Currently, under the background of carbon peak and carbon neutrality policies, the whole industry is committed to actively realizing energy saving and consumption reduction of products with low cost and high efficiency by means of scientific and technological innovation. As a global industry leader in the field of LED display driver chip, Chipone’s R&D team has been deeply engaged in various low-power design innovations of LED displays, with the purpose of reducing the overall power consumption of LED display from the design source through energy-saving innovation for driving technology, and leading the entire LED display industry to contribute to the ultimate realization of global low-carbon sustainable development goals.

When talking about the importance of energy-saving innovation, the head of Chipone LED Display Division said, as an innovation pioneer with a global market share of more than 50%, one of the important research and development directions of Chipone LED Division in the future is certainly to realize the energy-saving innovation for display driver. Because that is an unavoidable social responsibility for any industry leader in the ESG field.

As the LED displays has become more and more closely spaced, the challenges that plague all display manufacturers are not only the higher requirements for display performance, but also the difficulty in screen temperature and power consumption. The smooth implementation of "Baicheng Qianping” (a program for upgrading public LED displays) has accelerated the implementation of LED outdoor media advertising displays. In today’s low-carbon era, how to reduce the energy consumption of the displays has become a problem that must be addressed by the entire LED supply chain.

For the power composition of LED large display, the main relevant elements include LED lamp bead, driver IC, controller, line loss, conversion efficiency of switching power, most of the power composition is concentrated in the LED lamp bead, and the power consumption of driver IC in pixel pitch lower than 1mm applications increases greatly. According to the calculation formula P=V*I to reduce power consumption, the optimization and innovation of design can be made from the perspectives of current and voltage. In this regard, Chipone can provide the following relevant technical solutions.

Optimization of system voltage design

1. Low knee voltage driver reduces the power consumption by up to 20%

Low knee voltage driver technology can ensure that under lower knee-point voltage, the output current of driver IC enters into constant current area and drives the LED lamp bead stably. Low knee voltage driver technology can reduce the power voltage of the entire system, thus reducing the power consumption of the LED lamp bead and driver IC. It can reduce the power consumption by up to 20% compared with traditional driver scheme. Chipone’s driver ICs integrated with low knee voltage driver technology include ICND2046, ICND2150S, ICND2159, ICND2069, etc.

|

Common solution

|

ICND2046

|

|

VR=5V

|

IR=20mA

|

VR=4V

|

IR=20mA

|

|

VG=5V

|

IG=15mA

|

VG=4V

|

IG=15mA

|

|

VB=5V

|

IB=8mA

|

VB=4V

|

IB=8mA

|

|

Power

|

27.5W

|

Power

|

22W

|

Energy saving by 20% (only for the application conditions in the table above)

(27.5W—22W) ÷ 22W=20%

2. Common-cathode driver reduces the system power consumption by up to 30%

Since 2018, with the rapid development of Mini LED, common-cathode driver has become a preferred driver solution. The traditional common anode driver solution adopts unified power voltage, while the forward voltage of red lamp is 1V lower than that of green and blue lamps, so there is loss caused by excess voltage on red lamp.

When common-cathode driver circuit is introduced, the extra power loss of red lamp can be avoided by separate power supply for driver IC. The traditional RGB unified power supply mode can be changed into power supply of 2.8V and 3.8V separately to reduce the system power consumption by up to 30%. Chipone has developed and produced a number of common-cathode driver ICs, including ICND2049, ICND2069, ICND2159, ICND2210, etc.

Figure: Product Sample: ICND2159

|

Comparison of Parameters of Common-cathode and Common-anode Modules with Same Specifications

|

|

Item

|

Common-cathode (2069+2019)

|

Common-anode

|

|

Voltage

|

R:3V GB:3.8V

|

5V

|

|

Current

|

6.4A

|

6.29A

|

|

Power consumption

|

22.09W (30.7%↓)

|

31.45W

|

|

Initial lamp surface temperature

|

31°C

|

31°C

|

|

Lamp surface temperature after aging

|

43.5°C (12.4°C↓)

|

55.9°C

|

|

Red IC temperature

|

38.4°C (9.3°C↓)

|

47.7°C

|

|

Green IC temperature

|

43.4°C (6.4°C↓)

|

49.8°C

|

|

Blue IC temperature

|

41.3°C (5.9°C↓)

|

47.2°C

|

|

PCB temperature

|

40.8°C (7.4°C↓)

|

48.2°C

|

Optimization of system current design

For LED lamp beads, under the condition of constant luminous efficiency, reducing the current of LED lamp beads will directly affect the display brightness, while using bright LED lamp beads (high luminous efficiency) will greatly increase the cost. Therefore, the optimization of system current design mainly focuses on driver IC, and the design innovation can be made from the aspects of reducing the static power consumption of driver IC, dynamic low power consumption, and reducing the number of chips.

