-

10% of design engineers are still relying purely on physical prototyping rather than a combination of prototyping and simulation

-

49% of engineers must produce multiple physical prototypes before completing their designs

-

10% of design engineers aren’t creating any prototypes before developing their products for launch

1 in 10 design engineers are still relying on purely physical prototypes, potentially adding significant, unnecessary costs to their designs. That’s according to new research from 6SigmaET, which surveyed over 350 engineers working in industrial, consumer and mass-produced electronics.

Rather than running simulations to test their products, the new research highlights that many engineers (49%) are having to produce multiple physical prototypes throughout the design process. This is adding significantly to the end production cost of electronics products, components and designs.

|

|

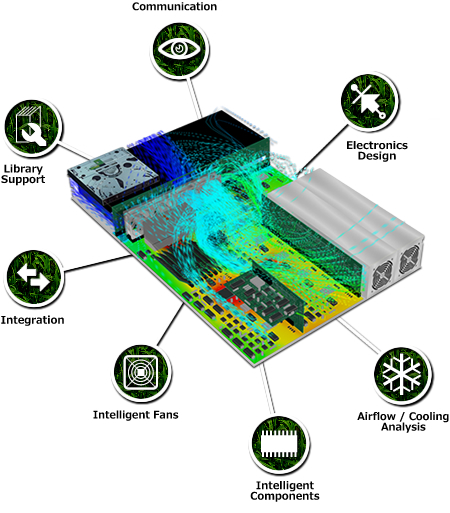

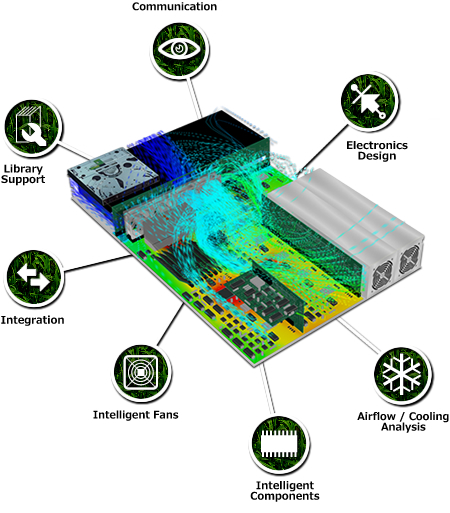

6SigmaET's server stimulator software product. (6SigmaET/LEDinside) |

Commenting on these findings, Tom Gregory, Product Manager at 6SigmaET said, “More than ever, manufacturers and design engineers are under pressure to keep the costs of their designs low. At the same time, end designs still need to be effective and cutting costs should never equate to cutting corners.

“Given the need to limit costs, I’m surprised to see just how many of today’s design engineers are only relying physical prototypes. Rather than incorporating software simulation for a right-first-time approach, engineers continue to produce multiple rounds of expensive prototypes for their products. This is not only bad design practice, but as those costs are passed down the line, it becomes bad news for manufacturers and, ultimately, the end consumer.”

Additional findings from 6SigmaET’s research highlight that 40% of design engineers use simulation to reduce the number of physical prototypes, while 10% rely purely on simulation and don’t produce any physical prototypes and aim for ‘right first time when designing their products. It is essential to properly validate the design before manufacture to avoid poor quality products, potential design issues such as overheating and interference, as well as costly “back to the drawing board” product recalls. According to independent data from WeMakeItSafer, in 2016 alone there have been 16 large scale recalls of electronics goods across the UK, including from brands such as Samsung, Whirlpool and Denon.

6SigmaET’s research can be viewed in full in the company’s new Heat is On report, available to download here: 6sigmaet.info/The-Heat-Is-On