Established in 2009 in Xinyu, Jiangxi, China, WG Tech went public on the Main Board of the Shanghai Stock Exchange (ticker symbol: SH603773) in 2018, standing as a leading Chinese enterprise in the research, development, and manufacturing of glass-based printed circuit boards and related electronic components. The company adheres to a development strategy driven by technological innovation and has successively received recognitions from the government, such as the National High-Tech Enterprise, National Center for Enterprise Technology, National Industrial Design Center, National Postdoctoral Programme, and National Intellectual Property Advantage Enterprise. With a range of self-developed technologies for glass-based printed circuit boards, WG Tech is among the few companies throughout the world that possess complete process capabilities and corresponding production equipment.

WG Tech not only focuses on advanced semiconductor packaging substrates but also pays close attention to advanced displays such as Micro LED self-emissive displays and Mini LED backlighting. According to a TrendForce survey, WG Tech’s products have been mass-produced and supplied to Hisense’s Black Obsidian Screen technology (including the Hisense Dasheng G9), Ledman’s 220-inch 4K P1.25 Mini LED display, and Mini LED displays from South Korean manufacturers. TrendForce had the honor of having an exclusive interview with WG Tech Group’s President, Awa Chang, at Touch Taiwan 2025, during which she shared the company’s insights into the advanced Micro/Mini LED display markets and the latest status of product development planned for 2025.

