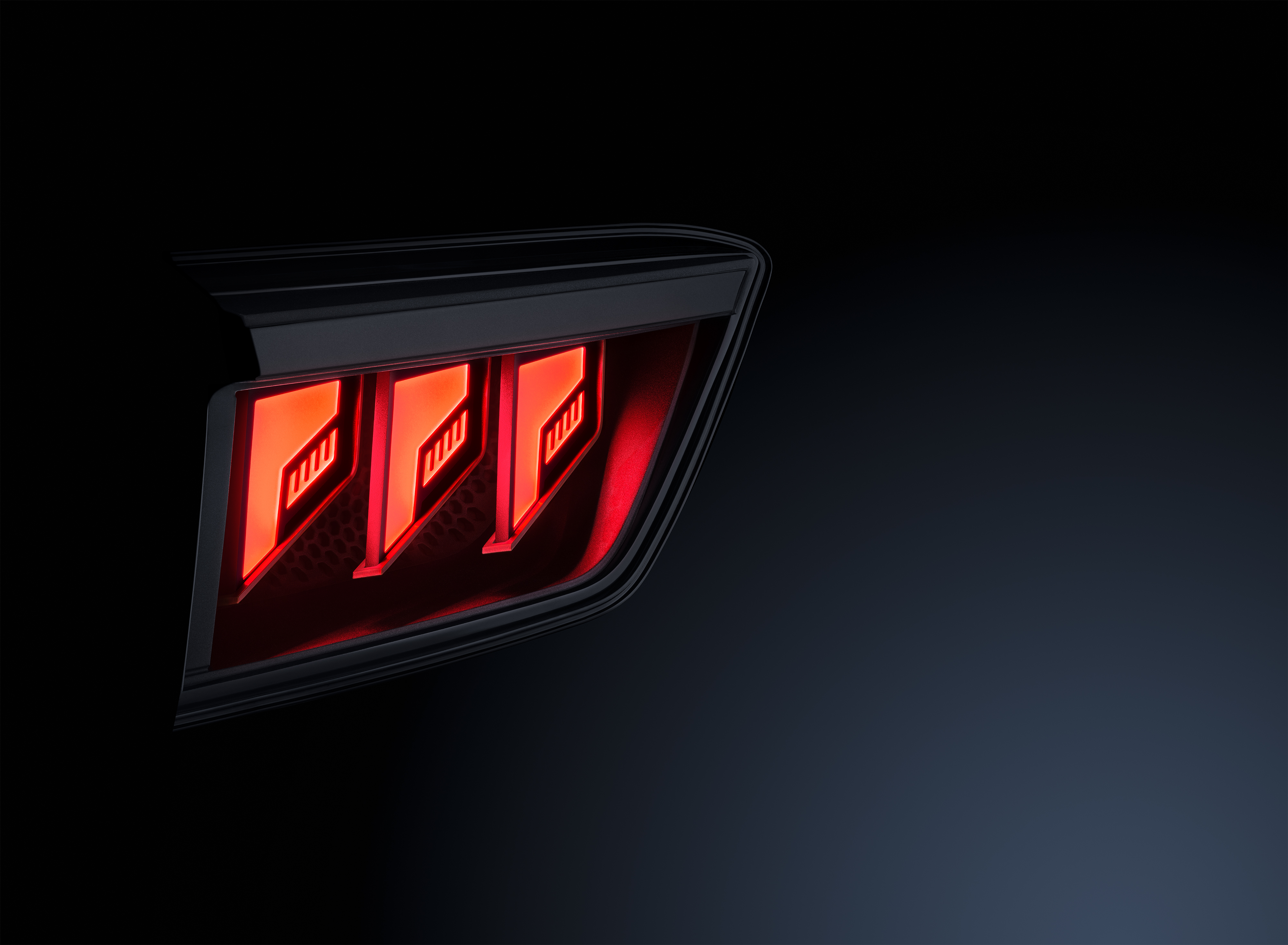

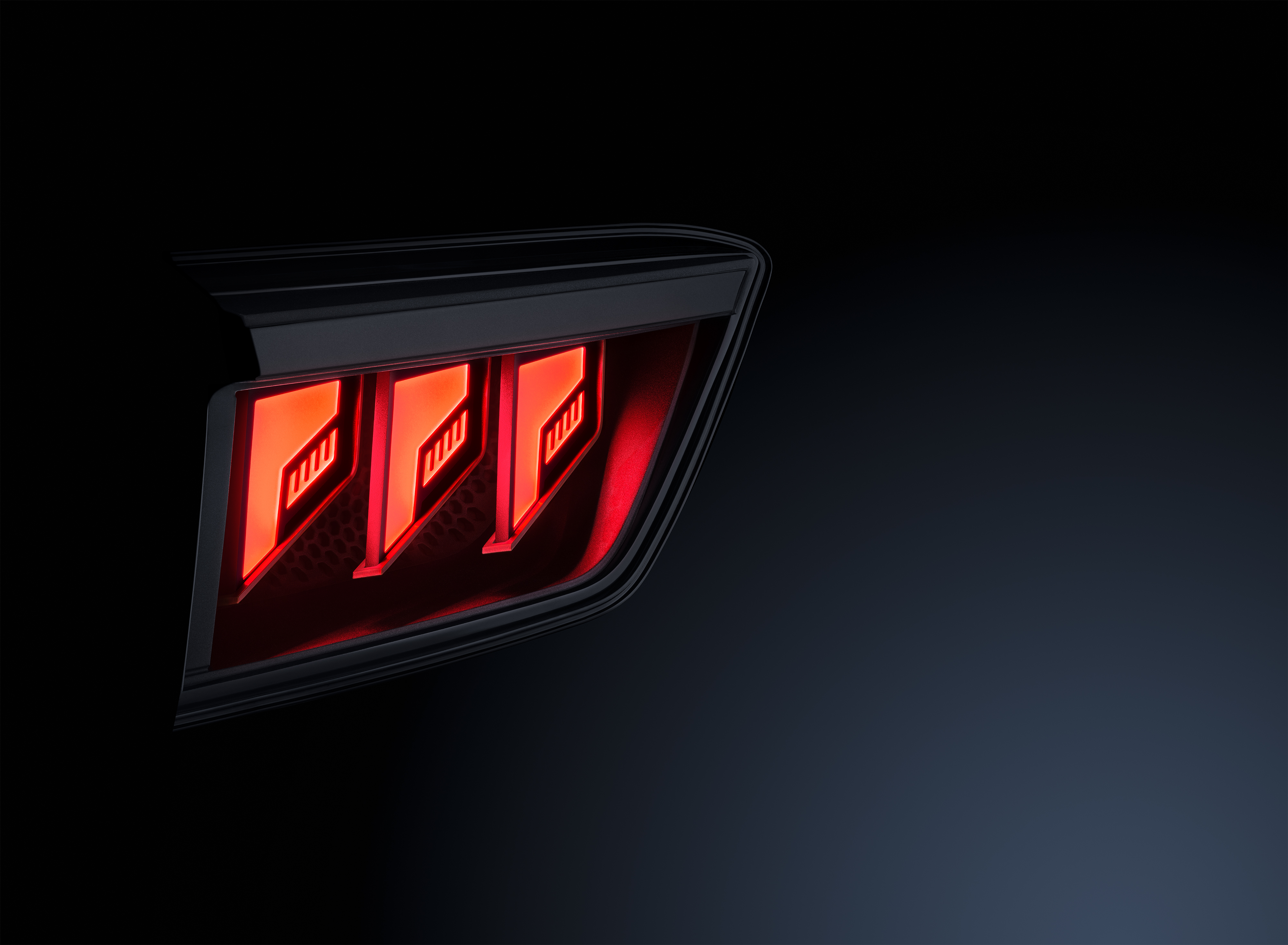

Based on the FlatLight technology, the various rear combination lamp functions can be implemented in just one optical element. (Picture: HELLA)

-

FlatLight technology to go into series production for the first time for an international car manufacturer as early as mid-2024

-

Light guide concept with particularly small optics reduces installation space requirements and weight and fundamentally changes the design of light signatures

-

Technology has around 80 percent lower energy requirements compared to conventional systems

Lippstadt, 13 October 2022 HELLA, the automotive supplier operating under the FORVIA umbrella brand, has received a customer order from an international car manufacturer for its innovative FlatLight concept. This is not only the first series order for this pioneering technology, but also one of the largest project acquisitions in HELLA's rear combination lamp business in recent years. The FlatLight rear combination lamp is scheduled to go into series production as early as mid-2024. It is developed at the company's headquarters in Lippstadt and in Mohelnice, Czech Republic. Production will start in Bánovce, Slovakia.

"With the market launch of our FlatLight concept, we are taking rear combination lamp technology to a completely new level and setting entirely new standards in terms of design, functionality and energy efficiency," says Yves Andres, Managing Director Lighting at HELLA. "In this way, we are underlining the fact that rear combination lamps have long since ceased to be relevant only for road safety, and now play a central role in brand differentiation and the unique positioning of car manufacturers."

