Today the U.S. Patent and Trademark Office officially granted Apple a patent that relates to using various materials for providing input and output for an electronic device. More specifically, the present disclosure is directed to using piezoelectric material or electroactive polymers for receiving input and providing haptic output for wearable devices such as VR gloves, straps, watch bands, body suit or other clothing and electronic devices like glasses, an HMD, iPhone, rings, a MacBook and more.

Many traditional user input devices, such as keyboards, have a fixed or static layout, which limits the adaptability of the device. Additionally, traditional input devices may be rigid and substantially detached from a user, thereby limiting the functionality of the input device.

Apple's invention is directed to deformable haptic structures used within a wearable device such as a three-dimensional input system (e.g., such as a glove or other wearable input device) or other electronic devices like a MacBook.

The wearable device includes a flexible fabric having a first portion and a second portion positioned adjacent to a user. The wearable device further includes a haptic structure positioned on the flexible fabric and positioned between the first and second portions. The haptic structure includes electrodes enmeshed within a compliant layer.

The wearable device further includes a processing unit configured to generate an electrostatic force among the electrodes. The electrodes may be configured to produce haptic effects at the first and second portions by selectively deforming the compliant layer in response to the generated electrostatic force.

Apple notes that the electroactive polymer includes at least two electrodes separated by a compliant layer. The electrodes may be a conductive silicone rubber or other appropriate deformable material that flows or conducts electrical current. The compliant layer may be a non-conductive and flexible silicone or other appropriate material that substantially impedes the flow of electrical current between the electrodes.

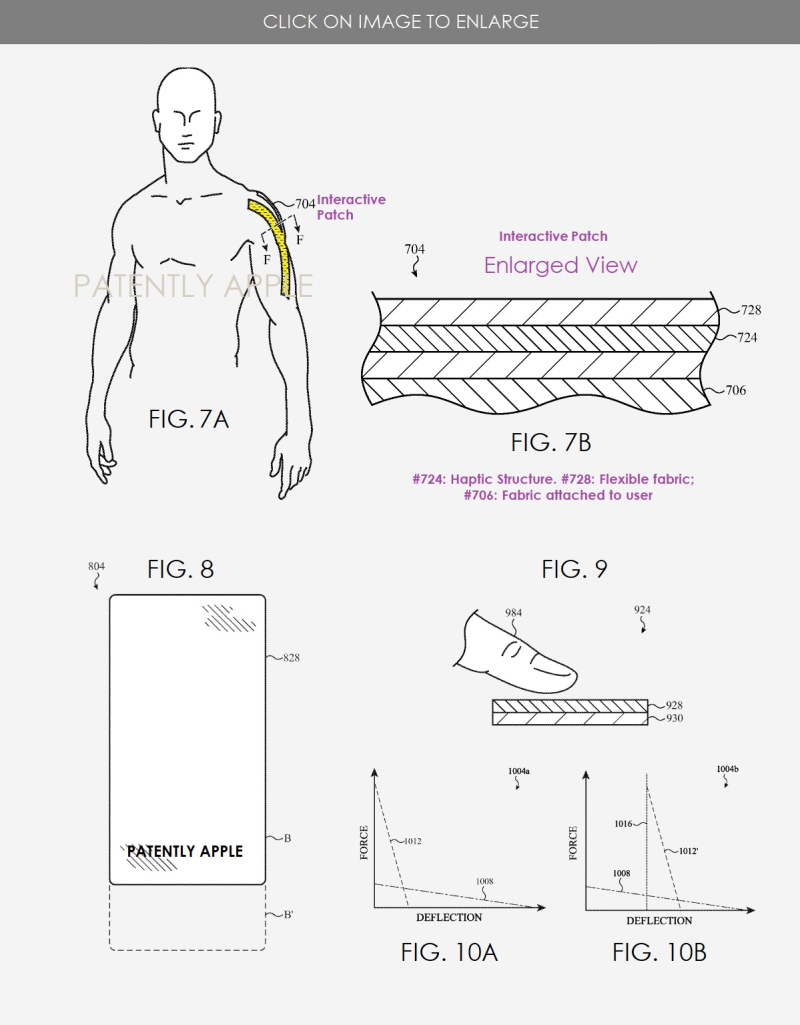

Apple's granted patent FIG. 7A depicts a sample interactive patch attached to a user via a wearable device like clothing; FIG. 7B depicts a cross-sectional view of the interactive patch of FIG. 7A, taken along line F-F of FIG. 7A.

Apple's patent FIG. 8 above depicts a sample interactive suit attached to a user; FIG. 9 depicts a haptic structure having an electroactive polymer and a strain-sensitive material; FIG. 10A depicts a force-deflection curve of the electroactive polymer and strain-sensitive material of FIG. 9, according to one embodiment; FIG. 10B depicts a force-deflection curve of the electroactive polymer and strain-sensitive material of FIG. 9.

