Heat and ultraviolet are used to cure paints such as coatings to protect the surface of car bodies, wooden floors, and plastic containers. Medium-pressure mercury lamps are the primary light source for ultraviolet curing (UV curing).

Originally, heat and drying were mainly used to cure paints, but after the invention of the mercury lamp, the development of materials that can be cured with ultraviolet increased over time, and curing with ultraviolet became and remains widely used.

Compared to curing with heat, UV curing can be used for heat-sensitive materials and can be done in a shorter time. In addition, since mercury lamps have emission spectra ranging from the UV-C to UV-A region1 to the visible light region, ultraviolet of various wavelengths can be used for each application. Because of these characteristics, UV curing technology is now being used for semiconductor manufacturing processes, printing, and paints, making ultraviolet and the medium-pressure mercury lamps that irradiate ultraviolet indispensable to those industries.

Medium-pressure mercury lamps have thus become indispensable to modern society, but as the name implies, they contain mercury, an environmental pollutant. LEDs are expected to be used as an alternative technology. The main hurdle for LED as an alternative is that it is not easy to reproduce the identical spectral characteristics of medium-pressure mercury lamps: LEDs are designed for ultraviolet emission at a specific wavelength while medium-pressure mercury lamps have a broad spectrum and can be used for curing a variety of applications and materials. Therefore, in the RoHS Directive, the manufacture and sale of medium-pressure mercury lamps is allowed under the exemption until at least February 24, 2027 (item 4(f)), because no alternative technology has been established in the field of paint curing using the ultraviolet region.

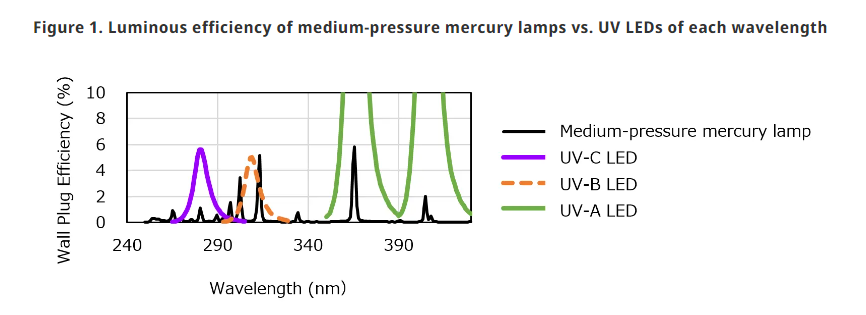

UV LEDs which irradiate ultraviolet are broadly classified into three categories according to their peak wavelength: UV-C LEDs which peak from 265-280nm, UV-B LEDs which peak from 308-315nm, and UV-A LEDs which peak from 365-395nm. UV-A LEDs were developed years ago, and their current performance far exceeds that of medium-pressure mercury lamps in the UV-A range. However, UV LEDs have not been recognized as an alternative technology to medium-pressure mercury lamps due to the lower performance of UV-B and UV-C.

However, this situation has changed dramatically over the past few years. To combat infectious diseases, increased awareness of environmental issues, and stricter regulations, the technological development of UV-C LEDs has dramatically accelerated, and their characteristics have improved year by year. Nichia's 434C LED, which was commercialized last year, now exceeds the luminous efficiency of medium-pressure mercury lamps in the UV-C range.

This post shares the results of an experiment showing that UV-A LED combined with this latest UV-C LED can be used as a sufficient alternative technology to medium-pressure mercury lamps in some paint curing applications.

Every day society uses many plastic containers with labels and images on them. These are often coated and cured to protect the text and images from blurring or fading.