Awa Chang, President of WG Tech Group

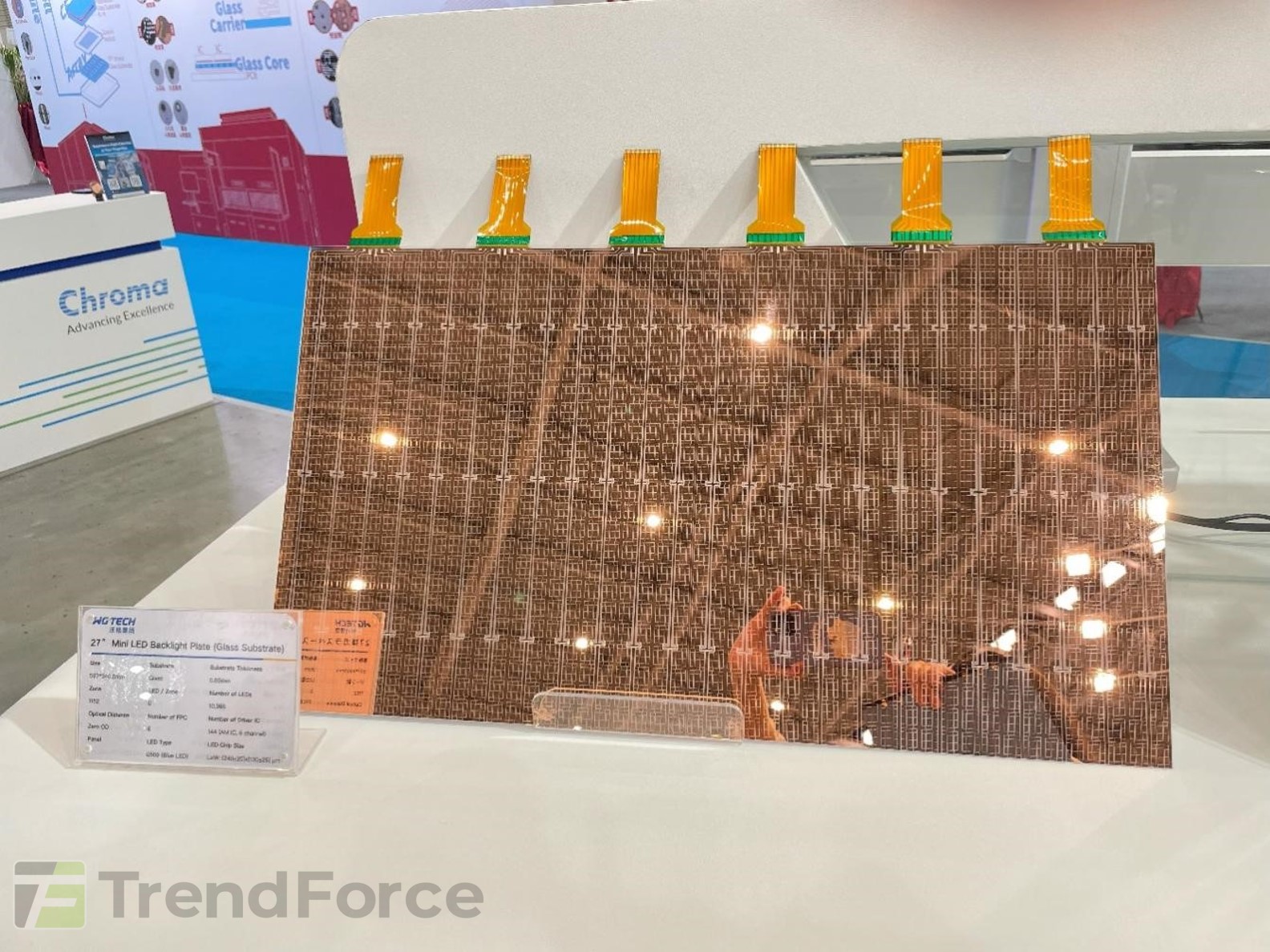

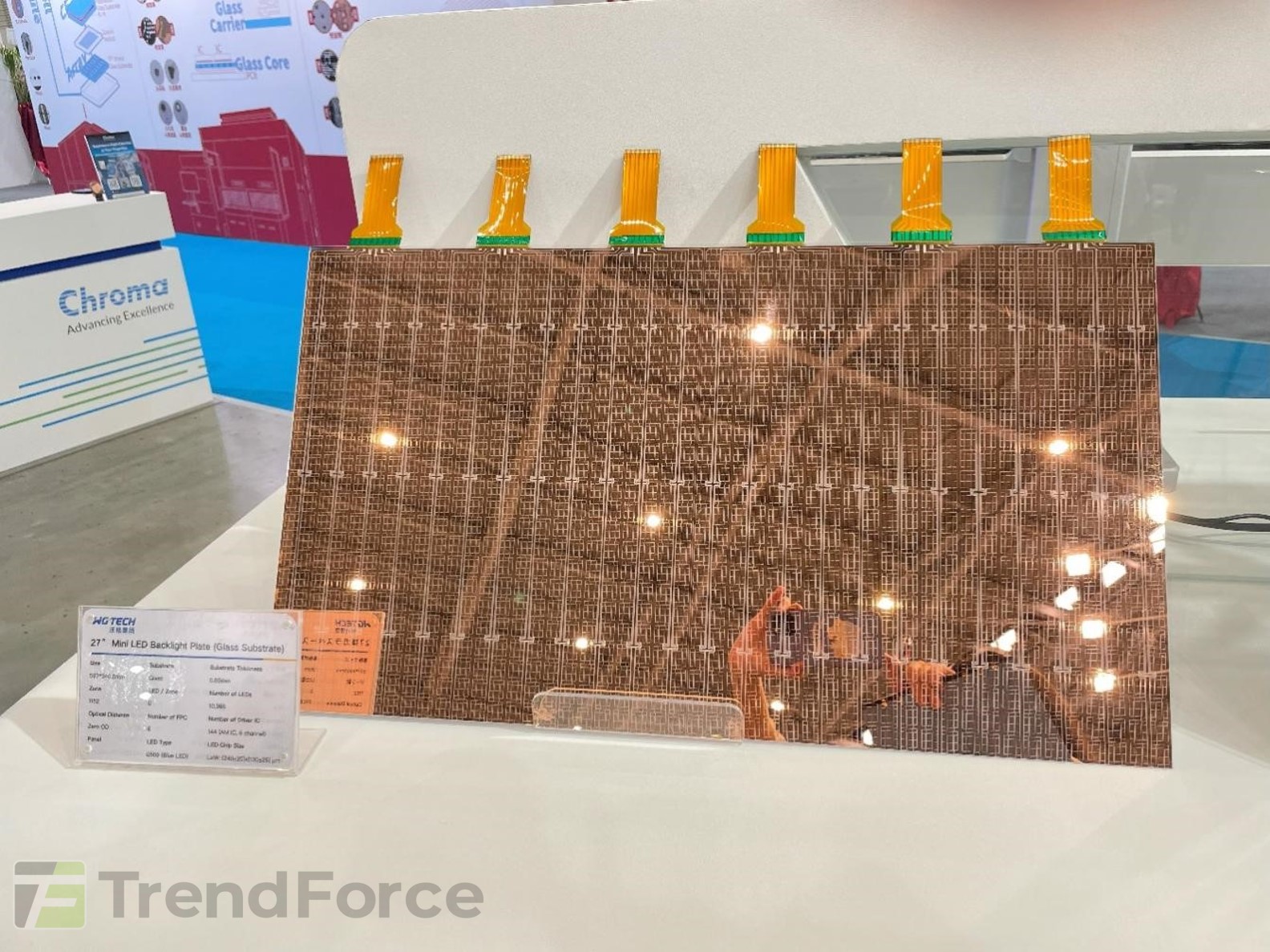

As Chang indicated, with strong customer support, product advantages, group resources, and extensive industry customization experience, WG Tech is able to meet customer demands while continuously exploring innovative market opportunities in advanced displays. WG Tech has launched exclusive glass substrate technology featuring high brightness, high contrast, high flatness, and excellent thermal dissipation performance. This technology is specially designed for high-end displays to create ultra-thin Mini LED backlight modules with “zero optical distance,” successfully addressing the halo effect issue. The 27-inch ultra-thin Mini LED display comprises a 0.55mm thick glass substrate, featuring 1,152 high-density dimming zones and incorporating 10,368 Mini LEDs to achieve precise light control. Hisense’s recently released Dasheng G9 display is powered by its exclusive Black Obsidian Panel technology and combines Mini LED COG with WG Tech’s glass substrate technology. By leveraging the core advantages of high-precision glass substrates with extremely narrow wiring widths and pitches, the display offers 2,304 independent dimming zones, significantly enhancing display performance compared to its counterparts.

In response to the demand for wide color gamut from displays, WG Tech has further developed its Magenta QD technology, which delivers a wide color gamut performance comparable to OLED products. By combining KSF red phosphor powder with quantum dot technology in a green film, it achieves high brightness and an impressive color gamut nearing 90% of the BT.2020 standard, while reducing power consumption significantly by 10-20%.

