Even without a physical presence, Display Week 2020 still functioned as a major arena for competing technology providers to showcase their offerings. Noteworthy participants that unveiled their latest Micro LED products included LGD, AUO, Tianma, and BOE. In demonstrating their cutting-edge solutions, exhibitors used videos, images, and other media resources to overcome the limitations of the virtual venue.

The lack of physical exhibitions and conferences did not diminish the excitement over Micro LED displays during Display Week 2020. Many prominent developers of this technology had the chance to debut their products and introduce new applications. The variety of Micro LED displays reflects substantial technological breakthroughs and the strategy of strengthening the vertical integration of the supply chain.

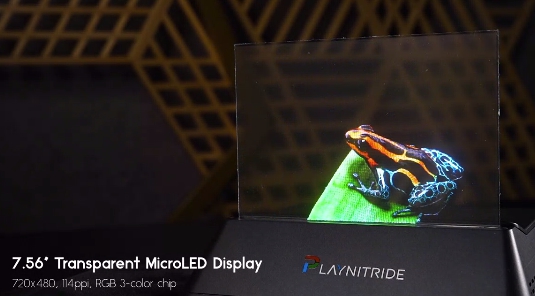

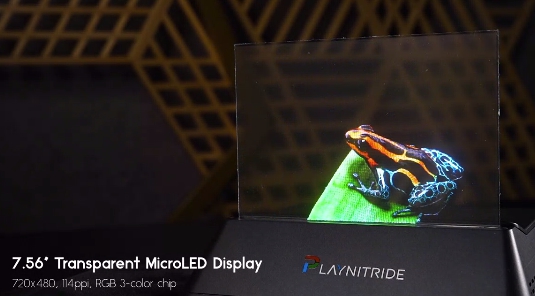

(Image: screenshot of PlayNitride video)

Automotive Displays and Wearable Applications Featuring Micro LED at Display Week 2020

Manufacturers of Micro LED displays have made great strides in product development this year comparing to previous events. A key takeaway from the Micro LED offerings shown at Display Week 2020 is the blossoming applications for flexible displays. Panel suppliers including AUO, RiTdisplay, and Tianma along with Taiwan’s Industrial Technology Research Institute (ITRI) demonstrated their flexible Micro LED solutions for meeting a diverse range of demands such as curved automotive displays and wearable devices. Their products underscore the strong potential of Micro LED in bringing about new and innovative applications.

The Micro LED displays presented by AUO was a center information display that comprises two 9.4-inch flexible Micro LED panels and a 12.1-inch V-shaped Micro LED display for the cockpit. The cockpit display combines the functions for a cluster display and a center information display. The Micro LED panels of both products feature a flexible LTPS driver backplane.

(Image: AUO)

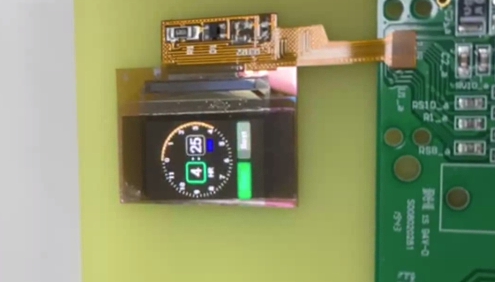

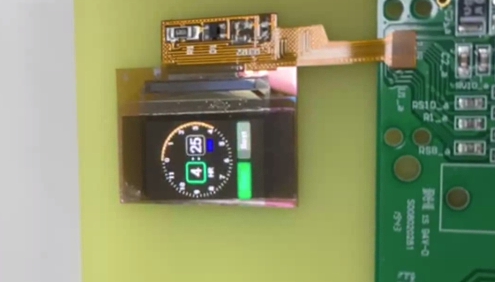

Tianma also showcased Micro LED automotive displays that came in 7.56 and 5.04 inches. The former is a flexible display, while the latter has a resolution of 114 pixels per inch and targets automotive applications. Like AUO, Tianma has adopted LTPS driver backplanes.

(Image: Tianma)

Besides automotive displays, Micro LED display makers also proactively develop products for wearable devices. At Display Week 2020, ITRI brought its latest breakthrough in Micro LED displays for wearables. The product is a flexible Micro LED display module that is capable of producing full color images. Sized 60mm by 30mm, the module uses LED chips smaller than 50 µm and has a pixel pitch of just 250 µm.

