Macroblock launched the concept of “NEW BASICS” in March. Until now, we have received a lot of feedbacks worldwide. New BASICS consists of “Image Quality,” “Minimum Gray,” “HDR-Optimized,” “64 scans,” “Low power,” and “Highly-integrated.” Some elements of NEW BASICS are brand new to the industry. Thus, Macroblock would like to take the opportunity to share the updated experimental data and technology through LIVE streaming on June 17th.

In the opening, Macroblock's Deputy Director of the Sales Department, Sandra Tseng talked about the LED industry trends, including the rising demand "Drive-in Theater" and LED display makers launching sub-1mm 8K resolution displays continuously. These two applications reflect a fact that the whole industry is innovative to react to COVID-19 influence and is poised to replace LCD as the mainstream display for the indoor applications.

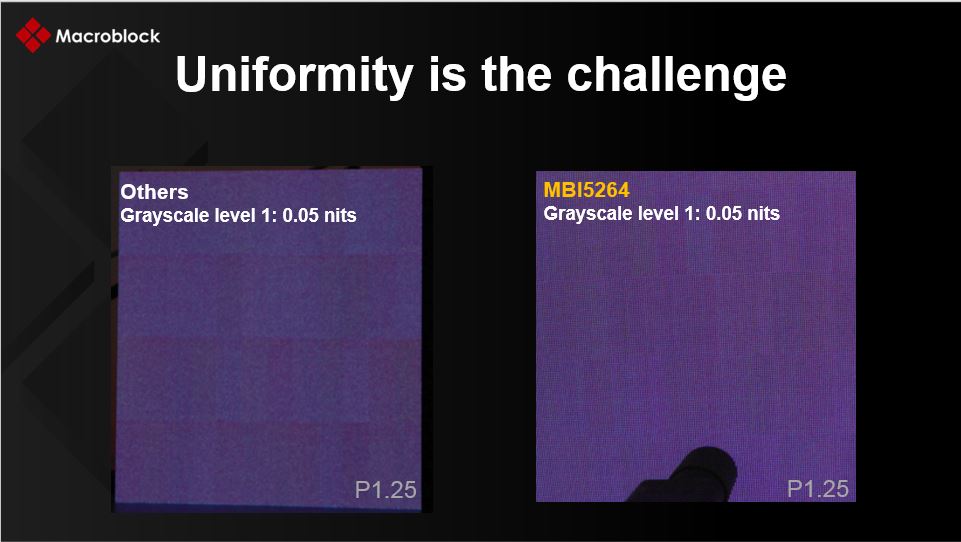

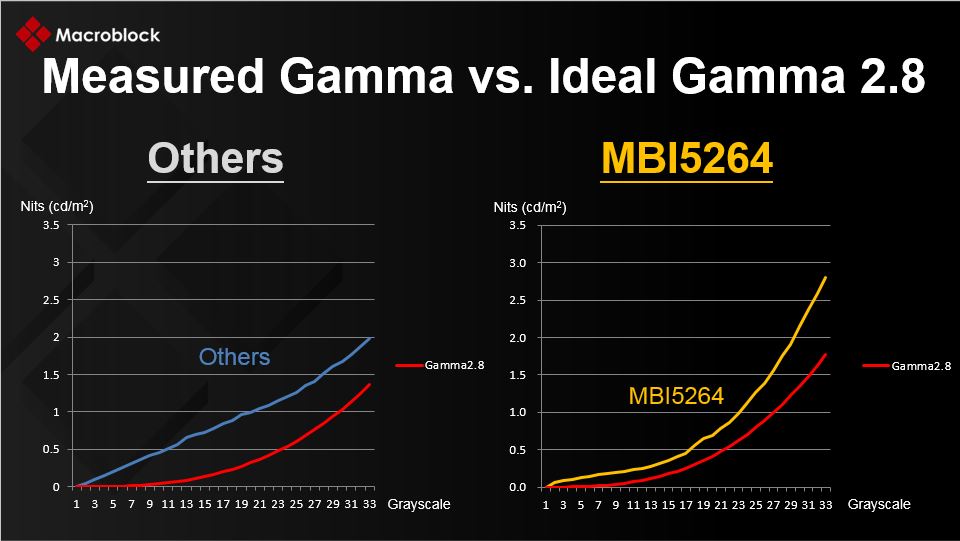

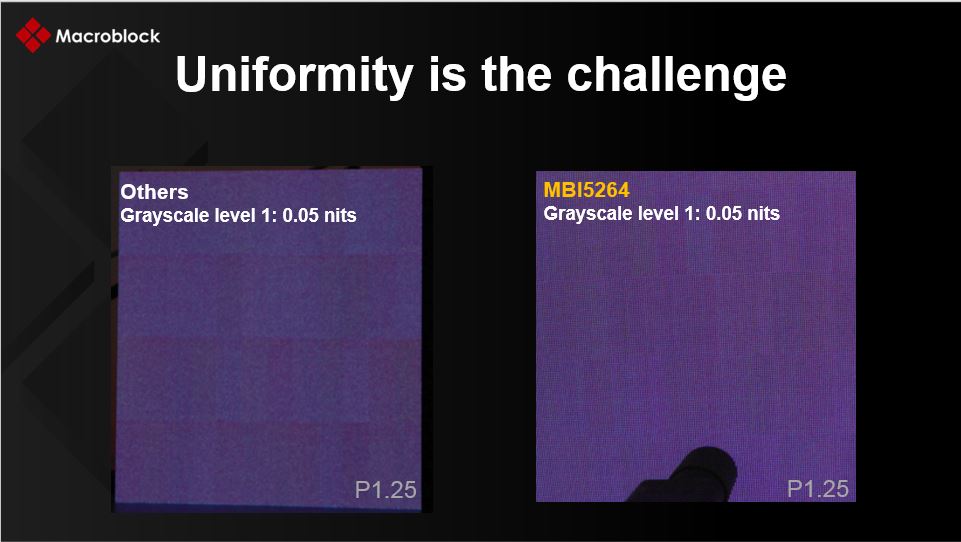

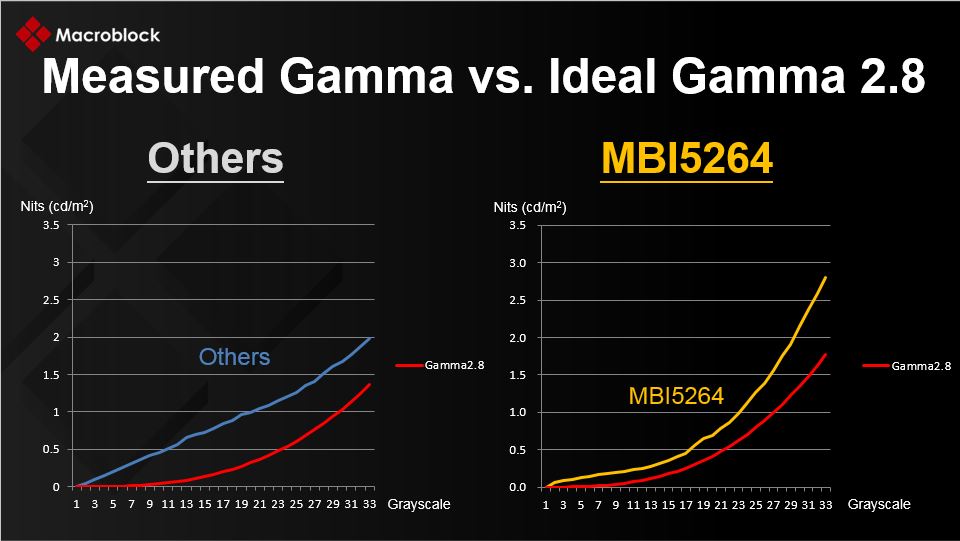

After the opening, the technology sharing session was leading by Technology Support Team Manager, Raymond Chang, and Business Development Manager, Albert Yang with witty dialogues. First, they focused on the visual performance elements of NEW BASICS, and they are “Image Quality,” “Minimum Gray,” and “HDR-Optimized.” For the past few years, Macroblock advocated the concept of “seven challenges” to standardize image quality. While "Minimum Gray" is debuted this year to emphasize the importance of the low grayscale performance of LED displays. That is because we find that visual performance at low brightness is critical to image quality, especially for indoor applications. Therefore, if end-users want to evaluate the visual performance of two LED displays, they should observe if there is a non-uniformity problem at the same brightness. Also, if the measured gamma curve of the display is closer to the ideal gamma 2.8, it means that this display can have a better image quality. During this session, Raymond compared the MBI5264 cabinet with others to explain “Minimum Gray.”

Figure 1. The uniformity of the MBI5264 cabinet is better than others’ solution while being at the same brightness 0.05nit.

Figure 2. The measured gamma curve of the MBI5264 cabinet is closer to gamma 2.8 than others’.

