Philips Lumileds introduces LUXEON UV, a family of LEDs that delivers the very highest system flux densities. Available in wavelengths of

380-430nm, the emitters are specifically designed for applications including ultraviolet curing, counterfeit detection, medical, industrial and specialty lighting.

|

|

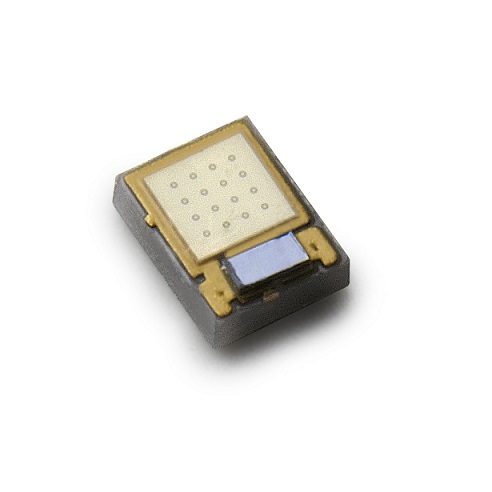

LUXEON UV LEDs are 1/5th the size of other high-power emitters (photo courtesy: Philips Lumileds) |

“The UV LED market has been hampered by limited flux density and a lack of design flexibility,” said Kurosh Hashemi, Senior Product Line Manager at Philips Lumileds. “Philips Lumileds addressed these limitations by introducing a compact, high-power emitter that can be tightly spaced to deliver the highest flux density to the desired medium. For example, for curing applications, 395nm emitters enable arrays of up to 38W/cm2 when driven at 1A.” With a micro-footprint of only 2.2mm2, each LED is provided in undomed form for precise optical control.

Since the product’s inception, Philips Lumileds has optimized LUXEON UV LEDs for high reliability: using surface mount assembly instead of wire bonding; designing for high-power operation (up to 1A drive currents) with best-in-class droop and forward voltage; and offering multiple binning options. The LUXEON UV is modeled after the company’s successful LUXEON Z family, winner of the Ultimate Product Award in the LEDs & Lighting category of the 2013 UBM ACE Awards. “We combined the proven advantages of high-flux density and optical control of the LUXEON Z design with a high-performing UV chip,” said Hashemi.

The LUXEON UV is designed for superior thermal management. The package utilizes flip chip assembly, where the chip is in direct contact with the thermally conductive AlN substrate. “Customers wanting to utilize air cooling units rather than more costly water cooling are very excited about the LUXEON UV offering,” said Hashemi.

LUXEON UV from different angles (photo courtesy: Philips Lumileds)