The 65-inch ultra-thin Mini LED TV comes with 2,304 dimming zones powered by 36,864 Mini LEDs, offering a wide color gamut covering 105% of NTSC. The rear view showcases the dynamic demonstration of glass substrate backlighting achieving outstanding precision in light control.

Regarding development of the Micro LED self-emissive display market, Chang further stated that WG Tech possesses proprietary PVD thick copper coating technology, precise circuit layout, micron-scale perforation, and advanced glass processing techniques, providing high-density, high-reliability packaging solutions for the semiconductor and display industries. The manufacturing process for Through Glass Via (TGV) glass is divided into two main categories: via-first and via-last. Currently, the mainstream approach is via-first, which is simpler and was the first to be applied in the market. The conductive material used is primarily low-resistance copper, and the holes are filled through electroplating. For ultra-fine pitch displays with a pixel pitch of ≤P1.0, the excellent flatness of glass can be utilized improve related process yields. Glass substrates combined with passive matrix (PM) driving schemes light up Micro LED displays through row-column scanning, featuring a simple matrix structure, mature technology, and pulse-width modulation (PWM). However, this approach also faces technical challenges such as the massive drilling of vias on glass substrates and the fabrication of thick copper layers (7µm) on glass. WG Tech’s products have been mass-produced in Ledman’s 220-inch 4K P1.25 Mini LED display and Mini LED displays from South Korean manufacturers.

