(Author: Ivan Lin, Head of Content, LEDinside)

The market for automotive LED components has grown rapidly in recent years. In the interior automotive lighting application market, the penetration of LED products has reached 70% to 80%. The number of vehicles using LED headlamps has also increased considerably. Among Taiwan-based LED package suppliers, EVERLIGHT has been the most active in the automotive LED market. As one of the leading LED manufacturers worldwide, EVERLIGHT has overcome technology barriers to achieve mass production capability to provide a wide range of automotive LED products. In a recent interview with LEDinside, Torrent Chin, Associate Vice President, Product R&D Marketing, EVERLIGHT, discussed in detail the company’s developments in the automotive LED market and trends observed.

Securing emerging markets first before competing in mature markets in America and Europe

EVERLIGHT is simultaneously engaging in different global markets, Chin pointed out the rate of Return on Investment (ROI) varies across regions, due to the diverging market development pace in each area. To compete against leading international LED suppliers that have established themselves in the automotive lighting industry for many years, and have a distinct market advantage, EVERLIGHT’s current market strategy is working with car manufacturers in emerging markets, and collaborating with automotive lighting manufacturers in these markets to accelerate the rate of ROI. The Taiwanese company has prioritized emerging markets because product requirements in mature automotive lighting markets is more stringent forming higher entry barriers. Becoming part of the supply chain in developed markets, where existing automotive lighting suppliers and car brands have forged long term partnerships, therefore will be a long undertaking. On the other hand, testing and verification processes is shorter in emerging markets including China, India and Southeast Asian countries, so there is larger market opportunities in these countries.

For instance, China has about 22 major domestic car brands and their supply chains generate huge market demands for the local market. A major issue for LED companies tapping into China’s budding automotive lighting market is tailoring products to meet demands of diverse car models. In contrast, Europe and U.S. car manufacturers are pack leaders in the automotive market, but these regions stringent automotive regulations has resulted in a longer verification process that significantly delays the rate of ROI. EVERLIGHT’s ROI from its design-in projects for European and American car makers for example is not expected to be achieved till 2019.

|

|

EVERLIGHT's latest LED product lineup for exterior automotive lighting applications. (All photos courtesy of EVERLIGHT) |

Chin added that client verification processes for interior or exterior automotive LED applications all require a certain amount of time. Contrary to market rumors that electrical vehicle’s LED lighting testing period is shorter than regular vehicles, there is negligible difference between product test duration between the two vehicles. Taiwanese LED chip suppliers have found collaborating with automotive lighting manufacturers and Original Equipment Manufacturer (OEM) markets offer better prospects compared to the aftermarket. EVERLIGHT currently has its sights on both OEM and outsourcing markets in India, China and Southeast Asia. Japan, in particular, has allowed very few Taiwanese companies into their supply chains.

Design In solutions: working with partners to overcome challenges and develop key product features

Chin stressed that EVERLIGHT has closely collaborated with many car makers in the R&D of interior and exterior automotive LED products. To provide a total solution with Design In services, EVERLIGHT will work with their clients to quell the following challenges:

[1] Achieving goals and deadlines set by clients.

[2] Passing complicated product testing processes.

[3] Determining the testing demands, and evaluating additional testing costs from incorporating new technologies.

[4] Meeting automotive lighting’s guaranteed minimum operational lifetime requested by clients.

Compared to product testing procedures and speed in Europe and U.S., Chinese car makers have varying testing standards with some companies having stricter criteria. Each Chinese province also has different jurisdictions, which contributes to slightly different regulations across the country. Nonetheless, testing and verification periods there tend to be shorter. In Europe, each type of automotive lights – interior display lights, interior ambient lights, tail lights, daytime running lights, headlamps and others – have their own specification requirements.

Currently, LED products have high penetration in new cars, where about 70% to 80% of new vehicles are equipped with LED lights. The market is thus maturing and growing at a stable pace. At the same time, clients are raising their requirements and pushing the limits of product development. Safety and reliability remain the top concern among car makers. In the case of LED headlamps, a host of issues must be addressed, including sulfide resistance, material durability, waterproofing and operating under extreme temperatures.

