University of Texas at Dallas researchers and their international colleagues have developed a method to create Micro LEDs that can be folded, twisted, cut and stuck to different surfaces. The research, published online in the journal Science Advances, helps pave the way for the next generation of flexible, wearable technology.

The research team created a detachable Micro LED with flexibility, aiming to fulfill the growing demand for bendable, wearable electronics. Researchers develop the flexible LED through a technique called remote epitaxy. To make it detachable, researchers added a nonstick layer to the substrate. The added layer, made of a one-atom-thick sheet of carbon called graphene, prevents the new layer of LED crystals from sticking to the wafer.

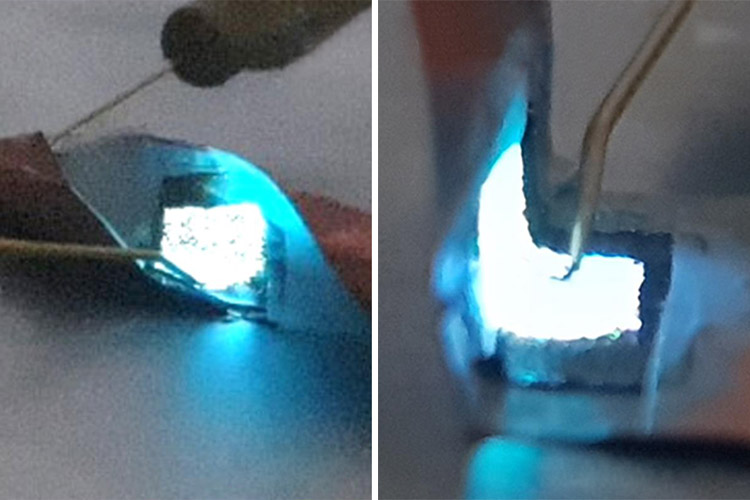

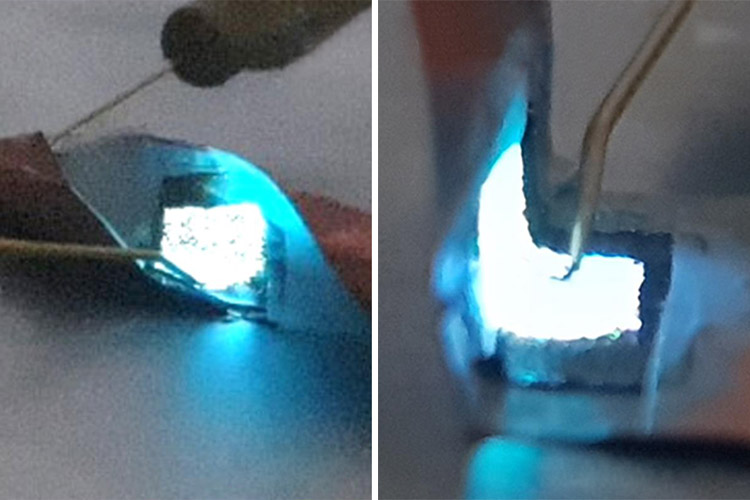

(Image: University of Texas at Dallas)

Colleagues in South Korea carried out laboratory tests of LEDs by adhering them to curved surfaces, as well as to materials that were subsequently twisted, bent and crumpled. In another demonstration, they adhered an LED to the legs of a Lego minifigure with different leg positions. From the testing results, researchers said bending and cutting do not affect the quality or electronic properties of the Micro LED.

The team is seeing a bright future for the technology covering applications in wearable devices, clothing and flexible lighting. The fabrication technique also offers another advantage that the Micro LEDs can be used repeatedly as they can be removed without breaking the underlying wafer substrate.