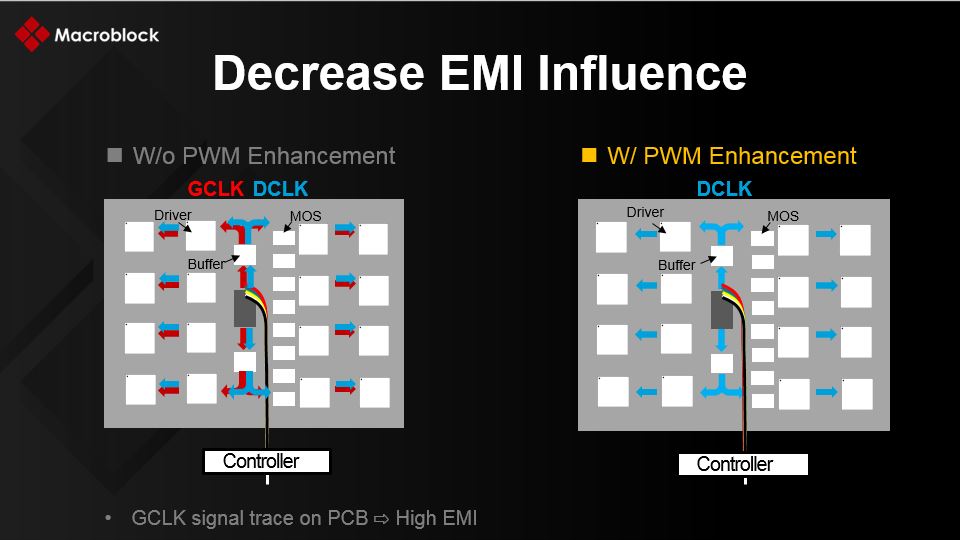

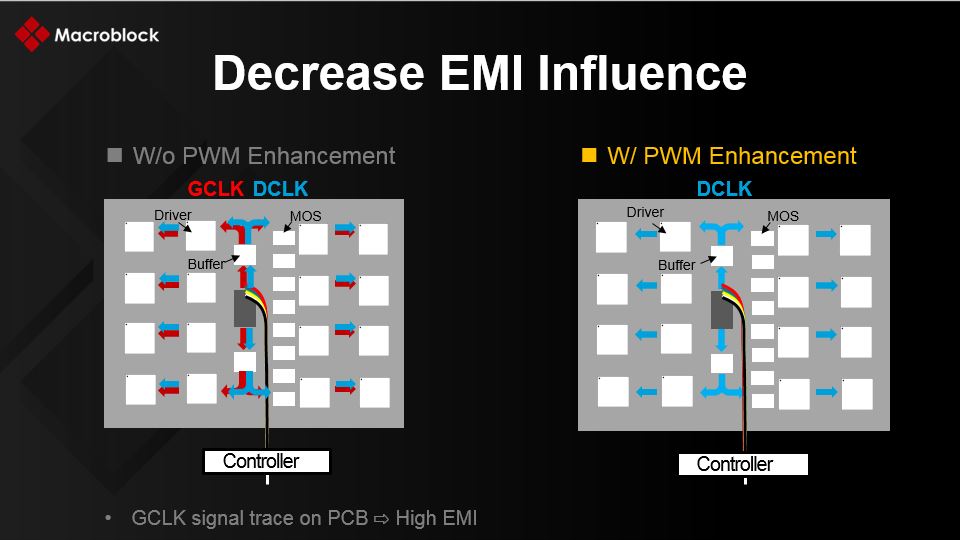

When it came to HDR discussion, Albert asked, “we know that only a few driver ICs can achieve 16-bit grayscale and 4KHz refresh rate at the same time, and what is the technology embedded of those ICs?" Raymond answered," MBI5359, MBI5850, MBI5264, and MBI5864 can achieve this high-performance standard, and those driver ICs have "PWM Enhancement" function." The PWM Enhancement function breaks the GCLK frequency limitation and makes LED display perform HDR-optimized visual effect; besides, there is no external GCLK signal on the PCB board, which is pivotal to reduce EMI influence.

Followed by three image quality elements, speakers talked about the "64 Scans." In response to the trend of ultra-fine pitch LED displays, it is inevitable to adopt high-scan LED driver ICs. The benefits of using high-scan drivers include 1. reduce the driver IC quantity; 2. make room for PCB layout; 3. No higher power consumption (experimental data) by the driver IC’s low IDD. Finally, Albert shared the 64-scan driver IC selection guide for Live participants.

Figure 3. No external GCLK signal on the PCB board is pivotal to decrease EMI influence.

