|

|

|

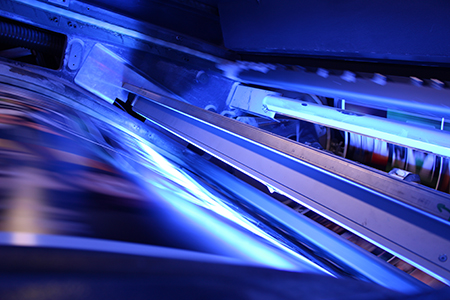

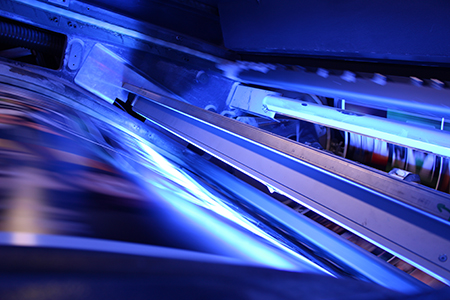

Energy-saving LED UV drying option (Photo Courtesy of Manroland Sheetfed)

|

The Energy-saving LED UV drying technology option supplied with the ROLAND 700 Evolution offers many benefits for printers, enabling more vibrant color and higher levels of productivity on a wide range of substrates, along with significant cost and environmental benefits and greatly increased viability for short-run printing. LED technology provides instant drying, on paper, synthetics or metalized stocks, and because it does away with the need for spray powder, it also offers significant environmental benefits.

LED power and control units are compact and energy efficient, needing only 50 - 70% of the power required by LEC-UV and 20% - 30% of the power required by typically UV equipment, while occupying a significantly smaller footprint. These are completely integrated into press functionality, and segmentation of power output delivers further savings. LED drying also does away with marking issues on the press and combines higher color brilliance with more sharpness, while doing away with the need for protective coatings. The ink dries instantly through exposure to the LED light so no further surface protection is required. Because the LED process generates light with no heat, presses can operate with low pile temperatures with no sheet curling or other registration issues.

Summing up the benefits of LED UV drying technology on the ROLAND Evolution, Manroland Head of R&D Stefan Finger commented:

“The advantages of LED technology for the ROLAND 700 Evolution are threefold; higher print quality than we could ever have believed possible along with significant energy reduction and instant post production processing to deliver significant efficiency benefits for our customers.”

LED technology can be specified on the majority of ROLAND sheetfed formats, either new or retrofitted. To find out more please contact your local Manroland office or email evolution@manrolandsheetfed.com