There are many recent articles explaining mini LED or Micro LED. Some are correct, but some are not. Let LEDinside explain and tell you the differences between fine-pitch LED, mini LED and micro LED.

|

|

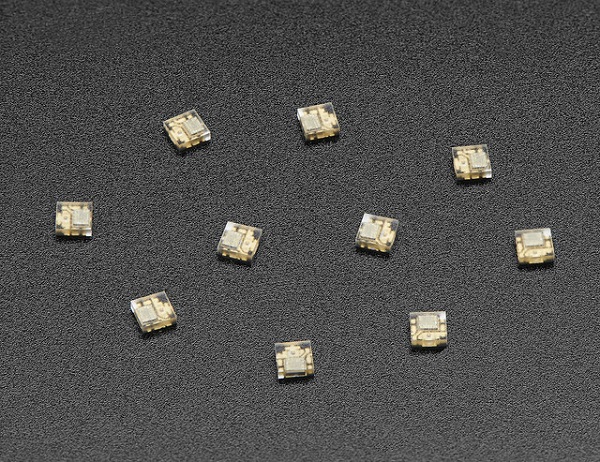

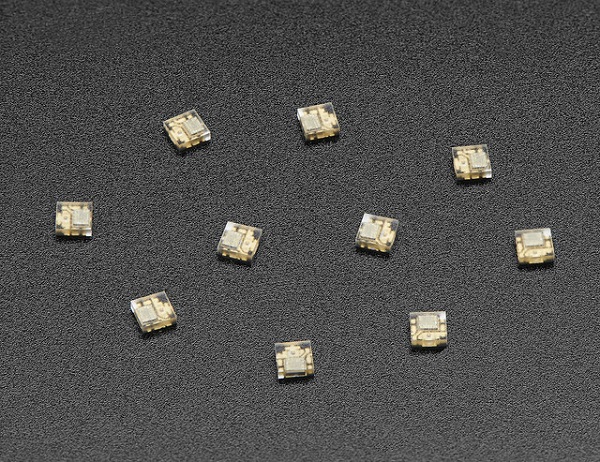

((Image: Micro LED Adafruit Industries via Flickr CC2.0) |

For example, is Samsung's LED cinema screen a mini LED or a micro LED? The answer is neither. Why?

Fine-pitch LED displays: Samsung LED cinema screen & SONY CLEDIS

According to Samsung's public statement, Samsung's LED cinema screen, approximately 455 inches, is 10.24 meters wide and 5.4 meters high. This screen provides 4K resolution and features 4,096 x 2,160 pixels. HDR imaging is available, and the brightness is about 500cd/m2.

According to LEDinside's calculation, this LED cinema screen's pixel pitch is 2.5 mm, and it uses 1010 packaged LEDs, the mainstream package size for fine-pitch displays. In the LED industry, technologies to make displays with such specification are very mature. Leyard is the leading enterprise in this segment.

Among Micro LED's difficulties, mass transfer is the most talked-about one. However, we should not overlook another major challenge- to form an interdisciplinary platform to integrate three industries into a supply chain. This difficulty is no less urgent than that of mass transfer.

What is the relation between fine pitch and micro LED? Sony's path explains it well.

From the previous CLEDIS TV to outdoor large display, this has been the road from micro LED to fine pitch. Sony experienced how hard it is to commercialize micro LED, so Sony chose to develop fine pitch LED which is slightly larger than micro LED. In this way, Sony's CLEDIS technology is in fact the fine pitch display technology. This LED display features a pixel pitch of 1.2mm. There are many fine-pitch LED companies manufacturing products with this specification.

Mini LED in backlight market

According to TrendForce’s reports on trends in technology industry of 2018, mini LED technology can work with flexible backplanes, and achieve curved backlight modules. Mini LED can be used for smartphone, TV, automotive display, and gaming NB. Mini LED based backlight samples are predicted to emerge in 2018.

Mini LED backlight is designed to enable local dimming. This feature leads to finer HDR local dimming zones. LCD's HDR local dimming scales and greater details actually come from brightness and related features of backlight modules.

Mini LED replaced edge-type backlight's dozens of high luminance LEDs with tens of thousands of direct-type mini LED units. Its level of "HDR" fineness sets a new record. Even though Mini LED unit is yet to be able to local dim pixel by pixel like OLED can, at least it can meet the extreme requirements to process local dimming signals for HDR imaging. In addition, LCD panels with Mini LED backlights tend to provide better CRI and can be manufactured as thin as an OLED panel.

Take a TV panel as an example. Before using mini LED, edge-type backlight only needs dozens of high luminance LEDs. Smartphone backlight merely requires 25 LED units. After applying mini LED, TV panel backlight set contains as many as tens of thousands of mini LED units. A 5-inch level smartphone panel could employ an amount of mini LED backlight up to 9,000 to 10,000 units.

As for the LED display segment, the number of RGB LEDs manufactured for displays each month amounts to 10~20 billion units globally.

In other words, if Samsung's LED display and Sony's CLEDIS become the new trends, there will also be great market potential for Mini LED in the outdoor large display segment. What about opportunities in automotive display and gaming laptop segments? Definitely a lot more than that.

With existing LCD technology and mature RGB LED technology, panel makers can develop next generation panels with mini LED backlights. In terms of power saving, image quality, thickness, costs, form factor, or the feature of being curved, mini LED can compete with AMOLED. To sum up, in many areas, there are great business opportunities for mini LED.

Micro LED smaller, finer yet so much harder

According to LEDinside’s research in 2017, it is pointed out that there is big market potential for the micro LED. If micro LED technology comprehensively replaces some of LCD display's components, the market scale of micro LED can reach USD 30 ~ 40 billion. For the entire market outlook, micro LED is indeed better but difficult. Why?

There are currently many hardships for "micro LED". First, the mass transfer technology is hard to commercialize. Thus, some companies chose "mini LED" which performs less than micro LED does. They hope that mini LED can serve as a transitional product before micro LED is fully ready. Some companies use mini LED to buy some time to develop micro LED's technology.

How long can mini LED continue to grab market attention? It, of course, depends on when micro LED is commercially ready. It must be massively transferred, yet is harder to repair. Also, the color should be consistent.

LEDinside believes that it will take years before micro LED is commercially ready. Meanwhile, micro LED is worthy of waiting because micro LED is in fact excellent in the following two ways:

First, there is an issue with both tradition LCD and AMOLED that they are hardly readable in the sun. Micro LED can improve it or even solve it. Second, micro LED's power saving feature is necessary because battery technology also reaches its limit.