A Coherent 140 W diode laser extends the range and battery lifetime of handheld rangefinders.

Lasers have been used as distance-measuring tools for decades. As early as 1962, scientists at MIT bounced high-power ruby laser pulses off the moon to measure its distance from the Earth. In 1969, the Apollo 11 astronauts left retroreflector arrays on the moon that astronomers at Lick Observatory used to get even higher accuracy measurements of lunar distance. These reflectors are still in use today with earth-based lasers!

Today, the miniaturization in microelectronics that has given us smartphones and wearable fitness devices has also shrunk laser-based rangefinders into handheld devices. Laser-based rangefinders can measure the distance to a point over a range of several hundred meters and are used in sports like golf, archery, and hunting. They are also found in commercial applications, such as in construction, civil engineering, and manufacturing. In manufacturing, the measurement of distances using lasers is vital for ensuring that products are assembled consistently and according to high-precision standards.

BUILDING A BETTER RANGEFINDER LASER

Range-finding systems are typically based on diode lasers or fiber lasers. Diode lasers are usually preferred for portable or handheld devices because they are smaller, lighter, more robust, offer higher electrical efficiency, and typically cost less than other laser sources. But there are many different applications that can be classified as “laser distance measurement” – from scanning LiDAR systems for autonomous vehicles to rangefinders for golfers. The types of diode lasers that service these are similarly diverse.

Coherent manufactures diode lasers for all these applications (as well as fiber lasers for LiDAR systems). For consumer rangefinders, we have developed a source specifically designed to deliver the balance of performance, cost, and various practical characteristics (like weight or battery lifetime) demanded by this market.

