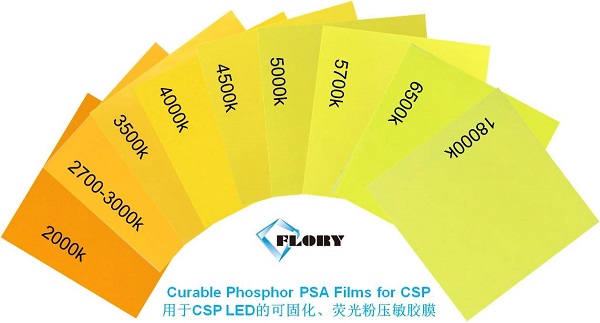

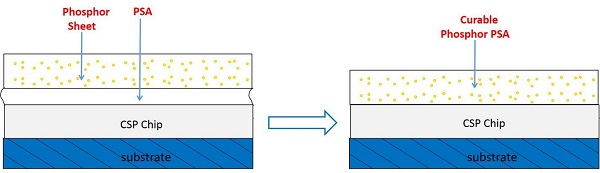

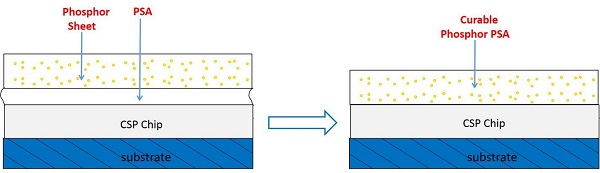

Curable Phosphor PSA Films designed for CSP LED high-volume manufacturing were successfully developed and mass-produced by FLORY Optoelectronic Materials Company in Suzhou of China after years of innovation and optimization. The pressure-sensitive nature of this Phosphor Film (PF) eliminates the usage of an extra-layer of PSA in between the phosphor sheet and the CSP chip (Figure 1). The use of Curable Phosphor PSA Films can significantly simplify the CSP packaging process, enhance reliability, improve yields and productivity, and reduce the cost of ownership. In addition, curable and thermally conductive silicone pastes T02-01 with excellent gap filling and high conductivity were successfully developed as well at FLORY Materials.

|

|

Figure 1. Curable Phosphor PSA Films designed for CSP LED HVM can simplify packaging process and reduce BOM and COO. (Image: FLORY)

|

CSP (Chip Scale Package) LEDs have been the frontier in LED innovation in the last few years. The profound advantages of CSP, just to name a few, include the smaller form factor, higher lumen output, better thermals and reliability, lower cost, and ease of integration. Currently, CSP LEDs enter into applications such as smartphone flash lights, ultra-thin TVs backlighting, and automotive lightings. Industry insiders noted that once Chinese companies fully control the frontend and backend markets, it can be foreseen that CSP LED volume will soar in the near future.

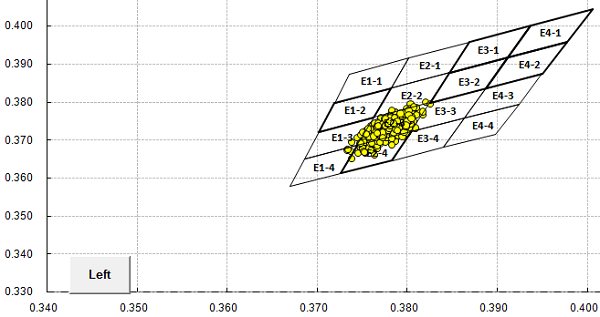

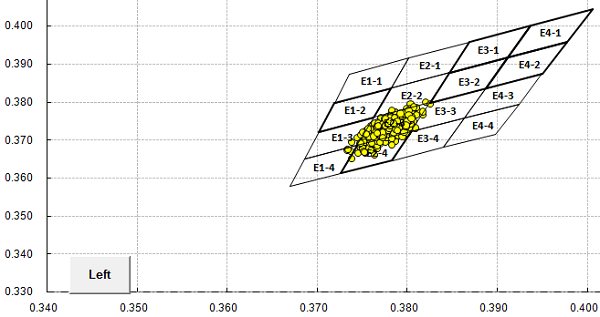

Phosphor sheets are a key raw material in CSP LED manufacturing. Due to the high density of phosphor, sedimentation of phosphor in the resin matrix can cause uneven distribution and significantly distort the uniformity of the sheet. The patented curable phosphor PSA innovated by FLORY Materials demonstrated excellent CIE x/y uniformity and binning results (Table 1 and Figures 1). The current offerings include PF1 and PF2 series, which employed normal refractive index silicone resins and high refractive index silicone resins, respectively. Excellent adhesion and thermal stability were also observed (Tables 2-3).

