The LED industry market competition has intensified leading to price plunges, and even some LED lighting manufacturers releasing low priced products that have been given the “cabbage price” nickname, reported Chinese LED website Grand Lighting (Dazhaoming). Prices of international LED manufacturers mid to high range LED products remain high, creating a huge price difference.

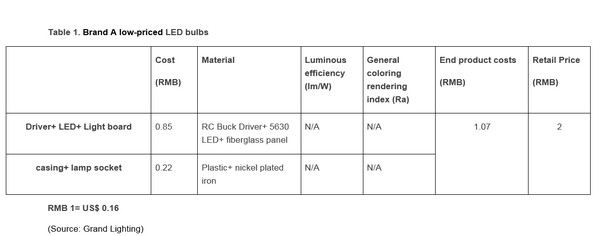

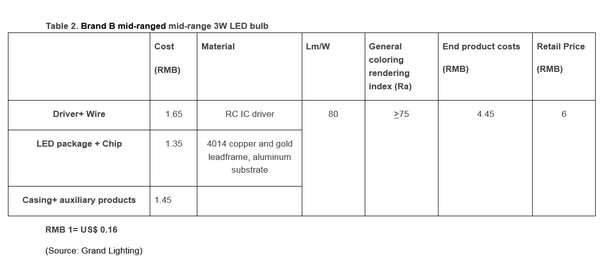

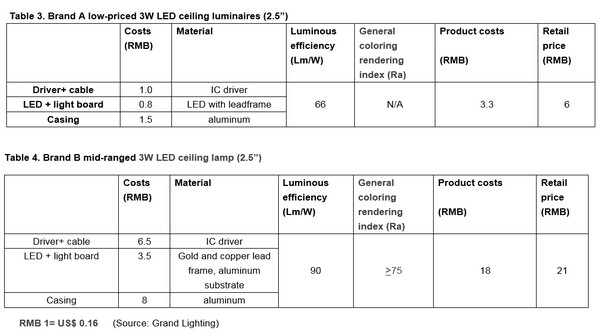

Why are there huge price differences between the same LED products? To analyze the price differences, Grand Lighting compared three products from a low priced brand against three products from a mid-range brand.

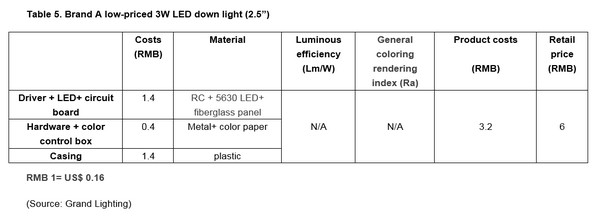

From the above table it can be observed that there are huge differences in brand A low-priced product and brand B mid-range product costs.

|

|

|

|

|

Brand A's low-priced 3W LED bulbs (top) and brand B's mid-ranged 3W LED bulb products (bottom). (All images courtesy of Grand Lighting)

|

Brand B’s mid-ranged 3W LED bulb price costs are about RMB 3.38 (US $0.55) higher than brand A’s low-priced products, and about RMB 4 higher than the average selling price (ASP) in China. Brand B’s material costs for different LED components are also several times higher than brand A.

|

|

|

|

|

Brand A's low priced 3W LED ceiling lights (top) versus brand B's mid-range 3W LED ceiling lights (bottom).

|

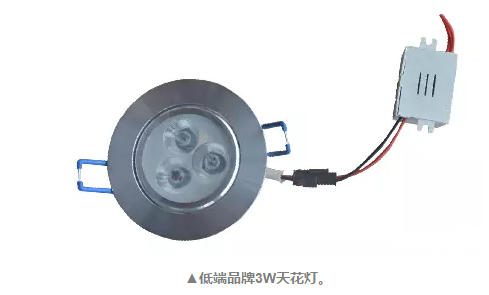

An inspection of 3W LED ceiling lights reveals brand B’s mid-range product costs is about 5.45 times that of brand A, with differences in retail price reaching RMB 15. In terms of material, the LEDs used by brand B are gold and copper wire, while the low-class brand A uses aluminum leadframe LED. The mid-range brand B LED components including driver plus cable, LED and light board, and casings cost respectively 6.5 times, 4.4 times, and 5.3 times that of brand A.

|

|

|

|

|

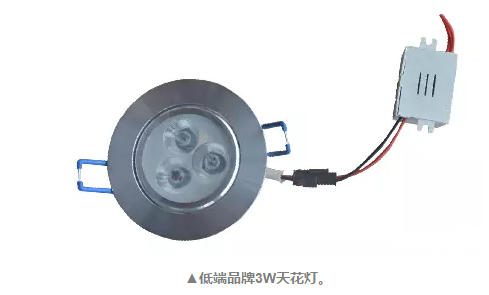

A comparison between the structure and designs of brand A's low priced LED downlight (top) and brand B's mid-ranged LED downlight (bottom).

|

A comparison of 3W LED ceiling lights reveals brand B’s costs is about RMB 14.8 higher than brand A ceiling lights RMB 3.2. Brand B’s mid-ranged products are also priced much higher than the average selling price of low-end products RMB 15. Moreover, aluminum casings used by brand B’ cost RMB 7.65, in contrast brand A’s plastic casings cost a mere RMB 1.4. Brand B’s power sources and LED material also cost several times that of brand A.

From the above comparison, it is not too hard for us to observe how low-priced LED products are manufactured. To acquire a better understanding of product prices, it is recommended that retailers disassemble LED luminaires and compare component costs.