Brake pad scorching with TruHeat VCSEL systems for higher quality and more safety // More sustainable processing with VCSEL-based systems // Lower CO2 emissions and a smaller footprint in the factory // Reliable, contactless laser heat treatment

Ulm, May 31, 2023 – TRUMPF Photonic Components, a global leader in VCSEL solutions, offers VCSEL-based heating systems for the scorching of brake pads, to achieve higher quality and, in turn, greater safety with vehicle brake pads. A shorter bedding-in of new pads and possible initial fading is prevented by the scorching process step. “Scorching is a key process step in the manufacturing of brake pads to achieve material properties that lead to high quality and safety,” says Ralph Gudde, Vice President Marketing and Sales at TRUMPF Photonic Components. In the end, the driver safety is increased as the vehicle maintains stable braking performance in different braking conditions. “Not only the process quality is increased by using our TruHeat VCSEL systems, but the processing also becomes more sustainable,” adds Gudde adds. This manufacturing step requires high temperatures. VCSEL-based heating systems offer direct and homogenous infrared laser power, generating high temperatures with reduced energy loss and lower CO2 emissions.

Making brake pad scorching more sustainable

Scorching is the last processing step of brake pad manufacturing. In it, the surface is exposed to high temperatures reaching around 700 degrees Celsius for a short time. In doing so, the effective running-in period is shortened and driving safety with good braking force is ensured, because the scorching brings the surface of the friction material close to the carbonization point to a depth of about one to two millimeters. “Using a laser-based systems leads to lower CO2 emissions and a reduced energy demand, compared to processing with gas ovens or hot plates,” explains Gudde. TruHeat VCSEL systems offer high power density and process the pads without contact, avoiding any contamination or material wear and, thus, increase processing safety. The production line can be shortened as the VCSEL-based heating systems are compact and require a smaller footprint compared to other manufacturing equipment, all the while being easy to integrate.

Digital photographs in print-ready resolution are available to illustrate this press release. They may only be used for editorial purposes. Use is free of charge when credit is given as “Photo: TRUMPF”. Graphic editing – except for cropping the main subject – is prohibited.

Brake pad scorching for driver safety

The scorching of brake pads a mandatory processing step to achieve high quality for more safety for vehicle brakes.

TRUMPF manufacturers in Germany

TRUMPF designs and manufacturers its VCSEL-based systems in Germany.

The TruHeat VCSEL systems are based on single VCSEL smitters.

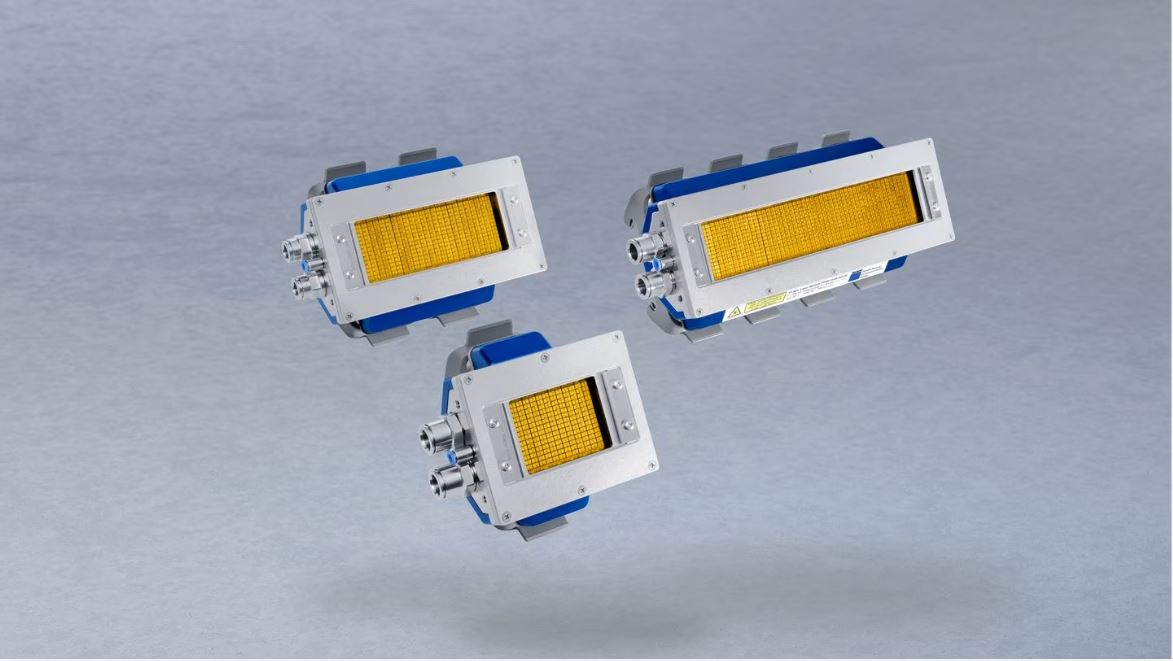

TruHeat VCSEL systems for laser heat treatment

TruHeat VCSEL systems generate homogenous and direct infrared light. not only for brake pad scorching but also, for example, for the softening of high strength steels.

TrendForce 2023 Infrared Sensing Application Market and Branding Strategies

Release: 01 January 2023

Format: PDF

Language: Traditional Chinese / English

Page: 164

|

If you would like to know more details , please contact:

|