Table 1. Light color point consistency test results of CSP Curable Phosphor PSA PF1 products.

|

PF1 Film

|

CIE-x

|

CIE-y

|

Tc

|

Ra

|

|

average

|

standard deviation

|

average

|

standard deviation

|

|

PF1 #B84-15b

|

0.4199

|

0.0021

|

0.4064

|

0.0017

|

3326

|

84.7

|

|

PF1 #B84-55d

|

0.4230

|

0.0017

|

0.4101

|

0.0014

|

3297

|

84.2

|

|

PF1 #B84-85i

|

0.4245

|

0.0024

|

0.4113

|

0.0021

|

3278

|

84.3

|

|

|

Figure 2. The binning results of CSP Curable Phosphor PSA PF2 products.(Image: FLORY) |

Table 2. Excellent adhesion results demonstrated by PF1 products.

|

PF1 Film

|

Phosphor Content (wt%)

|

Adhesion(MPa)

|

|

240C24h

|

240C24h (cycling to rt every 2h)

|

260C24h

|

260C24h (cycling to rt every 2h)

|

|

PF1 #B92-115a

|

60.5%

|

>0.140

|

>0.140

|

>0.140

|

0.115

|

|

PF1 #B88-134m

|

33.3%

|

>0.140

|

>0.140

|

>0.140

|

>0.140

|

Table 3. Excellent thermal resistance demonstrated by PF1 products.

|

Condition

|

PF1 #B92-115a

|

PF1 #B88-134m

|

|

Tc

|

Ra

|

Tc

|

Ra

|

|

240C 0h

|

2796

|

82.9

|

5814

|

72.1

|

|

240C 48h

|

2786

|

82.9

|

5841

|

72.3

|

|

240C 96h

|

2808

|

82.9

|

5823

|

71.7

|

|

240C 144h

|

2818

|

82.9

|

5853

|

71.9

|

|

240C 207h

|

2821

|

82.9

|

5826

|

71.8

|

|

240C 332h

|

2838

|

83.0

|

5819

|

71.7

|

In conventional CSP LED processes, an extra layer of PSA is utilized in the mass production and sandwiched in between the phosphor sheet and the LED chips. The addition of this extra PSA layer may have a negative impact, not only on the light output and light quality, but also on reliability. The major advantages of the Curable Phosphor PSA technology include: 1) higher light lumen output; 2) simplified process and higher productivity; 3) reduced BOM and lower COO, more environmental friendly.

The Curable Phosphor PSA offerings from FLORY Materials have high hardness (Shore D60) and full spectrum coverage (2000K、2700K、3000K、3500K、4000K、4500K、5000K、5700K、6500K) and backlighting. Tailor-made products are offered as well in order to meet customers' special needs. The Curable Phosphor PSA can also be used in Remote Phosphor Applications. What's more, the Curable Phosphor PSA can be stored, shipped, and operated at room temperature, unlike the refrigerated conditions from other phosphor film vendors.

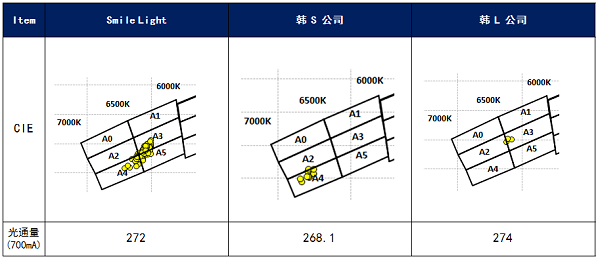

Among the fierce competition in the CSP LED market, KUNSHAN SMILE Light Electronic Co. quickly emerges as one of the technology leader and showed off innovative technologies and products with enhanced quality. The current offerings include automobile lighting CSP, flash CSP, backlighting CSP, and dual-tone COB CSP. KUNSHAN SMILE has been working closely with FLORY Materials and quickly adopted the Curable Phosphor PSA in its production. By eliminating the conventional PSA layer, KUNSHAN SMILE is able to improve the light lumen output by six to ten percent and is swiftly catching up to the top tier CSP vendors. Comparison data with International Leaders on light lumen output are shown in Table 4.

Table 4. Light lumen output comparison among 1919 CSP Products.

Currently, FOM offers a variety of differentiated Si-based LED packaging materials, which include: 1) A05 products for COB; 2) Phosphor Precipitation Encapsulant A06 and H30 products; 3) phenyl silicone encapsulant H20 products for SMD; 4) Aqueous sulfur-corrosion resistant (anti-sulfidation) coating C16 products; 5) UV adhesives E02 with ultra low dielectric constant. More information can be found at:

-

FLORY Optoelectronic Materials Company

-

website: http://www.florymaterials.com ;Phone:+86-512-62891767

-

e-mail: support@florymaterials.com ;2694661061@qq.com

-

KUNSHAN SMILE Light Electronic Co., Ltd

-

website: http://www.smilelight.cn;Phone:+86-151-62632551

-

e-mail: dslgt@smilelight.cn