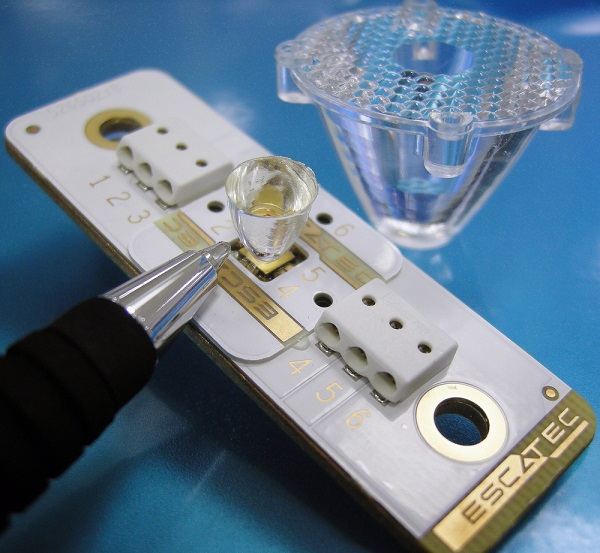

ESCATEC, one of Europe’s leading providers of contract design and manufacturing services, has designed a next generation, miniaturised TIR (Total Internal Reflection) lens for high brightness LEDs. About a twentieth of the size of current TIR lenses, ESCATEC’s next generation TIR lens is mounted directly onto the bare LED and secured in place with special clear optical glue. This secures the two items together with no air gap for optimal optical coupling, ensuring that the light is transferred from the LED to the TIR lens with minimal sideways losses, giving an optical efficiency of up to 95% of light being directed out of the front of the lens.

|

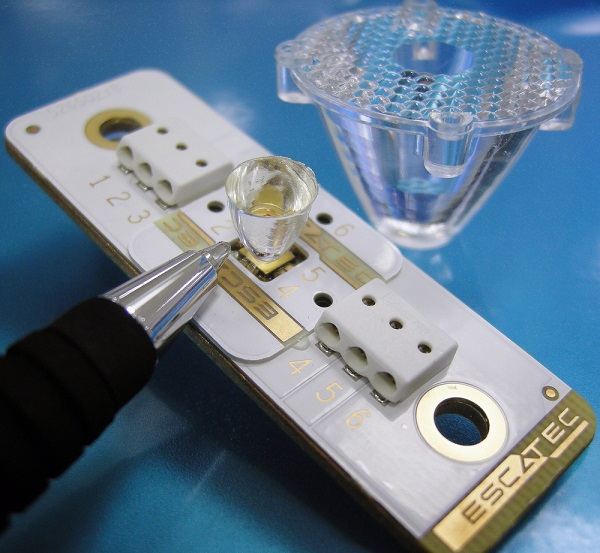

The new TIR lens match Escatec's Heat Spreader solution, providing high brightness while passively cool at power densities of up to 10W per mm2.(Escatec/LEDinside)

|

Current TIR lenses are designed to fit onto packaged LEDs and so cannot achieve the high level of optical coupling of the new design. They typically also have a much greater diameter of 20mm and height of 20mm whereas the next generation TIR lens can be as small as 4mm diameter and 4.5mm high. The new TIR lens can be made from PMMA, silicone or glass depending on how much heat it has to withstand.

The next generation TIR lens was developed to match ESCATEC’s recently launched Heat Spreader solution which enables high brightness LEDs to be packed closely together and passively cooled at power densities of up to 10W per mm2. The combined packing densities of the LEDs and TIR lenses sets a new standard for ultra-bright, compact, lightweight lighting solutions such as stage lights, searchlights and even microscope illumination. Not only do these new solutions require much less power but they also have a longer operational life of up to 50,000 hours compared to 2,000 hours for a comparable Xenon lamp.

ESCATEC has a reference design available with 20W LEDs fitted within an area of 1.4mm by 1.7mm that generates a collimated beam of 10W light power with only +/-12 degrees of dispersion.