The haptic structure includes many diverse applications within wearable devices. In one embodiment, the haptic structure may be, or form a component of, a band, strap, fabric, or other securement mechanism of an electronic device. The haptic structure may expand and contract (due to movement of the electrodes within the deformable capacitor) to conform the securement mechanism to a shape of a user. This may allow a watch band, for example, to conform to the shape of user's wrist or a virtual or augmented reality glove to conform to the shape of a user's hand.

Going a little deeper, Apple notes that conforming the flexible fabric to a shape of the user may enhance the tactile sensations experienced by the user, for example, because an increased surface area of the user may contact the flexible fabric and thus experience the associated tactile effects.

More broadly, the haptic structure may be configured to alter the offset to produce particular haptic effects. For example, the haptic structure may be deformed in a manner such that the flexible fabric encloses a volume of fluid (e.g., air) between the flexible fabric and the user.

For example, the flexible fabric may translate relative to the user to produce a pressure sensation of an object represented within the virtual environment when the user interacts with the object using the electronic device.

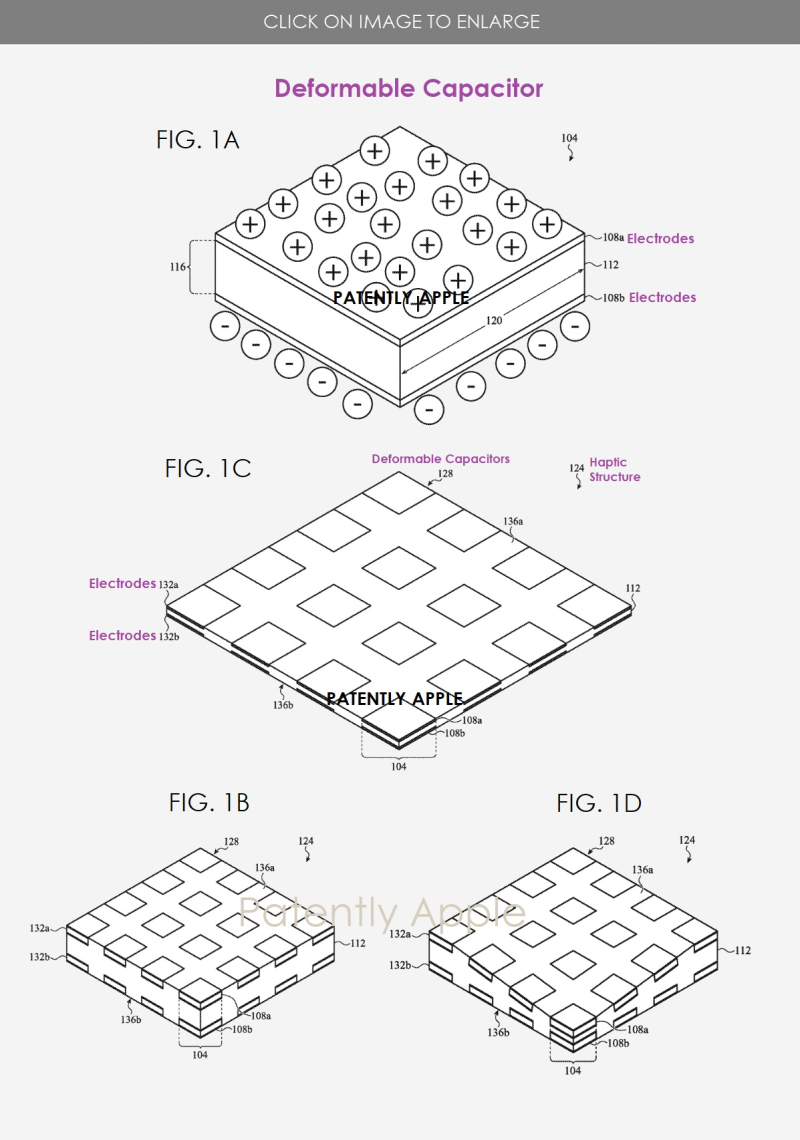

Apple's patent FIG. 1A below depicts a sample deformable capacitor; FIG. 1B depicts a sample haptic structure having one or more deformable capacitors; FIG. 1C depicts the haptic structure of FIG. 1B, in a state in which the haptic structure is globally deformed; FIG. 1D depicts the haptic structure of FIG. 1B, in a state in which the haptic structure is locally deformed.

For more details about this invention, especially how it applies to a possible future MacBook keyboard or Apple Watch, review Apple's granted patent

11,127,547 . A few of the inventors include:

Paul Wang: Architect, Product Design

Alex Lehmann: Product Design Engineer (Finite Element Analyst)

Zheng Gao: Was a Sr. Product Design Manager at Apple and is now with Tesla.