsed, multicolor light for scientific, industrial or commercial uses. In some cases, the LED Pulser can displace more expensive lasers.

“I had the idea a few years ago to see if high-powered multicolored LEDs in flashlights could be turned on and off rapidly by an electronic circuit to produce short light pulses similar to that of a 10-nanosecond pulsed laser or even down to one nanosecond depending on the LED,” Carlen said.

“It was more of a curiosity initially, but then something came up where a light source being used in a lab wasn’t working out, so I decided to try to make a quick prototype to pulse an LED, which worked out pretty well,” he said.

LED Pulser contributes to new scientific discoveries

The LED Pulser can be used in a variety of technical applications that normally demand far more expensive laser or arc lamp light (light produced by an electric arc) sources and optics. Sandia engineers already used it in several research studies aimed at developing the science base needed to design and optimize cleaner, more efficient engines that could in turn improve local air quality and public health and reduce the impacts of climate change.

In one of these studies, a high-speed backlit spray microscopy application, the LED Pulser delivered 50-nanosecond pulses at 200 kilohertz that “froze” the motion of liquid droplets. This allowed researchers to capture high-resolution images of atomization in a high-pressure diesel fuel-spray. Spray atomization and mixing profoundly affects combustion in spark-ignition and diesel engines, leading to greater efficiency and reduced emissions.

The LED Pulser also was used in a high-speed soot extinction imaging application. By generating high-intensity pulses matched to the camera exposure duration of two microseconds, they could quantitatively evaluate how diesel soot concentrations evolved.

The strong pulse intensity relative to combustion-generated light allowed full-field soot imaging at high frame rates, providing information needed to predict soot formation and oxidation processes.

A driving force for critical high intensity, short duration of pulses

Using custom electronic circuitry, the LED Pulser drives high-power LEDs to generate light pulses with shorter duration, higher repetition frequency and higher intensity than is possible with commercial off-the-shelf LED drivers. The device’s ability to combine high intensity and short pulse duration is critical, as simply decreasing the pulse duration while maintaining the same intensity as a continuously powered LED would reduce the light energy delivered per pulse.

Increasing the intensity with short pulses maintains the level of light energy delivered, which is essential for many applications. The LED Pulser can be an extremely economical replacement for lasers in some applications.

A single device can emit up to four different colors, each with independent pulse timing, from nearly the same area. This should expand the range of optical applications and lead to new imaging techniques.

Moreover, the low cost of this device will allow much broader use of diagnostic techniques throughout the scientific and engineering communities, leading to faster progress in developing an understanding and ability to predict important physical processes, Carlen said.

Working to improve device and overcoming technical challenges

Carlen is focusing on solving several technical challenges needed to improve the LED Pulser.

“There are still some things that can be done to try to make it better,” he said. “When dealing with extremely high currents in very short times, rather exotic techniques need to be used.”

Since the LED Pulser is designed to deliver as much power as possible, the circuits can drive the LEDs to the brink of destruction. To make a commercial version of the device, Carlen realizes he must improve the design to achieve low failure rates even at high power or reduce the delivered power to a level that yields an acceptable failure rate

Carlen is working on a LED Pulser that is 10 cubic inches in size and can produce 240 amps of drive current, for about 150 watts of peak optical power, depending on the LED used.

“What’s interesting about the Pulser is the power density, i.e., how much power it can deliver compared to its size,” he said.

He’s also trying to build a faster driver circuit. By improving the connection between the driving board and the LEDs, he hopes to achieve pulse durations of less than 10 nanoseconds. Another key to commercializing the device is designing a protection circuit that reduces the chances of destroying the LEDs.

R&D Magazine has named the LED Pulser as a finalist for the 53rd annual R&D 100 Awards, which honor the 100 most innovative technologies and services of the past year. Finalists represent many of industry’s leading organizations and national laboratories, and were selected by an independent panel of more than 70 judges.

“I didn’t anticipate the LED Pulser would become as popular as it has,” he said. “I’m just happy if it is helping to solve people’s problems.”