"Porotech, a pioneer in the microLED field, is honoured to have been invited to participate in the ""Metaverse X Technological Evolution X Application Innovation"" Forum. Porotech shared their game-changing technology - DPT® (Dynamic Pixel Tuning®) in the forum, and how to use wafer to wafer bonding technology to achieve the commercialization goal of high-yield, low-cost, full-colour microLED mass production, truly bringing microLED into everyone's life. "

Micro LED has been hailed as the new star of the next display generation due to its excellent performance. However, the supply chain has yet to enter a mature stage for microdisplays due to the boundaries of related process technologies, failing to enter large-scale commercial applications.

"In 2020, Porotech developed a unique material, PoroGaN®, which enabled the world's first InGaN red light display, facilitating the use of InGaN materials for all three colours of R/G/B displays without unnecessary losses in the manufacturing process, which is a revolutionary first step for process simplification. In 2022, we replaced the traditional spatial light mixing method with field sequential colour mixing in the original technology. We later announced our proprietary DPT® (Dynamic Pixel Tuning®) technology, where only a single LED can produce monolithic full-colour displays. With these rapid adjustments, MicroLED production has become more efficient, thinner and lighter displays, all while while maintaining excellent image quality.

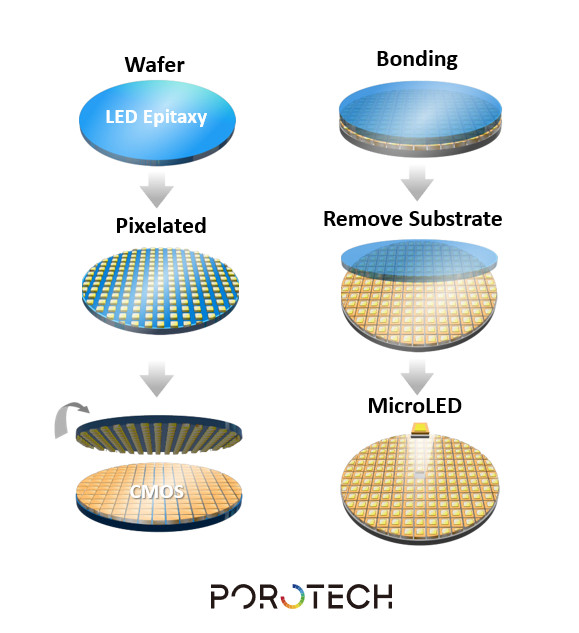

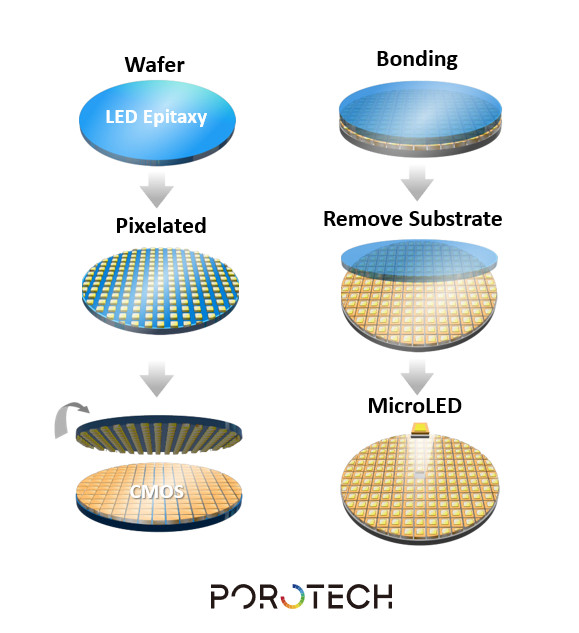

""Porotech is one of the few suppliers in the market that can provide 8-inch wafers or 12-inch GaN on silicon."" Daniel HE, Director of Product and Market Development at Porotech said. The traditional microLED transfer yield has always been a challenge faced by the industry's common bottleneck. Still, Porotech uses its exclusive PoroGaN® 8-inch wafer and 8-inch wafer-to-wafer bonding technology to omit redundant processing and keep the lowest loss rate, which not only improves the yield rate but also reduces the cost by 4 to 5 times compared with the traditional process. Introducing these technologies effectively lowers the technical threshold for mass production and realizes ""bringing microLED to the Real World"", providing the key to next-generation display changes."

Porotech's innovation and technological breakthroughs continue beyond theory. The company expects to mass-produce a 0.12-inch microdisplay by 2025. By then, it will be able to catch up with the growth of microLED wearable devices from 2025 to 2027 and complete the transformation of display technology. In addition, Porotech is actively participating in multiple projects, cooperating with European and American customers to jointly promote the development of microLED technology in various application fields. These plans are expected to transform Porotech's technical advantages into reality and provide more possibilities for future microLED applications.

"Porotech's participation and technological breakthrough mark a new milestone in the microLED industry and highlight Porotech's leading position in the AR field. Its DPT technology will pave the way for the commercialization of microLED and bring us a n infinitely improved display experience. Porotech is paving the way of the microLED revolution and continues to provide more advanced display technologies to consumers worldwide.

We look forward to having in-depth discussions with industry colleagues at this LEDinside forum to shape microLED's future jointly."