Recently, Canada-based VueReal has announced that it has made a breakthrough in the research of flipchip microLED structure. High yield rate and low cost can be achieved, and its yield rate can surpass 99.9%.

Currently, the yield rate of most flipchip microLED structures in the market is not high. Besides, the manufacturing process is not simple. The sensitivity of ESD is high. As a result, the production cost of display is quite high.

VueReal has focused on the development of vertical chip microLED process. Simple device can be produced, with yield rate up to 99.9996% and size below 8 μm.

In order to solve the problem of existing product, VueReal has developed a flipchip microLED with its expertise in the vertical device field. This microLED has most of the features of the vertical microLED, including simple process, high yield rate and smaller size.

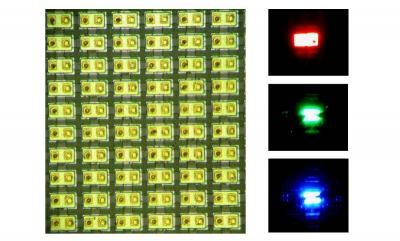

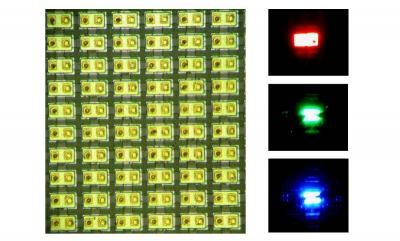

▲VueReal Flipchip microLED (30x15 um2), with almost all the area emitting light.

According to the introduction, the traditional flipchip microLED process is based on a two step mesa process. The process is twice as long as the vertical devices. Besides, it makes the major mesa smaller, and a mechanical weak point in the integration process at the joint border may be created.

According to VueReal, currently the flipchip yield rate of the competitors is far below 90%. VueReal’s flipchip yield rate is higher than 99.9%. In addition, due to more automated production line, higher yield rates can be reached. It means repair and process cost per display can be reduced.

Owing to VueReal’s internal capacity, the flipchip microLEDs can be developed and offered for third-party applications. Currently, it is licensing its flipchip structure to microLED manufacturers. Moreover, it will adopt VueReal microVue™ inspection system for complete inspection on defect and performance of microLEDs in order to increase yield rate and lower cost.

(Writer: LEDinside Janice; Image Source: pixabay)