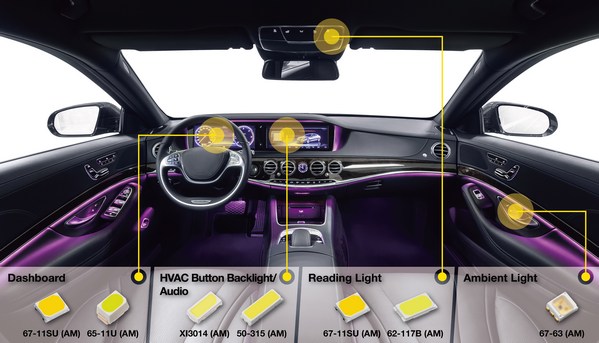

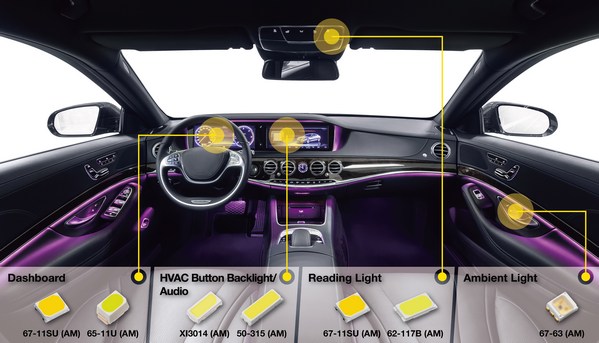

|

|

EVERLIGHT's interior automotive LED lighting products. |

EVERLIGHT’s competitive edge in the automotive LED market

According to LEDinside’s survey, EVERLIGHT has many advantages over smaller competing LED package manufacturers. These advantages include mass production reliability, better overall product design, stronger FAE and material management capacity. Chin also listed a few advantages that are unique to EVERLIGHT:

[1] Having the ability to provide optimized LED module solutions for automotive application. EVERLIGHT’s products and designs have all endured stringent tests.

[2] Being more knowledgeable than its competitors in many vital fields, including optics, mechanics, electronics and thermodynamics – this is the result of EVERLIGHT’s many years of experience in LED package manufacturing

[3] Being up-to-date with automotive lighting related standards and regulations.

[4] Equipped the necessary technologies and volume production capacity; EVERLIGHT therefore can make guarantees on its package technology, yield rate and product qualities.

The ability to maintain product quality is especially important when producing LED components in large volumes. EVERLIGHT’s production lines have continuously earned the industry’s recognition. Chin emphasized the average LED manufacturer currently does not possess the technical know-how to meet the requirements of designing and producing automotive LED packages. EVERLIGHT not only makes these products but also works according to the goals and deadlines set by car makers. To minimize risks, every step in the production (e.g. adding new materials, using new technologies) are broken down further, tested and verified before execution. Only an LED manufacturer that has reached a sophisticated level of technology can undertake this kind of complex manufacturing process, along with the additional testing activities. EVERLIGHT’s major advantage is therefore its ability to overcome these challenges.

Challenges from LD and OLED technologies in automotive lighting

European car makers have adopted laser diode (LD) for headlamps of vehicle models sold in the local markets. Meanwhile, OLED as an alternative light source to LED is also gaining traction in the automotive lighting market. Chin believes that the automotive lighting market is large enough to accommodate various technologies that can help car makers to differentiate themselves. As for automotive lighting manufacturers, they will choose LED or OLED depending on their respective needs.

However, LED’s unique strength is its compatibility with a wide range of designs. This opens up many possibilities for automotive lighting manufacturers. Also given the recent test results from the U.S. Insurance Institute of Highway Safety (IIHS), EVERLIGHT believes safety, reliability and the quality of the light source are paramount to a product’s market success. The company therefore has been committed to using advanced materials and technologies to build suitable LED packages that minimize glare and halo.

EVERLIGHT is deeply rooted in Taiwan and will continue to promote local R&D and production of mid-range and high-end products

EVERLIGHT believes the automotive LED market will enjoy significant growth in the future. Currently, automotive products accounts more than 10% of EVERLIGHT’s overall revenue. Their share in the company’s revenue is expected to grow 20% to 30% in the long run, which will be beneficial in bolstering the company’s future revenue and profits. Chin noted that EVERLIGHT’s advanced R&D efforts are carried out in Taiwan and the resulting high-quality LED products is widely recognized on the international market. From the long term perspective, EVERLIGHT’s automotive LED business will benefit Taiwan immeasurably and become a valuable part of the country’s huge automotive component chain.

In sum, EVERLIGHT strives to become the top supplier of high-end LED products to assist car makers worldwide in designing their respective fuel, hybrid and electric vehicles. At the same time, the company is committed to the advancement of Taiwan’s industries.