In this article Cirrus LED Systems outlines some of the trends in the LED signage industry.

The Current Design Revolution in The LED Signage industry

A few years ago it became clear that the LED signage industry needed a change. Fundamental shifts in LED technology, plus continual breakthroughs in software and hardware, and new innovations in competitive digital screen technologies, will force the LED sign manufacturer to adapt or die.

|

|

(All photos courtesy of Cirrus LED Systems) |

Hardware is getting lighter, smaller, and faster. Microprocessors and microcontrollers get more effective every day. Moore’s law dictates that the numbers of transistors per square inch on an integrated circuit doubles every eighteen months. Advances in software are reinventing the way we see the world at an accelerated pace. Just think of all that can be achieved with something a small as a cellphone -or an Apple watch.

Manufacturers of electrical devices are forced to develop more energy efficient and green products to stay competitive. Not only because consumers are more environmentally conscious but, because they are also protective of their wallets. Nobody wants to spend extra money on increased energy consumption.

Competitive digital display technologies are also becoming brighter, sturdier, and cheaper. If the LED advertising board doesn’t make the changes required to keep up to date with today's world, other technologies (or smarter LED sign manufacturers) will take over.

Every part of the LED board needs to be deconstructed and rethought with customer experience and technological advances in mind. Here are some of the things that any savvy LED display manufacturer has to keep in mind when designing their panels if they want to survive the competition.

More Energy Efficient LED Panels

Re-thinking the way electricity is used within an LED display sign is not only about reducing waste -and ergo reducing costs- but also about increasing the reliability of the LED boards.

There is a well known scientific principle, the law of conservation of energy, that states that energy can not be created or destroyed, but it can be transformed. Electricity, is an energy source, and as such, anything “wasted” is not destroyed but transformed into something else. In the case of electricity, it transforms into heat by a process called resistive heating. When any electrical device - such as an LED display - produces too much heat, the delicate and small components inside of them risk overheating and failing.

Resistive heating is the result of the friction that the resistance of any material causes when an electric current flows through it. Some materials, like wood, offer a lot of resistance while others, like copper, very little, but there is always some resistance that produces heat. According to Electric Power Systems: A Conceptual Introduction: “This resistive heating is the result of “friction,” as created by microscopic phenomena such as retarding forces and collisions involving the charge carriers (usually electrons); in formal terminology, the heat corresponds to the work done by the charge carriers in order to travel to a lower potential.”

Joule’s first law (Q= I2*R*T) states that the amount of heat released (Q) is equal to the square of the electric current flowing through a conductor (I), multiplied by the resistance of the conductor (R) and the amount of time this happens (T). So in order to reduce the amount of heat lost, or released, we need to diminish I, R and/or T. Let’s study each one of them:

R = To reduce the resistance of the conductor, most electronic devices (including all LED displays in the market) use copper. Copper is known for its low resistance -or high conductivity- properties.

I = Electric power can be transmitted at different voltages. As counterintuitive as it sounds, the higher the voltage, the lower the current. Why is that? The amount of electric power is equal to the product of voltage and current (P= E*I ). At higher voltage, lower current is needed to obtain the same amount of power. That is why electricity is transmitted at higher voltage and then converted to lower voltage through transformers present in most electrical devices. LED sign systems in particular have one or more transformers to lower the voltage of the electricity coming out of the outlet.

T = This is a simple concept, the longer it takes for the energy to travel, the more heat it loses. In the LED signage industry that would translate as the more the energy needs to travel -or the longer the cable inside the LED board- the more the panel will heat up.

In practice, since we can’t reduce R, unless we want to invest in gold cables, we need to work on reducing I and T.

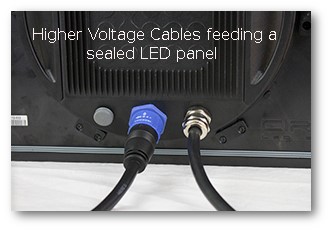

Traditionally, LED signs -as the one in the picture on the left- have one, or two big transformers that reduce the voltage. Cables run from that transformer to the different parts of the sign, taking the energy to each of the LED boards and then powering every LED. That means the lower voltage energy has to travel long distances to reach each diode. As we learned before, when low voltage energy travels, it wastes large amounts of electricity and produces heat. The heat needs to be dissipated and to solve that, traditional LED signs have fans inside, that in turn, consume more energy, need more cables, and produce more heat.

