In 2006, High Elevation Technologies, now known as Ledder Technologies, along with leading LED manufacturer OSRAM, cross-licensed to the then public company Ya Hsin Industrial and became the world’s first company to obtain Osram’s General Lighting patent right. It was breaking news for the industry, however, because of Ya Hsin’s CEO’s personal reasons; the hope of LED lighting industry suddenly disappeared.

Now in 2011, with twenty years of research and development in patented technologies, Ledder Technologies solved the heat dissipation, glare, and power problems in LED lights from LED packaging to the actual light shell design.

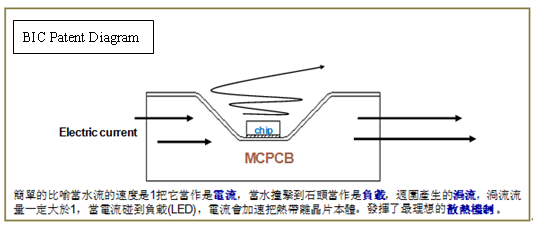

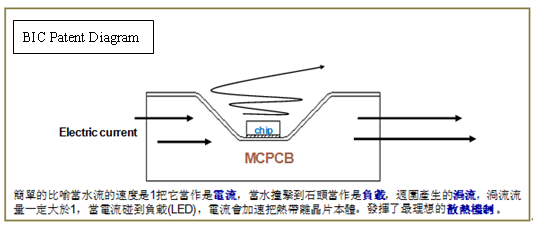

Ledder currently has several patented technologies, including Build in Concave (BIC) packaging and exclusive MCPCB substrate. A concave shape is created on the MCPCB substrate by using Ledder’s sole technique during the packaging process to resolve the heat problem. This specific packaging coupled with their heat sink and 3D optical design produces an LED light with high reliability.

Simple illustration: water is flowing at the speed of 1 and that is the electric current. When water hits the rock, that represents the electric load and the swirling current that happens surrounding that must be greater than 1. When the electric current meets the electric load (LED), the current will speed up and bring the heat away from the chip itself, performing the ideal heat dissipation mechanism.

Ledder Technologies dissipates heat away from the bottom of the LED chip by using their patented packaging process along with their heat sink design. Also because MCPCB conducts heat 100 times better than LED substrate, the heat can be effectively conducted from the LED substrate through the MCPCB substrate. In turn, the LED chip can actually be used for 50,000 hours and not shorten its life span and still maintain its temperature below 55∘C. Through this fundamental characteristic, Ledder’s street lights carry out the green,environmental, and durable spirit of LED. As a result, Ledder’s patented BIC packaging process and patented heat sink application not only completely solved the heat problem but also made application of LED lighting products practical.

Dr. Peter Pan personally demonstrated using three times the high-voltage current (1.05 amps) to continuously power Ledder’s light bar, which is produced with patented BIC packaging and MCPCB substrate, to prove its product durability. During the demonstration, the chip did not break or burn out. On the contrary, the chip became much brighter.

From left to right: Professor Dave T.T. Chang, LET inventor professor Milton Fent, Dr. Peter Pan, Mr. Danny Lee

Ledder Technologies’ 120W LED street lights participated in Australia’s street light stress test with world’s top 11 LED manufacturers and brands. After the Australian electric and telecom companies test the lights for as long as eight months with salt damaging, lightning, acid etching, ion impacting, snow frosting, and various field tests, Ledder’s products are the only products that maintained its data with no light degradation and no flare. Thus, Ledder became the sole company to acquire Australia’s first LED street light order with its strength in quality.