The focus of the second session is Mini/Micro LED topics that are all the rage of the LED display industry. Through the conversation between Technology Support Team Deputy Manager, Hugo Chu, and US Regional Sales Manager, Anson Lin, audiences could understand the technology innovation and development of Mini/Micro LED applications easily and efficiently.

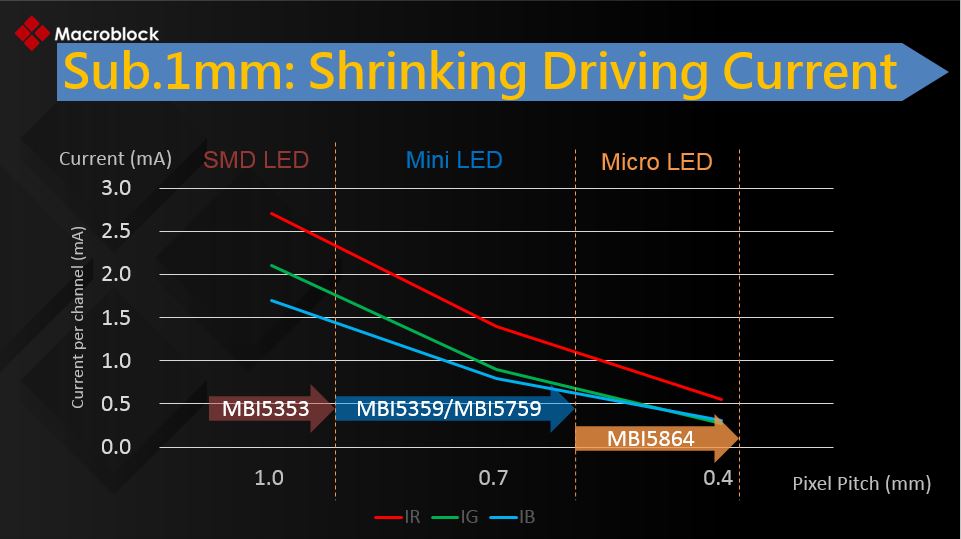

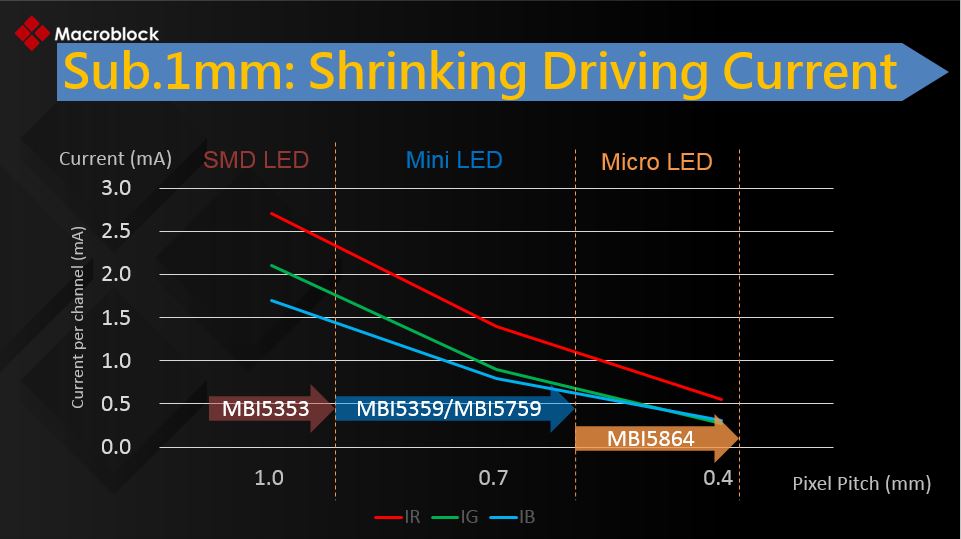

“For the sub-1mm LED module design, designers should consider using driver ICs which support not only high scans but also highly-integrated.” Hugo highlighted in his opening. Anson asked a further question, “we know that using highly-integrated driver ICs could solve the problem of insufficient space of PCB boards. However, what are other challenges for LED driver ICs for sub-1mm LED module designs?” Anson's question indicated that LED driver IC must shrink the driving current for sub-1mm applications. For the pixel pitch 0.4mm micro-LED applications, MBI5864's minimum driving current is 100μA that is the highest specification in the LED display industry. Macroblock has already had an MBI5864’s testimonial for a pixel pitch 0.39mm design.

