Until now, the basic design of an LED lamp has remained fundamentally unchanged. The common formula has been to use a single, high power GaN chip (or a few larger chips), add phosphor (remotely or directly), and drive the chip(s) with as much power as possible to yield the maximum amount of white light. The key to the longevity of the lamps is to effectively dissipate the heat that is generated by the large LED chips. This is why so many LED lamps have large heat sinks added to the base of the lamps.

|

|

(All Photos Courtesy of AXP Lighting) |

A new technology trend has emerged, Filament LED. The use of heat sinks for heat dissipation has been eliminated completely, resulting in a lighter weight lamp that costs less, and has the look of a classic incandescent lamp.

In the Beginning

First introduced in 2008 by Ushio Lighting, the initial goal of Filament LED lamp was to preserve the look of the classic Edison light bulb as illustrated in Picture 2. Unfortunately, the product did not gain widespread market acceptance due to poor thermal dissipation and incomplete flux geometry.

The response by lamp makers was to go to a single large LED chip (or large matrix of chips), and add massive heat sinks to address the thermal issues created by using the large chips. Sadly, nearly all of the lamps created over the next several years rely heavily on the use of bulky heat sinks to handle the thermal management issue, and therefore provide only 180 degrees of flux geometry. Clearly, this is not the ideal solution.

Scientific Study + Market Reaction

The Swedish government, with support from the Belgian government, CLASP’s European Programme and the European Council for an Energy Efficient Economy submitted a report on November 19, 2014, to the European Commission and the Consultation Forum to highlight the emerging trend of the LED Filament approach as used in a new breed of LED lighting products.

Some of these new LED products have been introduced into the N.A. and European markets at low prices. The fanfare caught the attention of the Swedish Energy Agency and its affiliates in Europe who decided to investigate the LED filament A19 in Q3 of 2014. The report confirms the LED filaments used in the new breed of LED lamps have a great potential as they are more efficient than many conventional LED lamps, and the new lamps provide better flux geometry.

Even with this positive report, Filament LED products have been slow to be adopted in the North American market for two reasons. Only two (AXP Lighting and Lighting Science Group) of the dozens of Filament LED lamp manufacturers are certified by UL, and only one (AXP Lighting) has received both UL and Energy Star certification.

Filament LED lamps – Not all are created equal

This article will analyze “Filament LED lamps” like the example shown in Picture 3. The study also benchmarks several clear LED lamp designs, those based around optical light guides offered by companies including IKEA, OSRAM and Philips.

The most common use of filament style lamps is in retro lamps, i.e., clear glass lamps that allow the “filaments” to be seen. These look particularly good in flame-tip chandelier lamps. While the look may appeal too many as a throw-back to the old-style, classic incandescent lamps, a practical advantage of the filament is that the LEDs can be configured for omnidirectional light, the same as an incandescent lamp. This type of 360 degrees flux geometry has been lacking in most LED lamps on the market today.

Key Design + Construction Techniques

Beyond their similarity to the original Ushio filament lamps, there are actually many novel and effective design elements in the new wave of Filament LED lamps, which make them superior to first generation LED lamps. For starters, the LED “Filament” typically consists of many (sometimes hundreds) of tiny unpackaged LED chips mounted on a transparent substrate instead of metal substrate. This is commonly referred to as Chip-On-Glass (COG). These transparent substrates are made of glass or sapphire materials. This transparency allows the emitted light to disperse evenly and uniformly without any interference. This enhances the flux geometry of the lamp. The LED filament is then encapsulated in a resin made up of a silicone and phosphor mixture that performs the usual transformation of the LED chips’ blue light into white light. This innovative design allows the use both of both blue LEDs as well as red LEDs to modulate the color temperature. Most manufacturers rely solely on the phosphor to set the color temperature. This added degree of control allows the lamp maker to provide a more accurate level of color temperature, and flexibility during the manufacturing process. The downside is that the CRI performance will not be as consistent when using the combination of both blue LED and red LED chips.

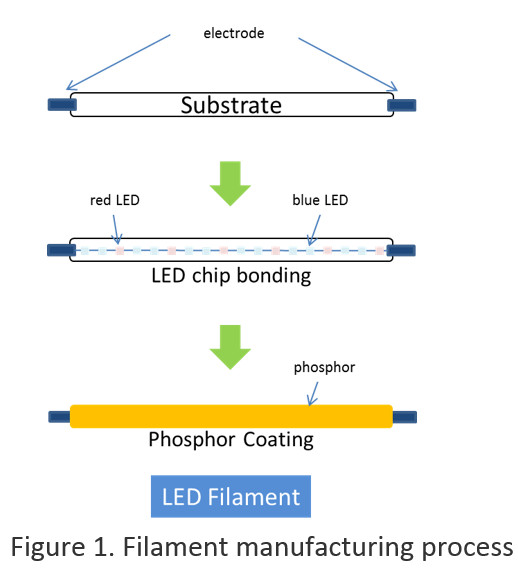

One area to note is that using low-grade silicone to cut cost is a common practice among many of the LED filament lamp makers in China. Low-grade silicone will become brittle after 200 hours of operation. It will cause the filament structure to fracture and to break the wire-bonded LED string. This is why the use of high-grade silicone is vital to the long life of the LED lamps. Each end of the filament has a metal electrode for further assembly. Figure 1 shows the step-by-step manufacturing process of the LED filament.

