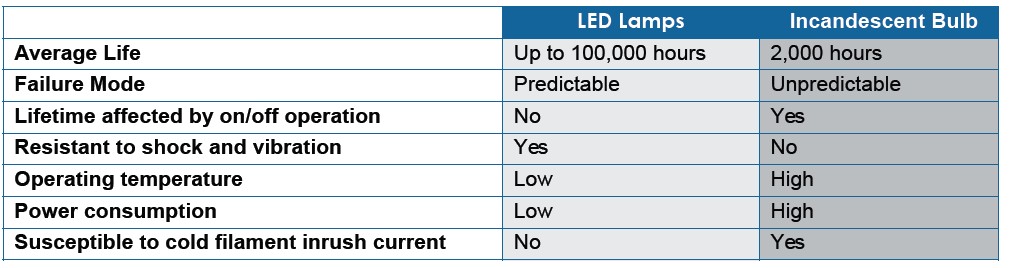

DDP Engineered LED Solutions outlines some of the advantages of solid-state LED technology for utility applications in a white paper published recently.

Overview

Since the early 1970’s, solid-state LED technology has offered a viable drop-in replacement for incandescent bulbs in visible indicator applications. The advantages that solid-state LEDs offer are particularly suitable for the utility industry where numerous lamps provide critical indication in control panels. Burned-out incandescent bulbs require continuous, costly maintenance and create safety concerns. But why then have only a limited number of utilities replaced incandescent indicators with LED lamps? This paper will show how wide-spread panel lamp replacement with LED technology provides a payback in less than 12-months. This paper also discusses the issues of reliability and safety for critical indication applications.

The primary benefit of LED technology is the tremendous cost savings for the user as a result of eliminating replacement cost, lowering power consumption, and reducing operating temperatures. Moreover, LED lamps improve efficiency by providing reliable status indication.

Power Consumption

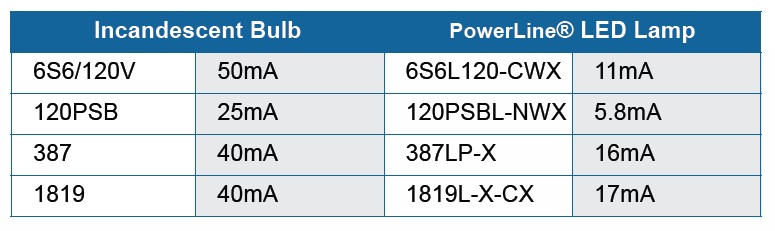

LEDs generally draw much lower current than incandescent bulbs. While lower power consumption reduces operating costs, it also reduces wear on other components in the application such as transformers, batteries and power converters.

Cold Filament Inrush

When cold, an incandescent filament draws ten times as much current as it does during normal operation. The initial powering of hundreds of incandescent bulbs simultaneously causes significant voltage surges that lead to lamp failures.

LED lamps, properly designed like those from DDP®, are designed with series resistors to limit the operating current, resulting in no cold filament current variation.

Predictable Life-10,000 Hours

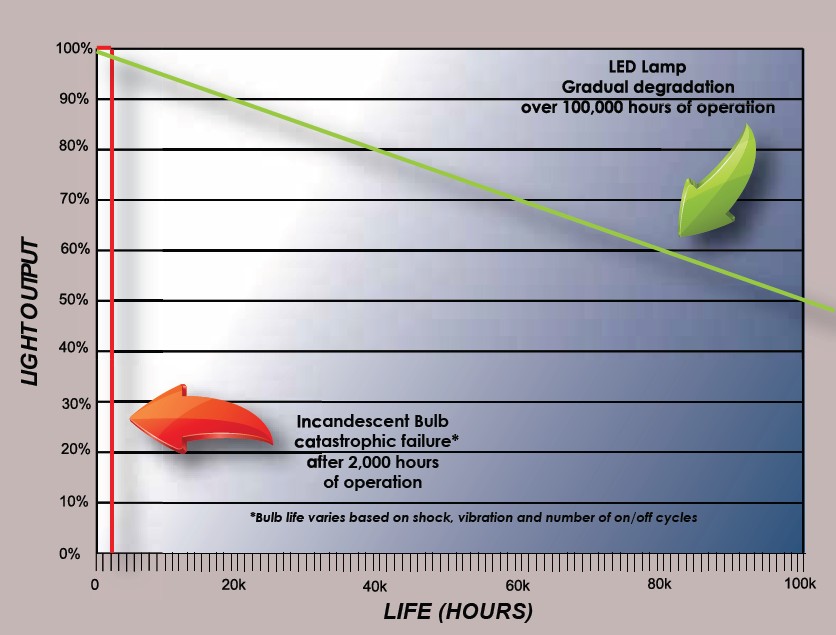

The most compelling advantage of using LED lamps over traditionally installed incandescent is the predictable life of LEDs. LEDs are solid-state devices and, by definition, control current without heated filaments. When used within its design parameters, an LED lamp will operate up to 100,000 hours (or 10 years). Furthermore, LED lifetime is not shortened by turning the lamp on and off.

The life of an incandescent bulb is unpredictable - subject to catastrophic failure due to shock, vibration, or cold filament inrush current. Initial powering of a control panel with numerous incandescent bulbs will generally result in several failures.

Shunt Resistor

Because noise current as low as .25mA may cause the LED to illuminate dimly in the off state, DDP® LEDs are designed with a built-in shunt resistor to bleed-off residual current. There are several sources of leakage current in a circuit. Transient voltage from a relay or discharge from a capacitor creates circuit noise. Also, inherent in the design of some programmable logic controllers (PLCs), is a triac protective circuit that may supply up to 5mA of leakage current in the off state.

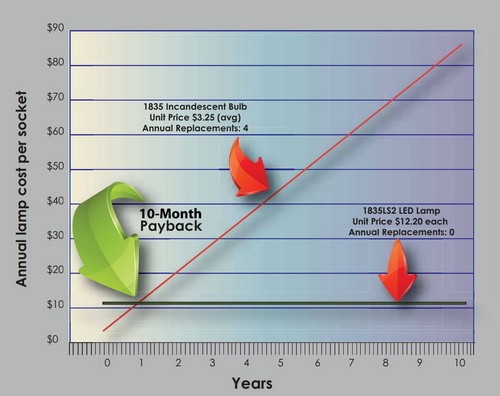

Cost Savings

Based on an average incandescent bulb life of three months, converting to LEDs will pay for itself in material costs alone within the first year. This payback period is only considering the cost of the incandescent bulb. It does not take into account the labor cost associated with changing bulbs, power savings, operating downtime, incandescent bulb inventory and ordering costs, and other significant factors. The following graph depicts the average cost of replacing a US$ 3.25 1835 incandescent bulb in one socket four times a year. The cost of a single 1835LS2 lamp is fixed at US$ 12.20 for 10 years.

For a facility with only 1,000 lamps, the material savings alone would be approximately US$ 3,000 after the first year.

Cooler Operating Temperatures

Since incandescent bulbs generate light by heating a filament, they also heat the lenses they illuminate. This causes discoloration and eventual melting of the control panel lenses. LED lamps generate much less heat than the incandescent bulbs they replace. Furthermore, heat is dissipated through the base of the LED lamp, keeping the lens cooler. With extended use of incandescent bulbs, where the indicator is 90% or more illuminated, lens melting and discoloration is common.