The FlatLight | µMX technology, which HELLA will launch on the market for the first time in less than two years, is based on an innovative LED light guide concept with so-called micro-optics that are smaller than a grain of salt. This opens up numerous advantages: higher performance, more diverse design options, better integration into the vehicle. Thanks to the extremely shallow module depth, the required installation space is reduced by around 90 percent: While conventional systems require an installation depth of around 40 millimeters, FlatLight technology manages with just five millimeters. In addition, the different rear combination lamp functions can be implemented in just one optical element. As part of the acquired customer project, brake and taillight functions are combined, for example. In terms of installation space requirements, homogeneity achieved and efficiency, this cannot be realized with any other available solution. Based on the FlatLight technology, it would also be possible to integrate the flashing light. Another plus point is that it requires up to 80 percent less energy than conventional LED taillights on the market - while maintaining the same high lighting performance and homogeneity.

Parallel to the first series project, HELLA is pushing ahead with the development of the next FlatLight generation. For example, the technology could become digital in the future through the integration of a SmartGlass display, allowing the individual segments of the rear combination lamp to be controlled even more individually and precisely. On the one hand, this would allow a large number of customisable signatures to be realised and the range of functions to be significantly expanded. On the other hand, new, digitalized business models such as the uploading and customization of graphics via app or software update would also be conceivable.