Corning, a global leader in silicones, silicon-based technology and innovation, introduced Dow Corning CL-1000 Optical Silicone Binder, a new, more thermally stable, high refractive index (RI) material available only in China that is formulated to expand design options for high-power chip-scale

LED packaging (CSP). The latest addition to the company’s portfolio of advanced solutions for

LED lighting, CL-1000 Binder offers best-in-class thermal stability and is optimized for compression molding processes.

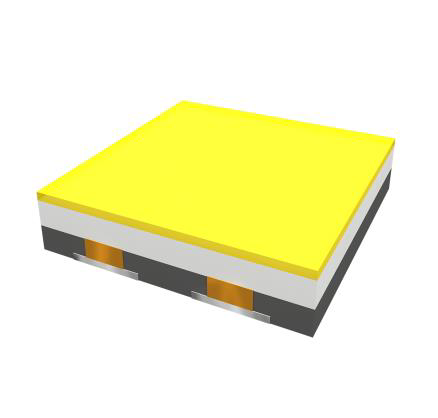

Dow Corning introduced Dow Corning® CL-1000 Optical Silicone Binder, a new, more heat-resistant, high refractive index (RI) material formulated to expand design options for high-power chip-scale LED packaging (CSP). The latest addition to the company’s portfolio of advanced solutions for LED lighting, CL-1000 Binder (shown here in yellow) offers best-in-class thermal stability and is optimized for compression molding processes.

Photo courtesy of Dow Corning, a wholly owned subsidiary of The Dow Chemical Company.

“The growing adoption of chip-scale packaging is enabling lighting designs that pack increasing numbers of LED dies more densely together in smaller form factors,” said Takuhiro Tsuchiya, global marketing manager at Dow Corning. “CL-1000 Optical Silicone Binder is Dow Corning’s response to the rapidly rising temperatures within these emerging applications. A more thermally stable iteration of our high-RI optical materials, this new product is formulated specifically to help enhance the robustness of high-power CSP designs.”

Validated through Dow Corning’s stringent testing, the superior thermal stability of CL-1000 Optical Silicone Binder enabled it to exhibit lower degradation and improved maintenance of mechanical properties vs. other high-RI silicone encapsulants after 2,000 hours exposure to temperatures above 180°C. The new high-RI material also delivers excellent photo-stability with high clarity to further support reliable performance over the life of LED devices.

New CL-1000 Binder demonstrates good conformance with highly reflective Dow Corning® WR-3001 and WR-3100 Die Edge Coat materials, enabling CSP packaging with enhanced reliability over longer periods. The product’s high Shore D60 hardness also enables LED packaging to withstand dicing operations.

CL-1000 Optical Silicone Binder leverages the same phenyl silicone chemistry as Dow Corning’s other industry-leading high RI optical encapsulants, which can help optimize the efficiency of next-generation LED lighting designs without costly investments in more powerful LED dies.

A market leader in materials, expertise and collaborative innovation for LED lighting concepts, Dow Corning offers solutions that span the entire LED value chain, adding reliability and efficiency for sealing, protecting, adhering, cooling and shaping light across all lighting applications.