Figure 4. The trend of shrinking driving current for sub-1mm applications

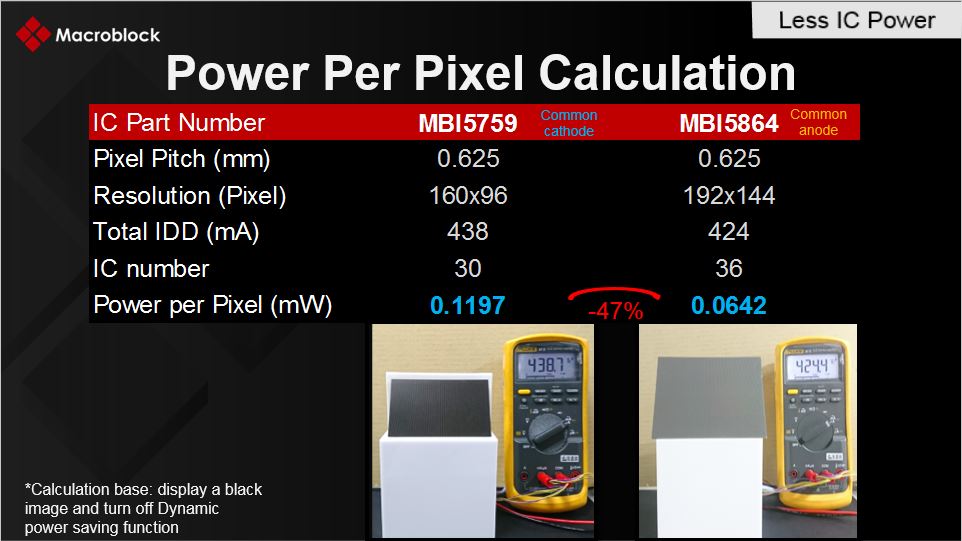

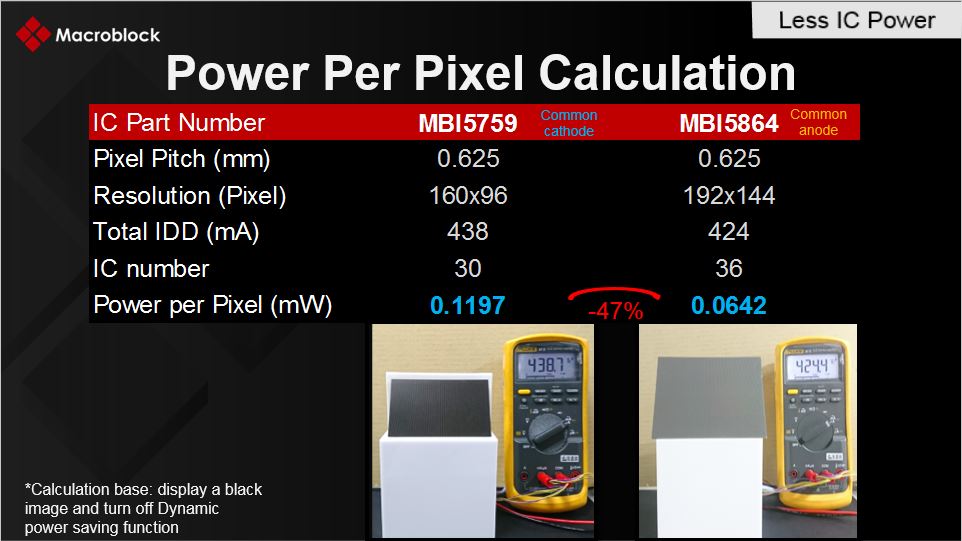

The sixth element of New BASICS, “Low Power” is the key to elevate user experience. Hugo mentioned there are three energy-saving methods, including “common-cathode LED display,” “IC’s Dynamic+ Power Saving Function,” and “IC’s Low IDD.” According to the experimental result, Hugo clarified that using a common-cathode solution is not the only way to decrease power consumption. When comparing modules' power per pixel between MBI5864 (common-anode) and MBI5759 (common-cathode), MBI5864's is lower by 47%. Also, the temperature difference of the “LED chip side” and “the backplane side (with driver ICs)" is quite low when using MBI5864. That means using MBI5864 does not lead to a higher temperature of the LED module and could decrease the possibility to result in "cyan blocks" visual problems. It is also beneficial to extend the LED display's life span at the same time. The aforementioned driver's features will bring the advantages to LED displays to replace LCDs as the indoor mainstream solutions. Moreover, the six elements of NEW BASICS have been recognized by Macroblock’s long-term partner, ROE, and we team up together to accelerate the high-end display development.

Figure 5. MBI5864’s (common anode) power per pixel is lower than MBI5759’s (common-cathode).