1. Low static power consumption design reduces the power consumption by 20%~40%

In order to achieve high-precision and stable current output and solve the problems such as coupling of low-bright quality, dark of 1st scan and color deviation, the design of driver IC contains the complex digital circuits and analog circuits such as current regulation module, pre-charging circuit, mbist circuit, detection module circuit, comparator and shift register. Although the design of more circuit modules can improve display performance, it also needs more power consumption, which brings great challenges at the design level. From ICICN2053 (the first-generation PWM driver) to ICND2153, Chipone has constantly made optimization and innovation in R&D and design, and reduced the power consumption by 20%; in particular, the latest ICND2165 series products not only improve the picture quality, but also reduce the power consumption by 40%, thus truly bringing an ideal innovation mode of "performance up and power consumption down".

2. Dynamic low power consumption design reduces the screen power consumption by 5%~10% and standby power consumption by over 50%

When black screen occurs, the traditional driver IC output channel will continue to be turned on , which results in unnecessary current waste. Therefore, Chipone has specially developed the dynamic energy-saving and black screen energy-saving technologies, which can be applied to close part of channels or most circuit modules of the chip to achieve dynamic low power consumption based on different display images and the data detected by the control unit in a predetermined period of time. The power consumption for different display images can be reduced by 5%~10%, and the standby power consumption can be reduced by over 50%. Chipone’s driver ICs with dynamic low power function include ICND2055, ICND2069, etc.

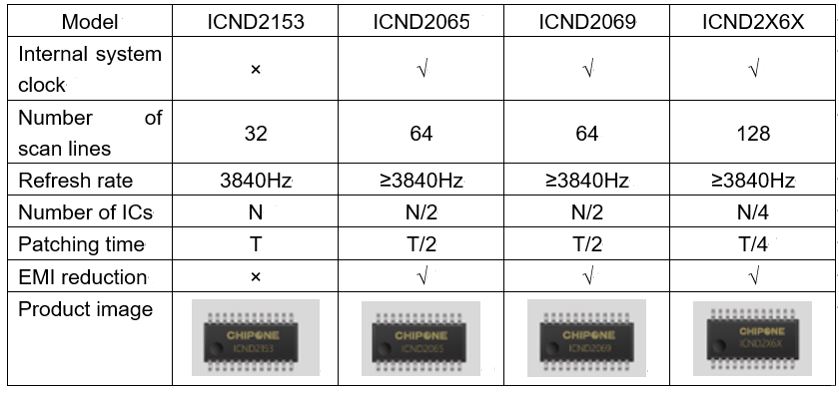

3. Improved scan design

In 2017, Chipone launched the first improved scan driver ICICND2065 supporting 1~64 scan lines, leading the industry to upgrade from 32-line scan design to 64-line scan design. The improved scan design reduces the number of ICs by half, accompanied with reduced power consumption and temperature, lower difficulty in PCB design and fewer PCB layers, improved patching efficiency, as well as further reduced overall cost of lamp board. Chipone has also successfully developed 128-line scan driver, and it will further optimize and improve the driver architecture.

4. With highly integrated design, the power consumption is only 20% of that of traditional 16-channel driver IC

To reduce the number of lamp board driver ICs, the number of scan lines can be increased, or the integration degree can be improved by increasing the number of driver IC channels, so as to reduce the power consumption of driver IC. Chipone has successfully developed and produced a number of highly integrated driver ICs, including the traditional 16-channel driver IC, as well as 24-channel, 48-channel, 96-channel, 120-channel and 360-channel highly integrated driver ICs with row and column in one. The super integrated driver IC, with its static power consumption per pixel accounting for only 20% of that of traditional 16-channel driver IC, is a preferred design solution and the driver IC particularly in pixel pitch lower than 0.9mm applications.

The arrival of a low-carbon era has brought the key innovation field of energy saving and consumption reduction for the innovation and growth of technical enterprises. In the future, to achieve the sustainable and healthy development of the LED display industry, the innovation in energy saving and consumption reduction for the whole industry chain will inevitably become a mandatory option for every enterprise. As a leader in LED display driver, Chipone will undoubtedly apply more advanced energy-saving and consumption reduction technologies to its own products in the future R&D and design work, so as to promote the low-carbon upgrade of the whole industry.

Huang Wengang, Chipone Technology (Beijing) Co., Ltd.