Veeco Instruments completed a strategic initiative with ALLOS Semiconductors (ALLOS) to demonstrate 200mm GaN-on-Si wafers for Blue/Green microLED production. Veeco teamed up with ALLOS to transfer their proprietary epitaxy technology onto the Propel SingleWafer MOCVD System to enable micro-LED production on existing silicon production lines.

|

|

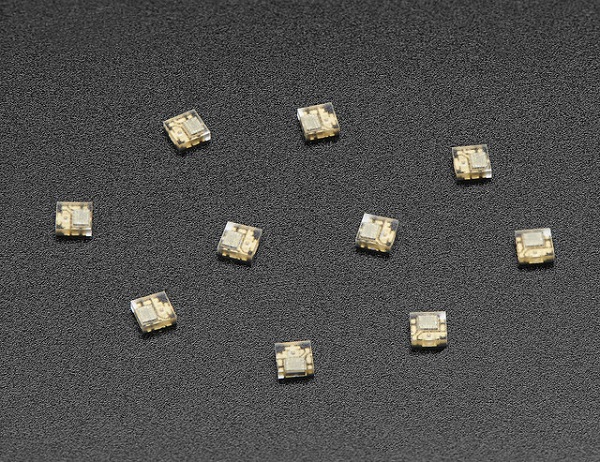

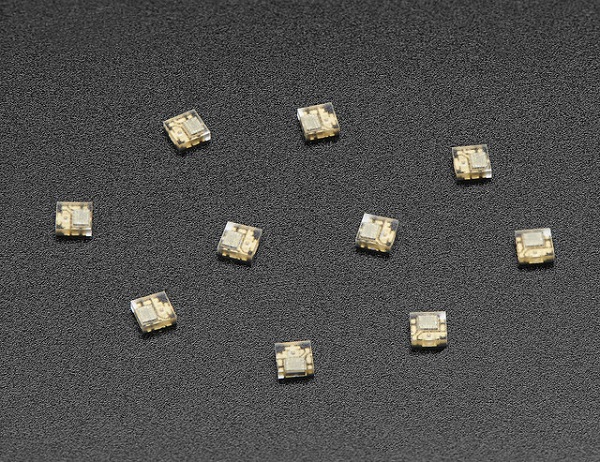

(Image: Micro LED Adafruit Industries via Flickr CC2.0) |

“With the Propel reactor, we have an MOCVD technology that is capable of high yielding GaN Epitaxy that meets all the requirements for processing micro-LED devices in 200 millimeter silicon production lines,” said Burkhard Slischka, CEO of ALLOS Semiconductors. “Within one month we established our technology on Propel and have achieved crack-free, meltback-free wafers with less than 30 micrometers bow, high crystal quality, superior thickness uniformity and wavelength uniformity of less than one nanometer. Together with Veeco, ALLOS is looking forward to making this technology more widely available to the micro-LED ecosystem.”

Micro-LED display technology consists of <30x30 square micron red, green, blue (RGB) inorganic LEDs that are transferred to the display backplane to form sub-pixels. Direct emission from these high efficiency LEDs offers lower power consumption compared with OLED and LCD while providing superior brightness and contrast for mobile displays, TV and wearables. The manufacturing of micro-LEDs requires high quality, uniform epitaxial wafers to meet the display yield and cost targets.

“In contrast to competing MOCVD platforms, Propel offers leading-edge uniformity and simultaneously achieves excellent film quality as a result of the wide process window afforded by Veeco’s TurboDisc technology,” said Peo Hansson, Ph.D., Senior Vice President and General Manager of Veeco MOCVD Operations. “Combining Veeco’s leading MOCVD expertise with ALLOS’ GaN-on-Silicon epi-wafer technology enables our customers to develop micro-LEDs cost effectively for new applications in new markets.”