|

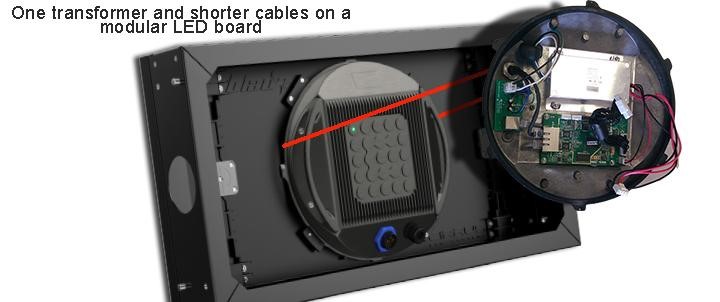

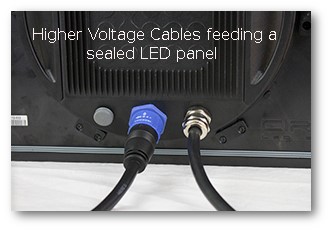

An intelligently designed LED display should aim to reduce the length of those lower voltage cables. How can that be achieved? By placing one transformer right on the LED board that it powers. The amount of heat generated diminishes tremendously if higher voltage cables take the energy from one LED panel to the next (see image on the right) and each one of the boards contains it’s own transformer that lowers the voltage right where the energy needs to be used (see picture below in the next section). This way, the LED panel not only consumes a lot less power- lowering the energy bill- but also runs a lot cooler than traditional LED signs. Therefore, it doesn’t need inside fans, which lowers the energy consumption and heat generated even more.

Moreover, if the LED display doesn’t use it’s power supply at it’s maximum capacity, the energy is used much more efficiently. This makes the LED sign run cooler and be less prone to failure. Why is that? Let’s imagine you need to get to a place far away from you are, you have two options you can either run or walk. If you run as fast as you can - use the transformer at it’s full capacity- your body will not only overheat quickly but will be able to sustain that intensity for a while before it fails and you can’t move any longer. On the other hand, if you pace yourself and walk, you will be able to travel a much farther distance before you start warming up and even much longer before you are forced to stop. Same happens with the transformer, at full capacity the transformer will overheat and give out quickly.

|

When deconstructing the LED module, every aspect has to be thought out. Just like Apple does with each one of their products, the LED board not only has to look and feel modern, but has to use every possible principle of good product design. For example, a clever idea used by Cirrus Systems, is in the outer design of the board. The back of the panel looks slick and cool but aesthetics was not the only concern when designing it. The vertical fins that you see in the picture create a convection cooling effect. What does that mean? Hot air rises, most of us know that. It is what allows unpowered aircraft to fly and makes the second floor of any house harder to cool off than the lower floor. Well, Cirrus Systems engineers used that principle when designing those fins. The temperature generated inside board warms up the vertical fins and the heat rises, which forces the cooler air to surge from the bottom. This creates a tunnel of cooling air that passes through the LED panel.

Lighter, Thinner and Enclosed LED Modules

There are a lot of advantages an LED sign has that no other screen can match -eg. Level of brightness-. Nevertheless, electronic devices are getting thinner, lighter, and slicker, and customers demand the same from their LED advertising boards. The old, bulky, outdated looking cabinet won’t cut it any longer. In the end, LED signs are an advertising tool, portraying the business image to the passersby and sign owners want to appear modern and sophisticated.

The tendency is towards simpler, enclosed, modular LED signs. Not only for aesthetic reasons; sealed, cleaner LED modules are less prone to failure, complications, and are significantly easier to service.

In cabinet style LED signs, each one of the panels has a sealed face with exposed electronics on the backside (see picture in the previous section) that are covered by the cabinet they are bolted onto. Inside the cabinet, the fans blow air sucked from outside to keep them cool. This outside air is filled with contaminants and moisture, which are particularly deleterious to electronics. Self-contained, sealed LED panels without fans and bundled cables not only produce less heat but protect the electronics against damaging agents much more effectively.

|

In addition to that, sealed panels allow for a modular design: Where the LED panels can be assembled like a puzzle, simply by snapping one with the other. What are the advantages of a modular LED sign? For one, it is a lot easier to service. If there is a problem, all the parts are enclosed in one LED panel that can easily be removed and replaced. Cabinet style LED signs require an expert on location to open the sign, study the nest of wires, and try to detect the problem or send the whole sign back for repairs. Furthermore, modular LED panels can be kept in stock and shipped within 24 hours of ordering the sign. Cabinet style signs require months to be assembled and shipped from overseas.