The phosphor coating is critical to the CRI performance and the safety of the LED filament lamps. Improper coating of the phosphor can induce leakage of the blue LED light, which can be harmful to the retina as some reports have suggested. One Filament lamps maker, AXP Lighting, has developed a novel phosphor deposition process which eliminates blue light leakage.

First generation LED lamps are typically built with large size LEDs, then they are driven with high current for maximum performance. Filament LED designs achieve even better performance than their traditional LED lamp counterparts by under driving many smaller, low power LED chips. The result is less heat, better efficacies, and sleeker designs with no heat sink needed. First generation LED lamps, on the other hand, need large heat sinks, which in addition to adding cost, also interrupt the flux geometry, which is why traditional LED lamps can never provide a true 360 degree flux geometry.

It’s all about the Heat

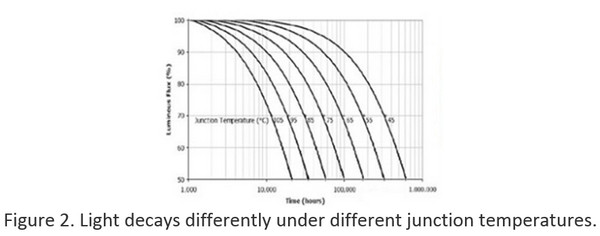

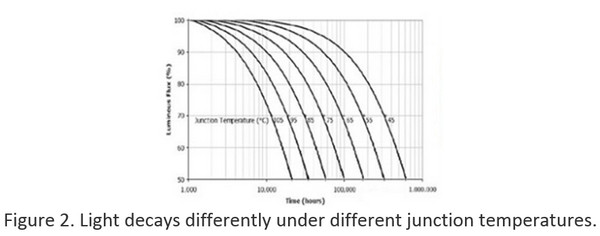

High quality Filament LED lighting products pay extra attention to the thermal management. The high voltage-low current scheme is an ideal combination for controlling the heat. Nevertheless, a reliable LED filament lamp needs to have multiple heat dissipation paths. It is a fact that the junction temperature (Tj) directly correlates to the life expectancy of the LED chips. Figure 2 shows the LED light decay rates under different junction temperatures (Tj). This phenomenon is commonly called the “Droop Effect”. To have a 30,000 hour life expectancy, while maintaining 90% luminous flux, the junction temperature needs to be maintained below 85° C.

|

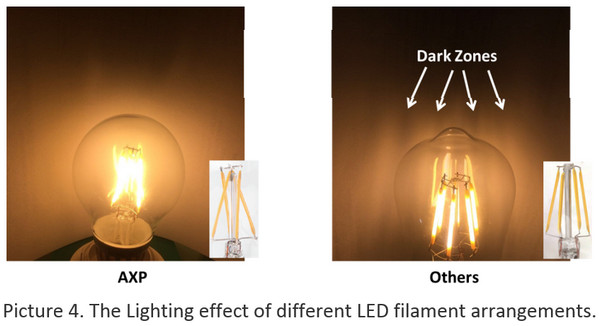

One of the novel approaches to thermal management is to use a special gas mixture inside the glass lamp to facilitate the heat transfer to the glass surface more efficiently than just relying on convection alone. There are other creative ways to dissipate the heat without sacrificing the omnidirectional light. One secret is how you arrange the LED filaments. As we study the commercially available LED filament products on the market today, it is worthy to note that AXP Lighting is the only company receiving both the UL™ and the Energy Star™ certifications for all of its Filament LED™ products. Its patented cross filaments provide a “center of light” without forming any dark zones compared to other “Christmas Tree” type LED Filament designs emerging onto the market. Picture 4 compares the lighting effect between the AXP lamp and other brands.

Filament LED vs. Non-Filament LED Lamp comparison

Filament LED lamps are rapidly gaining market share. To benchmark the big three lamp makers with the AXP Lighting product, the big three are playing catch-up. Table 1 shows the results.

Changing Direction

It is noteworthy that even traditional LED lamp makers like Cree recognizes the advantages of a classic incandescent lamp appearance, which is why they have introduced the 4-Flow product line incorporating an incandescent lamp shape with simple air convection for cooling. This does confirm that lamp manufacturers acknowledge the desire for a classic Edison style lamp which is what consumers really want in their homes. Filament LED lamps appear to have that figured out.

For more information please see: www.axplighting.com

CN

TW

EN

CN

TW

EN