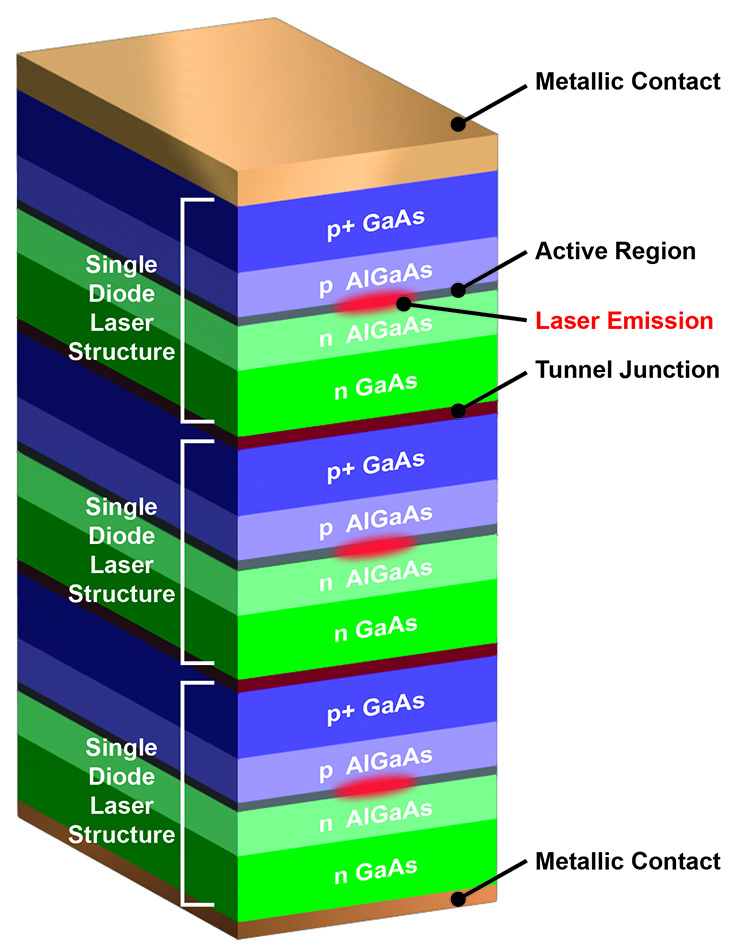

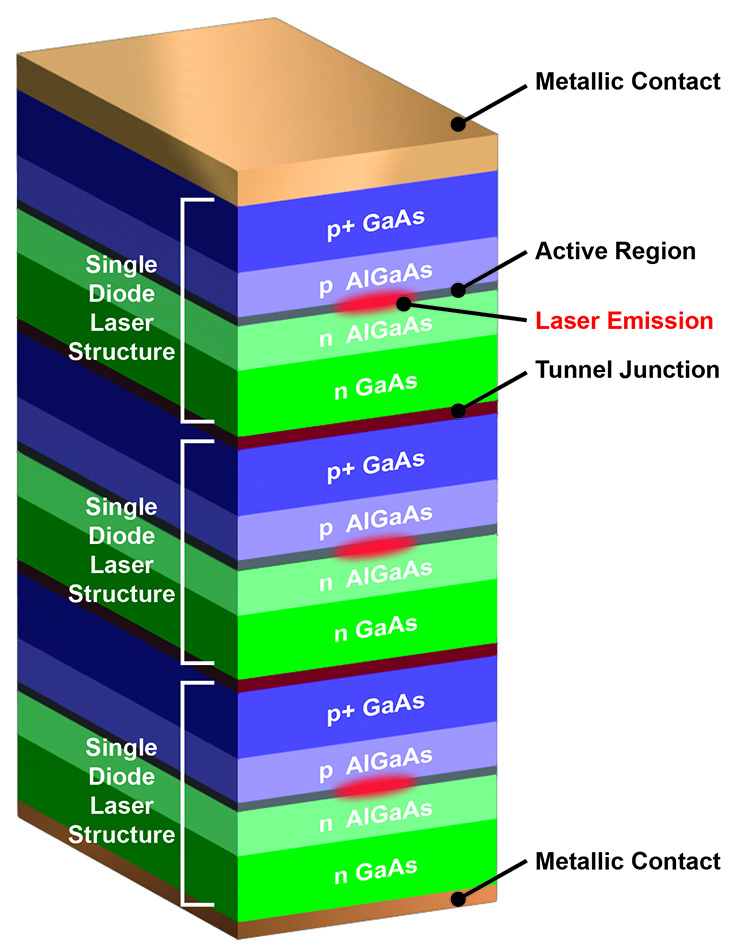

Specifically, the Coherent SS905A13-TO-01 is a 905 nm, edge-emitting laser diode featuring a triple-junction structure. This means that three separate laser emitters are tightly integrated within a single chip to function as a unified source.

A triple-junction diode laser vertically stacks three separate laser emitters on a single chip. Each laser is separated from its neighbor by a “tunnel junction.” This layer is necessary to avoid forming a p-n junction between each laser. But it must be thin enough so that electrons can quantum mechanically “tunnel” through it to allow current flow. Overall laser efficiency depends strongly on tunnel junction performance, and Coherent has developed methods that minimize loss in this layer, resulting in superior performance.

This triple-junction configuration results in significantly higher output power, up to 140 W of peak power, compared to conventional single-junction diode lasers of comparable size and electrical characteristics. This approach is not suitable for continuous or high-duty-cycle pulsed operation because of the high heat generated by closely spaced laser junctions. But it is ideal for short-pulsed, low-duty-cycle applications, like rangefinding, where the laser is activated only briefly.

The Coherent SS905A13-TO-01 offers several advantages over competing diode lasers designed for rangefinding – even those that also use the triple-junction structure. For example, the SS905A13-TO-01 is up to 10% more efficient than competitive products. This extends the battery life and gives the product engineer flexibility with power source and device “packaging” considerations.

Additionally, the Coherent laser exhibits remarkable power stability when subjected to temperature variations. This ensures accurate and reliable measurements even when there are substantial changes in the operating environment.

WHY 905 nm

Most rangefinders and LiDAR systems in consumer applications operate at either 905 nm or 1550 nm. Coherent manufactures diode lasers at both these wavelengths (and many others), but we believe 905 nm is a more cost-effective choice for rangefinders.

One reason for this is that 1550 nm lasers are made using InP, while 905 nm lasers are made from GaAs. InP substrates and fabrication are more costly than GaAs, while the power conversion efficiency for GaAs chips is 45% as compared to less than 10% for InP components. These factors increase the value of 905 nm diodes relative to competitive products.

The supporting componentry for 905 nm lasers, such as the detectors, offer additional cost advantages that directly impact product pricing. This is because 905 nm lasers can use detectors made from widely available (read inexpensive) CMOS silicon, while 1550 nm lasers require much more costly InGaAs-based components.

Rangefinding is just one of the laser-based sensing technologies finding increased use in products as diverse as LiDAR, smartphones, VR headsets, and consumer-grade devices targeted to industrial markets, such as building and construction. Coherent remains committed to developing lasers and other photonic components that deliver the mix of price and performance required to make these applications a practical reality. We accomplish this by harnessing our unique combination of capabilities in semiconductor materials, lasers, and optics.

TrendForce 2024 Infrared Sensing Application Market and Branding Strategies

Release: 01 January 2024

Format: PDF

Language: Traditional Chinese / English

Page: 172

|

If you would like to know more details , please contact:

|