(Image: screenshot of ITRI video)

RiTdisplay also focuses on wearable devices and showed off a small-size flexible Micro LED display. Although the specifications of the product were not disclosed, the images of the product suggest that it could be the same 0.94-inch flexible Micro LED display presented by the company at last year’s Touch Taiwan.

(Image: screenshot of RiTdisplay video)

A closer look at the Supply Chain of Micro LED Reveals that Equipment for Mass Transfer and Bonding is the Key Driver of Progress

Taiwan-based PlayNitride is one of the essential technology contributors behind many of the new Micro LED displays at Display Week 2020. In an interview with LEDinside this April, PlayNitride mentioned the 9.4-inch flexible Micro LED panel developed together with AUO was manufactured by mass transferring and bonding of 5.5 million pieces of 15*30 μm LED chip onto a driver backplane.

In dealing with a vast number of LED chips in micron meter size, display manufacturers have to rely on cutting-edge fabrication equipment to complete the challenging process of mass transfer. From an exclusive supply chain sources, LEDinside learned that almost all of the Micro LED displays that were showcased at Display Week 2020 were made using the equipment provided by ASM Pacific Technology (ASMPT).

According to LEDinside’s survey of technologies related to the production of Micro LED displays, ASMPT’s latest equipment system AD300Pro is a solution specifically designed for the mass transferring and bonding of LED chips that are smaller than 50 µm. The tool features a patented bondhead that can attain an accuracy of within 1μm.

The breakthroughs made by ASMPT enable the processing of Micro LED panels as large as 320mm by 410mm. In terms of efficiency, the number of chips per transfer from the wafer to the temporary substrate is 10,000, and the number of chips per bonding from the temporary substrate to the driver backplane is 300,000. All in all, ASMPT’s solution signifies a dramatic improvement in both speed and yield.

It should also be pointed out that ASMPT’s patented technologies do away with the reflow of LED chips as they have been bonded on the driver backplane and evenly laid. The focus on precision and uniformity allows for the accurate generation of RGB colors on the Micro LED display.

With the technological support from ASMPT, display manufacturers can build various types of Micro LED displays by arranging numerous of tiny LED chips as addressable arrays on driver backplanes made from a glass substrate, a PCB, a FPCB, and other.

Challenges lie ahead in Mass Production of Next-gen Displays Based on Mini and Micro LED

Mass transferring and die bonding also pose challenges in the manufacturing processes of displays with Mini LED backlight and self-emissive LED displays. Although Mini LED chips are slightly larger than Micro LED chips, display systems featuring Mini LED backlight still require a much higher chip number compared with conventional display systems. Conventional SMT process is therefore a not a cost-effective method for realizing Mini LED backlight. Looking ahead, the equipment for the mass transferring and bonding of Mini LED chips is expected to be a major focus of investments for participants in the display industry.

LED chip supplier Epistar and LED display maker Leyard Optoelectronic plan to spend around RMB 1 billion (US$ 146.37 million) in a joint venture that will accelerate the R&D of Mini and Micro LED displays. Scheduled to begin operations in the second half of 2020, this entity is reported to have deployed the latest transfer and bonding equipment from ASMPT for the production of displays with Mini LED displays.

A unique advantage of ASMPT’s solution for Mini LED is the ability to automatically correct the XY positioning and rotation of LED chips before they are placed on the driver backplane. A higher bonding accuracy will obviously result in a higher yield rate. ASMPT is the exclusive patent holder of this positioning technology, which is featured in all of its latest line-up of transfer and bonding systems. In the aspect of efficiency, ASMPT’s solution for Mini LED can process large-size panels and achieve a throughput of more than 200,000 chips per hour.

Whether display manufacturers are preparing for the mass production of displays with Mini LED backlight or working on the commercialization of Micro LED displays, they all focus much of their energy on controlling the cost structure and raising the yield rate. Successes in these two areas will help hasten the market releases of their products.

The role of equipment providers is to offer solutions that raise efficiency in different sections of the manufacturing process, from mass transfer to die bonding to inspection and repair. In a sense, they are akin to pit crews of race teams. By responding to the changing needs of display manufacturers, equipment providers build and optimize production lines so that they are always at the peak level with respect to output and operational stability. Thanks to the support from equipment providers, manufacturers of Mini and Micro LED displays have the capacity as well as the confidence to reach the finish line of attaining mass production for the booming market.