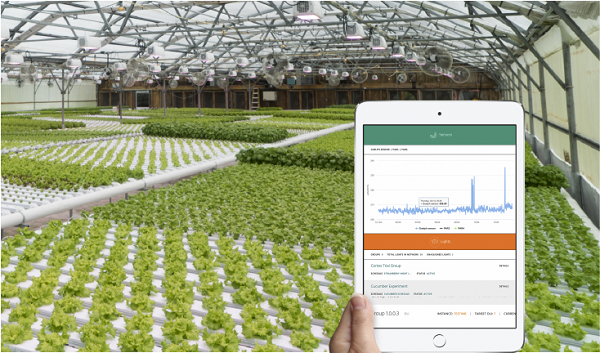

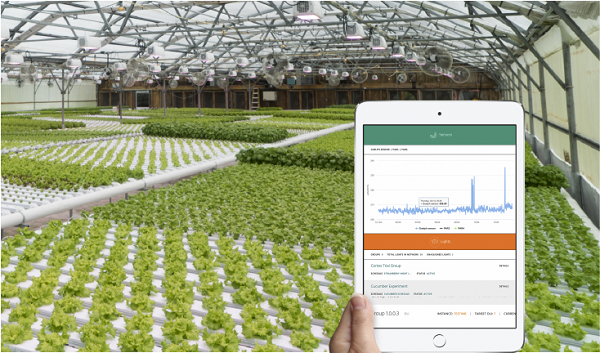

Heliospectra AB, specializing in intelligent lighting technology for greenhouse and controlled plant growth environments, announces the commercial release of the company's new light control software HelioCORE™. HelioCORE enables businesses to automate and connect growing environments in order to reliably monitor and forecast yields, and ensure consistent, high-quality crops year-round. Compatible with Heliospectra's LX60 and RX30 intelligent LED lighting solutions, the HelioCORE system is now available for order.

|

|

(Image: Heliospectra AB) |

The new HelioCORE light control software which was first introduced in July 2017, gives growers control of their growing environment and operational costs. With real-time management and remote notifications from any device, growers are able to monitor hardware status across their facilities and quickly control light settings, intensities, and spectrum strategies. Historical lighting strategies and instance isolations equip growers to make data-driven decisions for predictable, reliable, and repeatable business forecasting and harvest results.

"Processing big data is speeding up the artificial intelligence (AI) development in Horticulture. HelioCore is our AI platform helping our growers with making decisions in a more informed way. As part of company's vision, we will continue to build on this platform enabling growers to improve the quality of their crops, reducing production cycle, and making accurate predictions on yield," said Ali Ahmadian, CEO Heliospectra AB.

For any commercial size operation knowing and predicting the exact yield is key for success. Accurate forecasting plays a critical role in operations from price negotiations to buyer relationships and labor management. HelioCORE brings a unique solution to the market by combining industry-leading light control with automated response so growers see faster time to market and tighter inventory control.

"With HelioCORE, growers are delivered actionable, data-driven insights and are able to automate and gain control over every single parameter of their lighting. This has a huge impact on growers' revenue cycle and business performance," said Peter Nyberg, CTO Heliospectra AB.

During 2018, the HelioCORE control software was field- tested and verified by leading commercial growers and research institutions around the world. One of them is the John Innes Centre, an esteemed plant science institution in the United Kingdom. Known for having demonstrated the ability to accelerate harvest cycles for food staple crops, the research facility is using the HelioCORE On Target Controller in their speed breeding project. Research teams at John Innes grew wheat from seed to seed generation in just 8 weeks—57 percent faster— as part of a glasshouse wheat speed breeding project using Heliospectra's adjustable LED lighting solutions. Further, they are also testing the Schedule Controller for ongoing research trials.

Dr Brande Wulff, who leads the speed breeding research in the John Innes Centre, Norwich, states: "Many aspect of plant research are limited by the time it takes to go from seed to seed, or to obtain adult plants for measuring certain traits, such as plant height or flowering time. Our speed breeding program with LED lights allows us to obtain results twice as fast, and reduces operation costs. HelioCORE will help us to push those boundaries and give us more reproducible data and control of our environment"

Greenbelt Microgreens of Ontario, Canada also implemented the HelioCORE control system in a large-scale food production greenhouse during the seasonal low light winter months to ensure that the specialty microgreens the business delivers to retailers and restaurants across Canada received the constant and consistent light intensity needed for highest-quality crops, flavor, and taste.

"We want to use supplemental light and energy in the most efficient and cost-effective manner possible, while also maintaining summer season crop yields and product quality with optimal light levels," said Ian Adamson, founder and CEO of Greenbelt Microgreens.

The HelioCORE system dynamically adjusts light output based on natural light conditions and energy prices to ensure businesses use only the energy and supplemental light required to minimize costs.

HelioCORE™ Light Control Modules

Enabling growers to accurately forecast yields and harvest cycles, HelioCORE includes three control modules so growers and operations teams can easily customize lighting strategies, build and replicate light schedules, and integrate real-time sensor data with lighting controls to ensure that plants receive the precise, and consistent daily light requirements needed across all stages of growth.

-

DLI Controller – Regulates supplemental light using algorithms and Daily Light Integral (DLI) targets, to optimize light use while supporting optimal plant growth and prioritizing lamp use at times of day when energy and utility costs are lowest.

-

On Target Controller - Establish constant Photosynthetic Photon Flux Density (PPFD) levels to maximize plant efficiency, and photosynthesis, while keeping your energy consumption at a minimum, with dynamic response to seasonal changes in weather and natural light

-

Schedule Controller – Allow growers to apply customized lighting strategies and automate calendar schedules across production and harvest cycles. A library of pre-set schedules and sequence templates can be used to accelerate flowering, boost nutritional or medicinal profiles, and extend the photoperiod for food and long-day flower crops.