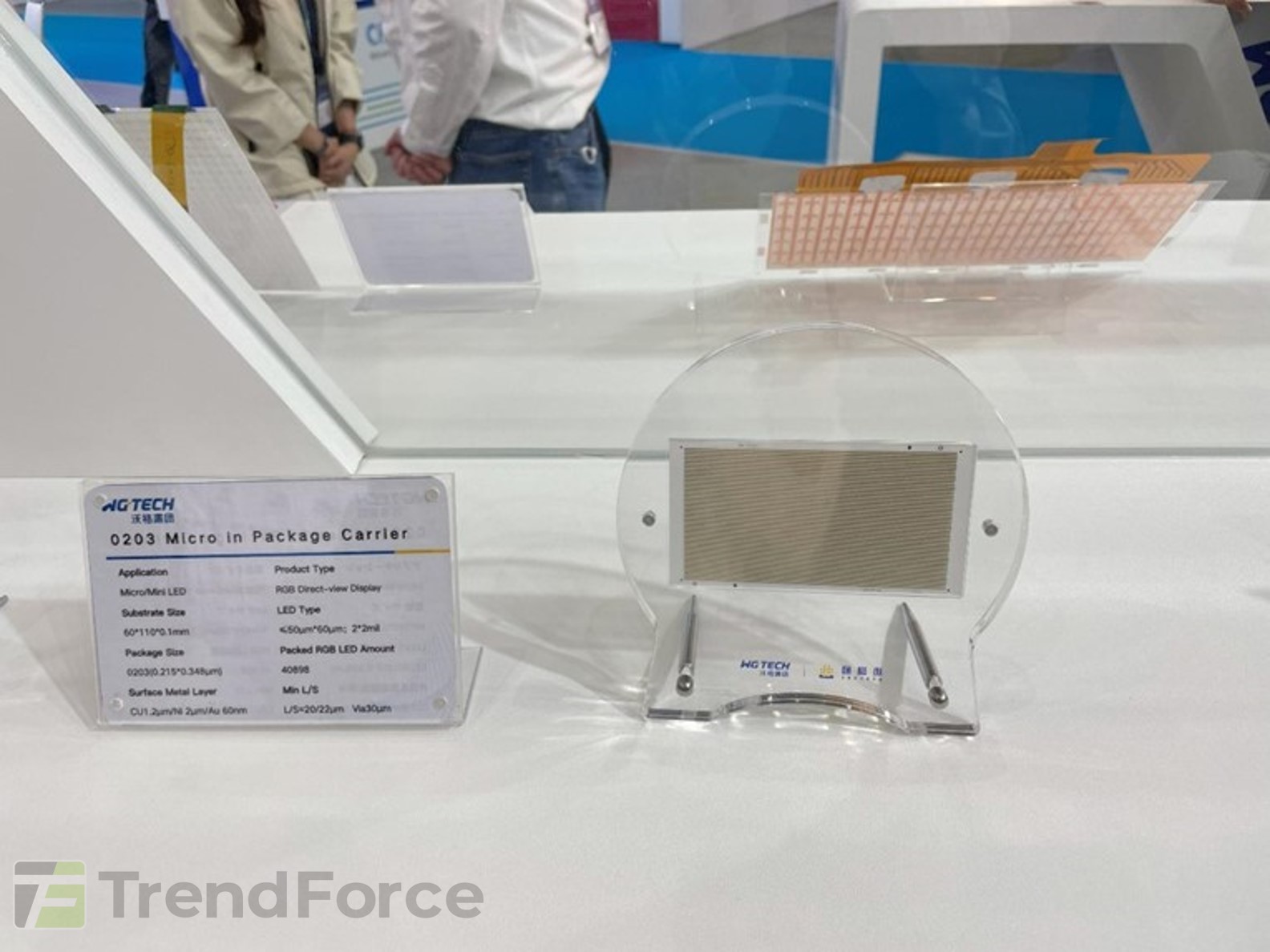

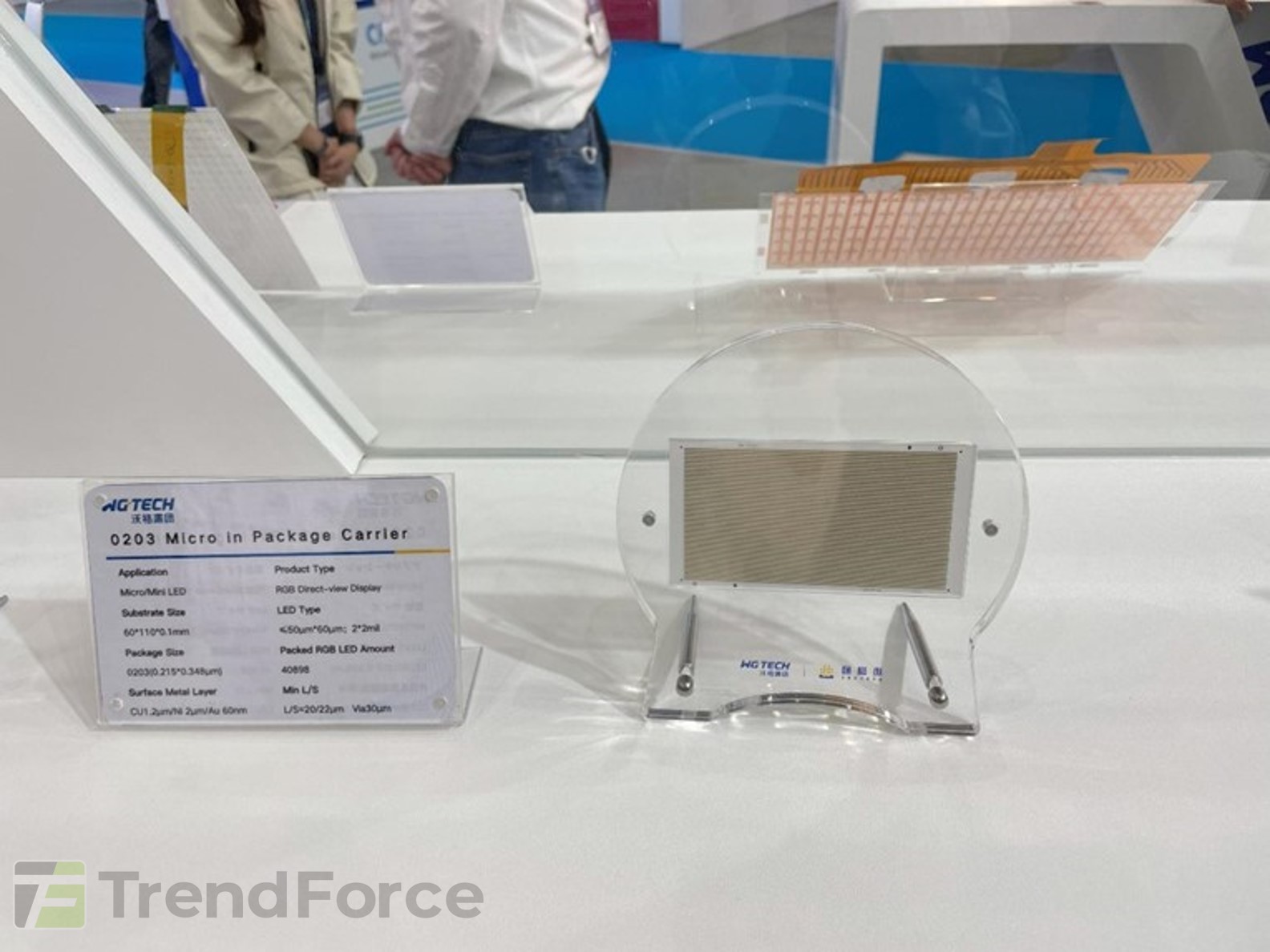

In response to the rise of micro-display LED packaging technology—MiP (Micro LED in Package), WG Tech has launched its 0203 / 0404 MiP glass substrates. The 0203 MiP model genuinely reflects the concept of Micro LED in Package, featuring 02x02mil (50x50µm) Micro LED chips.

As for the company’s development and market outlook for 2025, Chang emphasized that WG Tech is investing RMB 1 billion to expand capacity in glass substrates, die bonding, and SMT, with a total annual production capacity of approximately 4 million glass substrates—equivalent to about 8 million 32-inch displays. In response to the premium display market development, the focus for Mini LED backlight applications will be on single-sided, dual-layer circuit technology, targeting the RGB Mini LED TV market. The year 2025 is expected to celebrate the commercialization of glass-based Mini LED technology, marking a milestone. At this critical moment, WG Tech will officially launch its revolutionary Mini LED backlight product with 2,304 dimming zones, signaling a new era in display technology. As the market continues to demand higher display quality, the substrate manufacturer foresees that the technical development trend for Mini LED-backlit TVs will ultimately target top-tier specifications featuring 4,608 dimming zones. Notably, achieving such high-spec 4,608-zone substrate manufacturing can only be fulfilled by adopting glass substrate (COG) technology, which meets the stringent requirements for high-precision circuitry. This further establishes the irreplaceable role of glass substrate technology in the premium display sector. Responding to requests from Chinese and Korean customers, WG Tech is actively developing P0.625 TGV glass and exploring the integration of TGV glass with active matrix (AM) driving technology. Together with its customers, the company aims to drive the takeoff of the large-size Micro LED (COG) display market.

By Joanne Wu, TrendForce

TrendForce 2025 Global LED Video Wall Market Outlook and Price Cost Analysis

Release Date: 30 September 2024

Language: Traditional Chinese / English

Format: PDF

Page: 302

TrendForce 2024 Micro LED Market Trend and Technology Cost Analysis

Release: 31 May / 30 November 2024

Language: Traditional Chinese / English

Format: PDF

Page: 160-180

|

If you would like to know more details , please contact:

|