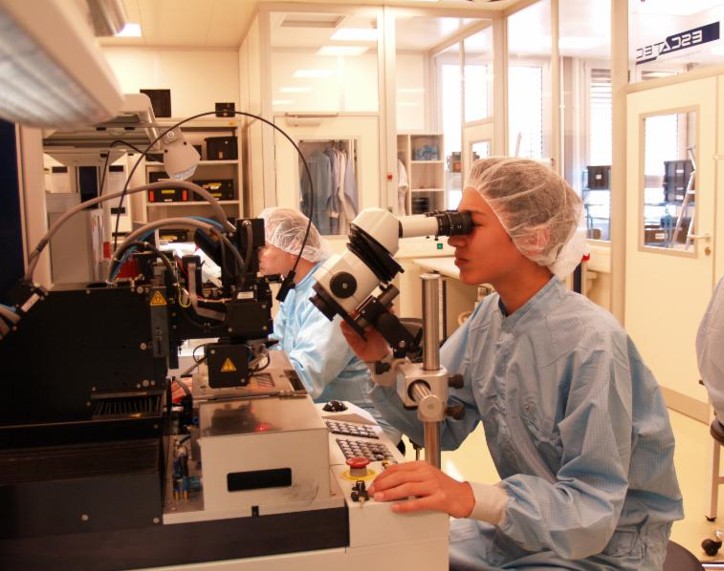

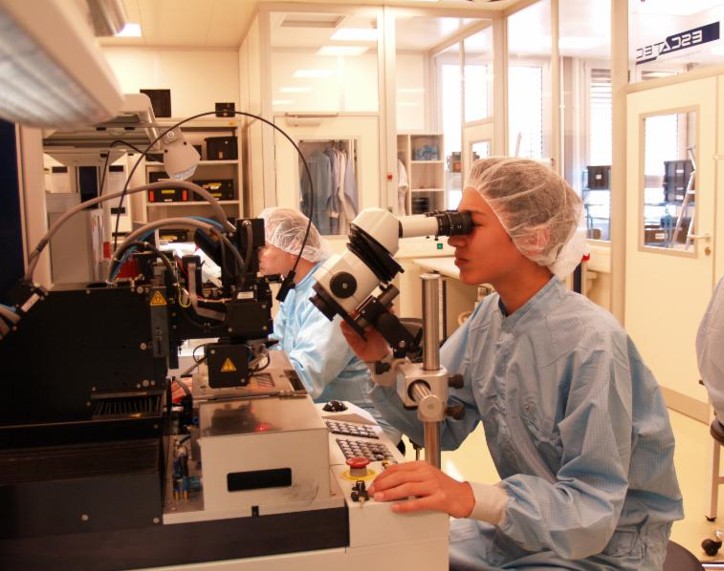

ESCATEC, one of Europe's leading providers of contract and manufacturing services, has nearly doubled the size of its ISO Class 7 cleanroom to meet the increasing need for miniaturized, multi-function components and 'smart materials/systems' with new equipment for material preparation, components creation and assemblies. The expansion includes a 'Future Lab' with advanced state-of-the-art R&D, custom designs, specialised prototyping, and novel process development that will offer leading-edge LED solutions as well as a dedicated workspace next to the cleanroom for 'hands-on' design work with ESCATEC's partners.

|

|

ESCATEC's MOEMS cleanroom. (ESCATEC/LEDinside) |

Wolfgang Plank, ESCATEC's Director of the MOEMS department, explained, "SSL is the main light source in every new microelectronic device, with the market offering many different products accordingly. However, highly-integrated, ultra-miniature, hi-power, specific colour/radiation LEDs for special uses are hard to source because the volumes are just not there compared to standard products. As a specialist in pioneering the use of LEDs, ESCATEC has built up an extensive, reliable sourcing network for base materials, from dies to custom glues and from silicones to special semiconductors to create modules and assemblies. This enables us to offer customers almost limitless possibilities for custom solutions to suit most requirements, volumes, and price points. This doubling of our Class 7 cleanroom will enable us to bring in the latest equipment to provide a world class MOEMS service for an increasing number of customers."

As part of this expansion, ESCATEC is increasing the number of staff in its MOEMS facility so that it is able to meet the growing trend for larger orders. "MOEMS is moving mainstream," concluded Wolfgang Plank, "and ESCATEC is one of the few contract manufacturers to have significantly invested in cleanrooms, equipment and, most importantly, skilled and experienced personnel to be able to fulfil this."

CN

TW

EN

CN

TW

EN