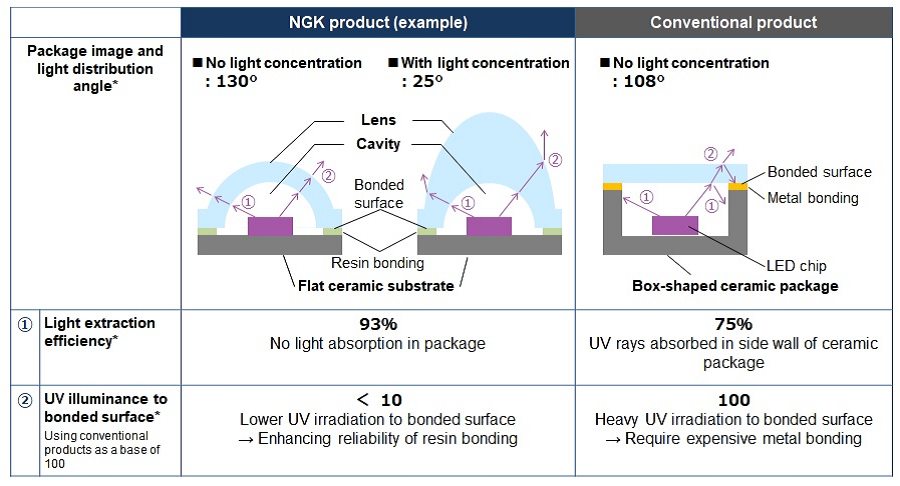

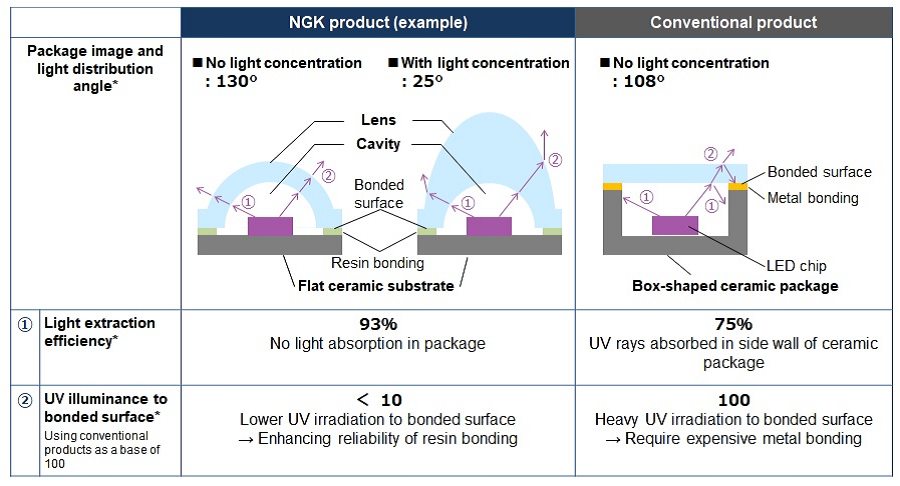

Japan-based NGK Insulators has developed a quartz glass Micro-lens equipped with a cavity to arrange UV LED chip.

NGK’s proprietary technologies make it possible to create cavities in any shape, such as a dome. This reduces UV irradiation in the bonded surface between the ceramic substrate and Micro-lens.

(Image: NGK)

Currently, Micro-lenses are bonded to the box-shaped ceramic package with high-priced metal that is resistant to UV rays to ensure reliability, but using NGK’s Micro-lens for UV LEDs raises the reliability of cheaper resin bonding, making resin bonding feasible and further reducing costs. Moreover, since lenses and not just cavities can be made with a high degree of precision in response to requirements, combining various lenses and cavity shapes creates more efficient light extraction and enables control of light distribution angle, which contributes to greater performance in devices equipped with UV LEDs.

(Image: NGK)