UVC-LED technology is being highlighted as a key technology to replace conventional mercury lamps in the fields of water, air, and surface sterilization. Its importance became even more pronounced during the COVID-19 pandemic. However, when applying UVC-LEDs to real-world applications in the engineering field, we have consistently faced a critical technical hurdle.

That hurdle is 'Reliability.'

The primary applications for UVC-LEDs—such as water purifiers, HVAC (Heating, Ventilation, and Air Conditioning) systems, and home appliances—are almost always exposed to high-temperature, high-humidity environments where bacteria can easily multiply. Ironically, this environment is the most vulnerable condition for conventional UVC-LED chip structures.

The Fundamental Limitation of Conventional UVC-LEDs: Failure Mechanisms in High Humidity

As engineers, we must understand the fundamental reason 'why' failures occur. Conventional UVC-LED chips typically have an open structure where the anode (P-pad) and cathode (N-pad) are exposed in parallel.

This structure is extremely vulnerable to the penetration of moisture (H₂O) and ions (ION). When moisture infiltrates the chip, a chain of failure mechanisms is triggered:

-

Electrode Corrosion: Moisture acts as an electrolyte, oxidizing and corroding the metal of the P-electrode.

-

Ion Migration: Metal ions from the corroded anode migrate and accumulate on the cathode. This eventually causes leakage current between the two electrodes, leading to a short circuit.

Due to these problems, conventional chips exhibited catastrophic performance degradation within a few hundred hours in high-temperature, high-humidity conditions (85°C / 85% RH).

Of course, the industry has tried to solve this problem using 'Package-Level Hermetic Sealing' technology. However, this method requires expensive ceramic/metal packages and sapphire windows, which sharply increases manufacturing costs, causes optical loss due to the window, and increases the package size. This has been the biggest obstacle to expanding the UVC-LED market.

A Paradigm Shift: Solving the Problem at the 'Chip Level' (HUV Technology)

Elphoton, Inc. has developed 'HUV,' a UVC-LED chip with a new paradigm that solves this problem by changing the structure of the chip itself, not the package.

The core technology of HUV is its 'Fish Eye' or 'Closed-Loop Electrode Structure'.

-

Conventional Structure: The anode (P) and cathode (N) are placed in parallel, leaving a path open for moisture penetration.

-

HUV Structure: The cathode (N-pad) completely encircles the anode (P-pad) in a circular shape.

Thanks to this unique structure, when the chip is mounted on a lead frame, the outer N-pad joins with the lead frame via metal bonding, forming a perfect hermetic seal by the chip itself.

As a result, the path for external moisture or corrosive ions to penetrate the chip's core active region is fundamentally blocked.

