|

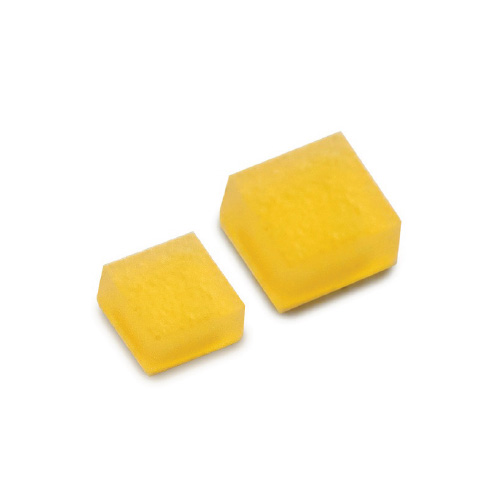

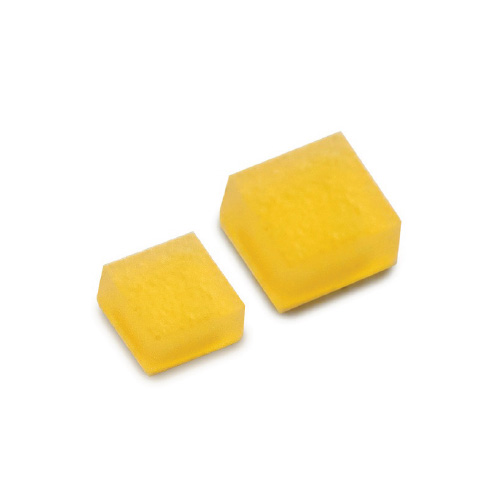

Lumileds' new CSP flip chip LEDs enables high packing density thanks to its small source size and high lumen density. (Lumileds/LEDinside)

|

Lumileds extends its CSP leadership, announcing LUXEON FlipChip White. Spearheading the adoption of CSP in LEDs, Lumileds has shipped over 500 million LED emitters to date across several applications. The company first introduced LUXEON FlipChip Royal Blue in February 2013, giving luminaire manufacturers complete design flexibility by starting with the LED die. In early 2015, Lumileds released the LUXEON FlipChip UV, and has now introduced LUXEON FlipChip White for the general illumination market. CSP technology eliminates the traditional submount to minimize package size, thus enabling manufacturers to directly attach the LED die to the PCB, allowing for overall system cost reductions. Lumileds CSP technology is optimized to deliver high efficacy at high current density, achieving industry-leading lumen density and lm/$.

High lumen applications such as outdoor and industrial lighting benefit from the high drive current capabilities and robust high power architecture of LUXEON FlipChip White. In addition, the small source size and high lumen density of LUXEON FlipChip White enables high packing density and superior beam control for directional lamps and luminaires. LUXEON FlipChip White is offered in two package sizes (1.4 x 1.4 mm and 1.1 x 1.1 mm) and a range of CCTs across 70 and 80 CRI.

Lumileds further accelerates the industry’s adoption of CSP Technology by offering LUXEON FlipChip White on its market-leading Matrix Platform. These LED boards, linear flex and modules can come configured with LUXEON FlipChip White along with connectors, optics, wiring and/or electronics, improving time-to-market and simplifying the supply chain.