According to the latest report of LEDinside, a division of TrendForce, while conventional LED components are used for backlight, Micro LED and Mini LED technology have been gradually used for self-emitting in displays of consumer electronics. Every LED will then stand for a pixel, increasing the number of LED wafers used.

As the technological bottlenecks being solved and the costs decreasing, Micro LED and Mini LED may have a chance to be adopted by display products. Even if there is only a small number of products using the technology, it will still be a remarkable contribution to the revenue of the entire LED industry.

Therefore, LEDinside estimates that when related products become commercialized, the revenue of Micro LED and Mini LED (excluding transfer process) will reach US$1.38 billion by 2022, and further increase to US$2.891 billion by 2025.

|

|

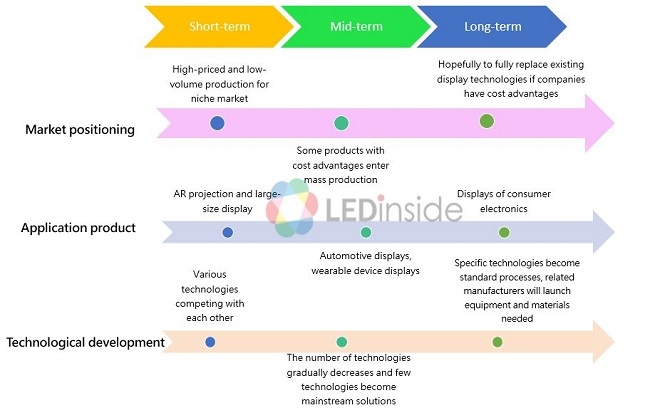

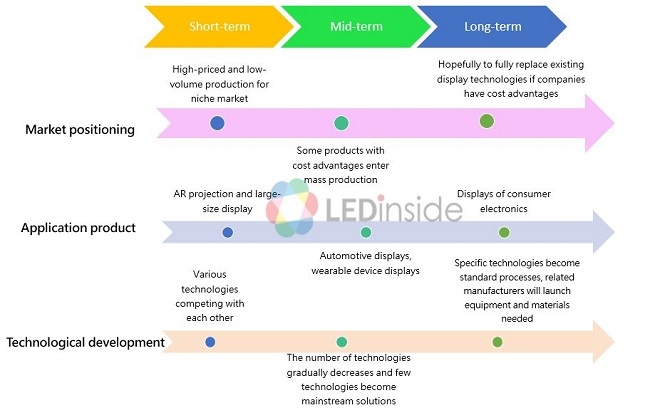

Application and Technology Roadmap of Micro LED (Source: LEDinside) |

Where are the application markets for Micro LED in the short- and mid-terms?

Some applications have a chance to adopt Micro LED technology in the next three years, including AR projection devices that require high-brightness, extra-large display panels such as digital LED displays, and televisions. The production volume of these products may increase gradually.

In terms of the overall competitive landscape in the display industry, LEDinside has noticed that some Japanese and Korean manufacturers want to introduce Micro LED technology for market segmentation, especially in the areas of extra-large TVs and commercial displays, etc. At present, extra-large displays over 75-inch have high costs due to intrinsic limitations of the manufacturing process, if traditional LCD and OLED panels are used, thus making the selling price of end products very high. However, if Micro LED technology is adopted, extra-large displays can be made by splicing, which may fill gaps in existing display technologies.

In addition to the extra-large display, it is also observed that the development of Micro LED projection applications such as AR projection is also in full swing. Micro LED technology can achieve high brightness and power saving, and can also be used to make smaller light machine modules, so it will have a chance to become the new mainstream display technology after Micro LED technology matures. LEDinside estimates that the total shipments of AR products will reach 4 million units in 2025, and 18% of them will use Micro LED projection technology.

What are the advantages of AR products using Micro LED technology? First of all, AR products have high requirements of size and weight, and must be easy and convenient to use. Therefore, projection technology uses micro displays to integrate all the pixels of the images onto a one-chip integrated circuit module. Among them, the projection technology LCOS, DLP need additional light source to produce images. Micro OLED displays will enable pixels’ self-emitting directly on the integrated circuit, reducing the light source and the overall weight, but the brightness is relatively low; the brightness is easily influenced by the external ambient light as well, reducing the contrast of display. Therefore, with better brightness and contrast, Micro LED technology will outperform Micro OLED displays, although they are both self-emitting.

The market outlook of Micro LED applications in the long-term

In the long term, if Micro LED technology wants to cut into the mainstream display market, costs reduction and production efficiency improvements will be primary goals. Only when key breakthroughs are made in technology and costs can Micro LED have a chance to entirely replace existing display technologies.

In order to make Micro LED products, LED companies need to reduce the size of LED chips to below 100 μm. Therefore, the companies need to purchase new equipment for the whole processes from LED epitaxial wafer design to wafer manufacturing, such as MOCVD equipment with higher uniformity, exposure machines with higher resolution, and laser for the transfer process, etc. This will largely increase the companies’ capital expenditure and depreciation costs. In addition, economies of scale cannot be reached in the initial stage, so the unit price of a single Micro LED wafer will be 5-6 times higher than that of a traditional LED wafer. As equipment is gradually amortized and the yield rate is improved, it is expected that the cost of Micro LED will decrease year after year. After five years, the unit cost of Micro LED will have a chance to be similar to traditional LED.

As for the mass transfer of Micro LED chips onto the receiver substrates, major LED companies have been developing various transfer technologies. Due to the relatively large number of these technologies, it is still difficult to judge which one will become the mainstream in the future.