More Intelligent LED Hardware

The Apple iPhone introduced the advantages of integrated multi-sensor technology to the masses and that changed what we expect and the way we interact with technology forever. Again, the LED manufacturer should strive to keep up with the “Jobses” and utilize technology advances to make their signs smarter and more effective. There are several ways logic can be programmed into sensors embedded into the LED sign to make life easier for the sign owner, increase customer satisfaction, and reduce customer service costs.

Here are several types of sensors and some practical applications that we have thought of for them. We are sure that there are several uses that we haven’t even conceived that our readers could come up with and change the LED industry forever.

Temperature sensors: As the name indicate, they measure the temperature of a device. Temperature sensors can help detect if an LED board is getting dangerously close to overheating, send a notification over the cloud and shut the panel off before failure occurs.

Current sensors: Measures currents and voltage within a device. Again, a current sensor within an LED module could trigger an alarm and automatically shut off in the case of an overload.

Position Sensors: Detects motion in a device. From accelerometers to gyroscope sensors, position sensors allow our GPS to navigates us, our phone to know if it’s positioned vertically or horizontally, and our game console to know when we are hitting that ball. Still, it can also be a game changer in the LED signage industry, allowing each one of the panels to recognize its position within the sign and communicates it to the CPU. The CPU can then identify where and in which panel each pixel should be and map the panels automatically. This can save a lot of time and money in customer service and make the customers feel like LED sign installation is a breeze. It also allows customers with modular signs to change the shape of their signs easily if they so want to.

Humidity sensors: Measures changes in moisture and could send a message alerting if water has entered the sign.

Light sensors: Detect light and could automatically change the brightness level of the sign based on the amount of light it detects in it’s surroundings.

Capacitive sensors: The sensor detects changes in capacitance, to indicate for instance, the location of your finger on a board. We have not come up with an LED signage use for this but we invite you to do so. And while not directly related to the sensor but considering that nowadays adults spend increasing amount of time on their mobile devices, it is important for the LED manufacturer to offer the customer easy interaction with their display, which includes high-end software that can be access not only from a computer but also from phones and tablets.

Pressure and strain sensors: Measures changes in pressure. Sensors could be place for signs in regions under exceptional duress - extreme high altitudes or severe high winds- though it most likely won’t be cost effective.

Many more inventive applications can be devised for each one of these types of sensors to improve LED displays.

Controllers should also be smarter, constantly monitoring the health of the display, making adjustments, and sending messages to the users. For example, there should be constant communication between the CPU in the controller and each of the tiles, so the CPU can notice automatically if one of the panels stopped transmitting. That way, if that happens, the owner can receive an alert on his or her phone even if noone is looking at the sign at that moment.

Other logics could be programed into the sign to make diagnostics and repairs easier. For instance, logic programed into a light indicator that blinks in different ways or changes colors (or turn itself off) to indicate problems like: The tile is not getting data, the tile is not getting power, the tile is not getting the image/ video feed, etc.

Top Of The Line LED Cloud Software

I have written extensively about this topic, if it interests you, I invite you to read more about it. Still, one thing that is often overlooked when discussing LED display manufacturers is the software that controls their signs.

LED signs normally come with a free, pre-installed LED software without which the display screens can’t run. Yet, the better and more user-friendly that the LED display software is, the easier it is for the business to create and modify eye catching messages.

A high-quality software can be the difference between a successful LED advertising display and one that fails to attract new customers. It should give the sign owner the flexibility it needs to make their programmable message board the most effective form of advertising.

LED display software should allow to easily produce professional quality images and videos. Furthermore, the interface should be very user-friendly to effortlessly create schedules, offline playlists, and change the message.

LED Manufacturer is Your Choice: Adapt or Die

The ways technological advances can be used to further improve the LED signage are immeasurable. All other electronic devices and digital screens are evolving and so are customer’s expectations. The LED sign manufacturer can’t afford to a lag. New innovations bring cost saving technologies, more effective signs and happier customers.

Download the whitepaper here