Data Proves the Overwhelming Reliability

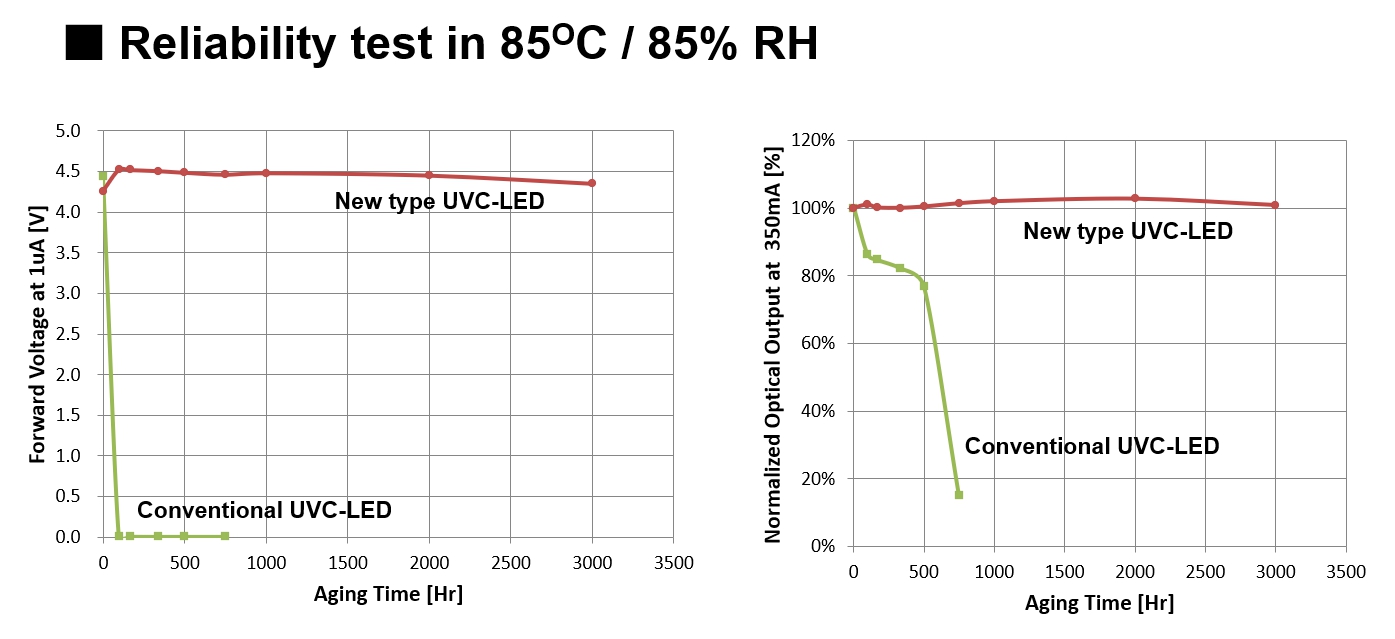

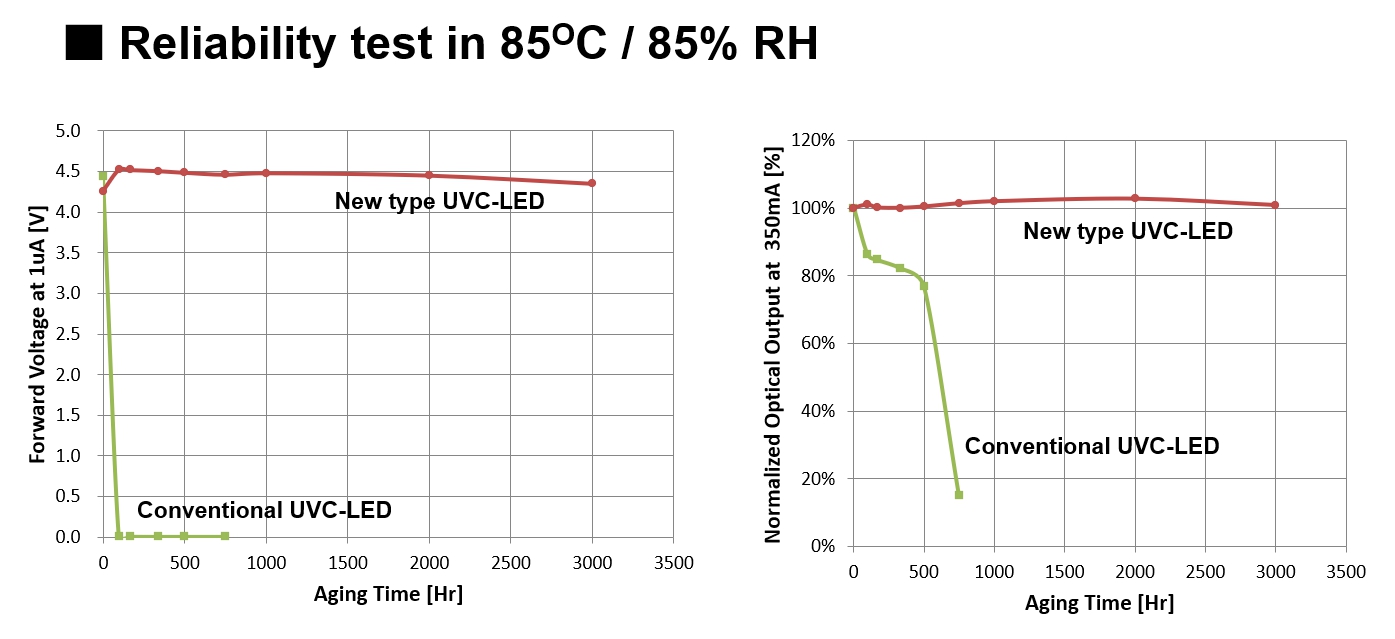

For an engineer, the most important thing is data. The hermeticity of the HUV chip was measured at 1.5 X 10-9 atm·cm³/s via a He Leakage Measurement test, confirming a near-perfect seal. This level satisfies the U.S. military standard (MIL-STD-883).

The most noteworthy data comes from the real-world environmental tests.

Reliability Test: 85°C / 85% RH (High-Temperature, High-Humidity)

-

Elphoton HUV: After 3,000 hours of operation, no degradation in optical output or physical damage was observed.

-

Conventional UVC-LED: Failed after approximately 500-800 hours, showing a sharp drop in optical output.

This data clearly demonstrates that HUV has fundamentally solved the reliability problems of conventional chips.

Conclusion: A 'Game Changer' for UVC-LED Design

Elphoton's HUV technology is a solution that fundamentally solves the biggest challenge for UVC-LEDs—the high-humidity environment—at the chip level. This is an engineering achievement that secures cost-competitiveness by eliminating the need for expensive hermetic packaging, while simultaneously capturing all three benefits of reliability, high performance, and cost-effectiveness.

This technology will change the design standards for all UVC sterilization applications that require high reliability and high output, such as water treatment plants, next-generation HVAC systems, and automotive climate control systems.