The Flint Group and Air Motion Systems have partnered to develop, test and introduce a line of LED-curable low-migration inks for in-mold labels that meet the world’s strictest and most definitive regulations for inks intended for food-packaging applications.

According to officials, the new inks adhere to guidelines put forth in the “Swiss Ordinance” (SR 817.023.21), a piece of legislation introduced by Switzerland in 2010 (and revised multiple times, most recently in June 2015) that outlines substances/components deemed safe for use in the production of printing inks developed for food packaging, and that of similarly sensitive goods.

The Swiss Ordinance guidelines are designed to avoid situations where, if ink were to “migrate” into a product and contaminate it, consumers would potentially be harmed; going a step further, it also mandates the acceptable migratory properties of any elements/substances on the list of approved potential ink ingredients on a PPM level, to ensure that consumers are at no risk.

|

|

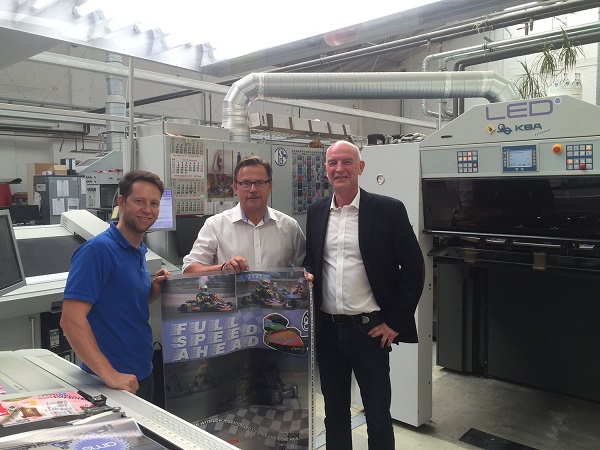

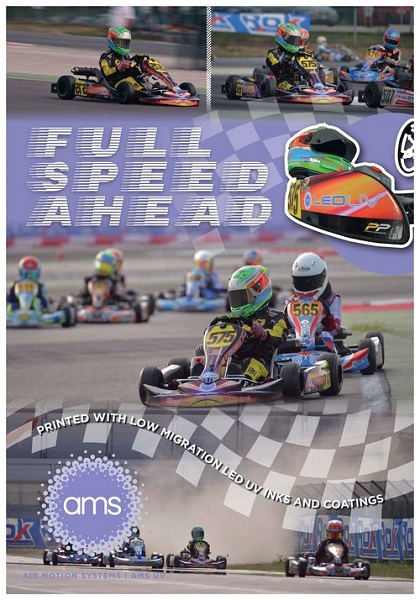

Flint Group's Richard Wilson (center) holds a poster printed with new LED-curable low-migration inks and coatings for in-mold labels while Königsdruck's Olaf König (right) and a press-team member join him. The new inks were cured using an XP9 LED module from AMS.(Flint Group/ LEDinside) |

Because regulations around the world vary greatly, the “Swiss Ordinance” is considered the most stringent and thorough set of rules to specifically address printing inks for such applications.

The LED-curable inks can be used on paper and plastic in-mold label substrates; they recently were tested at Königsdruck in Berlin, Germany, on a KBA Rapida 106 six-color press with coater, equipped with an XP9 LED UV curing module from AMS. Testers chose sheets of 47 micron in-mold stock for the trials, and ran the press at normal speeds (12,000 SPH). Low Migration Plastic Coating, which is water-based, was used to finish the sheets, and both the inks and coating were cured with a single “hit” of LED-UV light from the XP9 module, stationed end-of-press, emitting 385nm UV light evenly across the substrate surface via collimating optics.

Flint Group’s Richard Wilson said the tests confirm that the entire low-migration printing process for in-mold labels can be completed using LED inks and LED-based UV curing systems from AMS – the initial goal was to ensure that AMS’s system could cure low-migration Opaque White LED ink on in-mold label stock. The company chose to partner with AMS to develop and test the new inks because its systems offer the highest curing intensities available on the market today, while boasting a host of other economically and environmentally friendly benefits.

|

AMS president Steve Metcalf noted: “Customers curing in-mold labels with standard UV setups struggle with excessive heat from the lamps, which distorts the sheet. So printers tend to slow press speeds and reduce the energy output of the lamps to avoid the problem. Hence, speed and power are limited, and production is not at full potential.”

He continued: “The new process can be completed 100% with ‘one hit’ from a single AMS XP9 lamp, at normal production speeds, because of the coolness of the LED energy; doing so essentially removes all heat from the process, resulting not only in faster production speeds with better assurance of cure, but in a ‘flat stack’ for easier processing of the pile downstream.”

The LED-curable inks for in-mold labels will undergo additional testing in the coming weeks; the line is currently available for review, and will be available market-wide next year.

Low-migration packaging, by definition, does not contain chemicals/elements that could migrate and thus affect the taste, appearance, smell, safety or composition of the goods contained within. It also is produced in a manner that eliminates the potential of contamination during all stages of the production process.