OSRAM SYLVANIA has expanded the Hillsboro manufacturing capabilities by adding the first advanced Surface Mount Technology (SMT) production line for manufacturing LED modules in the plant. OSRAM as the automotive lighting leader is pushing the transition to LED systems by investing in R&D and production capacities, infrastructure and talent to support the technology migration. Millions of dollars were invested in the plant for the new ISO class 8 Gray Room. LED modules produced from the new line are already on the road in the 2016 Ford Explorer LED headlamp, with other programs in development for the future.

|

|

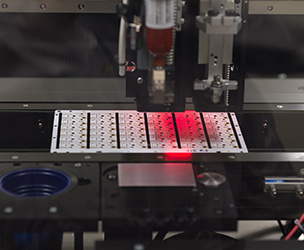

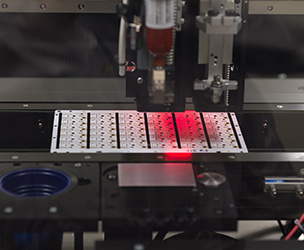

Osram Sylvania LED packaging. (Photo courtesy of Osram Sylvania) |

“OSRAM invested in industry leading electronics production equipment in all three global regions to serve our automotive customer base with world class production,” said David Hulick, global OEM SSL marketing director, OSRAM SYLVANIA, during the company’s automotive lighting showcase in the Detroit area this week, where it displayed its breadth of lighting solutions for OEMs and set makers. “Innovative designs and state of the art Surface Mount Technology lines, such as the new one installed in New Hampshire with tight tolerance LED placement capabilities, make it possible for OSRAM to deliver the precision, quality and supply that our global customers demand. With the implementation of this new production capability in the NAFTA region, we can better service our local customer base by providing the best local LED lighting production.”

Highlights of the automotive lighting showcase were the first LED forward lighting headlamp in a pick-up truck demonstrated on the 2016 Ford F-150, the LED headlamp with the new Hillsboro OSRAM LED modules in the 2016 Ford Explorer, and adaptive matrix LED headlights in the Audi A7.

“As the leading automotive light source designer and manufacturer, OSRAM Automotive Lighting provides OEM customers with a portfolio of top-quality interior and exterior lighting solutions, ranging from individual LEDs to standardized LED systems as well as HID systems, auxiliary light sources and advanced halogen products,” said Julian Dench, senior vice president and general manager, SP Americas Region, OSRAM SYLVANIA. “This production facility will allow us to immediately respond to all of our customers’ demands as a full service automotive lighting leader and deliver the future of LED automotive lighting.”

Coupled with sister facilities in Europe and Asia, this new North American investment advances OSRAM’s leading role in automotive electronics through a global quality-controlled (TS16949) automotive electronics manufacturing footprint. According to recent market reports, LED lighting adoption in the automotive category will rise sharply by the end of the decade.

“This new line has brought a lot of pride to our employees,” said Dariusz Laskowski, product line manager, who oversees the new SMT line at OSRAM SYLVANIA. “Everyone in the Hillsboro plant, whether they make the premium halogen headlights you see in retail stores or the LED headlamp in the new Ford F-150, is committed to quality because they know how important clear visibility is on the road. That mentality now extends at a local level to being able to produce the LED modules driving the advanced lighting technology in thousands of vehicles on the roads throughout the country, including the 2016 Ford Explorer.”