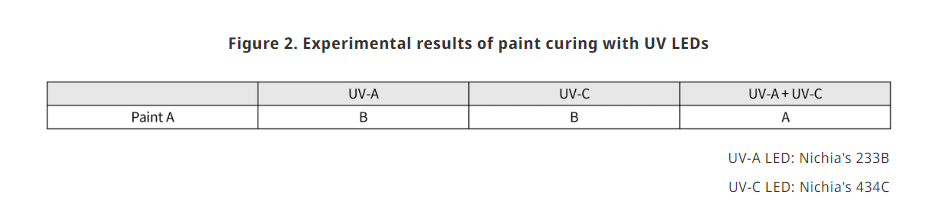

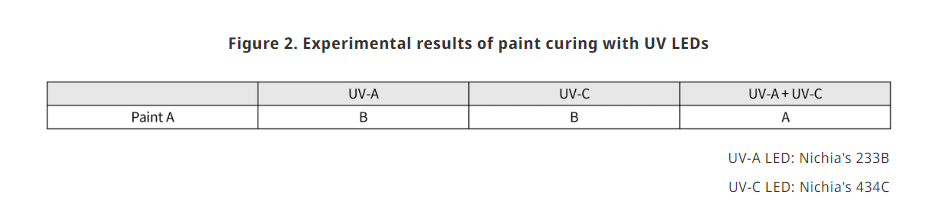

Nichia has conducted an experiment to cure the coating materials on the labels by using UV-A and UV-C LEDs.

As previously thought, the result showed that it was not possible to sufficiently cure the paint with UV-A light alone. Even when using UV-C alone, it was still not possible to sufficiently cure the paint. However, when the UV-A LED was combined with the UV-C LED, it was possible to cure the paint at the same level as with medium-pressure mercury lamps. Although more experiments are necessary to define the curing time, Nichia's experiments so far have shown that the time required is equivalent to or less than that of medium-pressure mercury lamps.

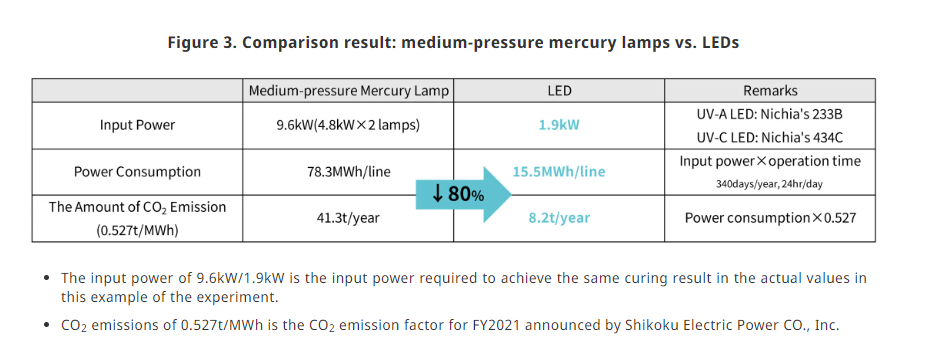

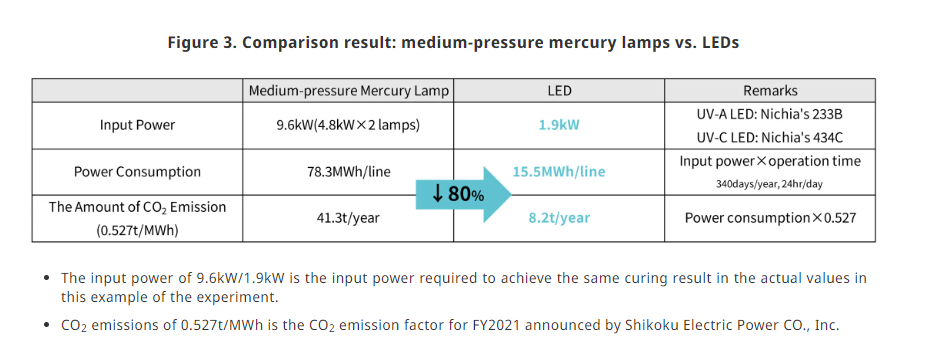

In addition, the power consumption using LEDs was significantly lower than that of mercury lamps. This is because LEDs can specifically irradiate just the target object whereas mercury lamps emit ultraviolet radiation in all directions, generating a lot of wasteful energy. For comparison, the high-pressure mercury lamps used 9.6kW and the LEDs used 1.9kW, an 80% reduction in power.

Based on CO2 emissions of 0.527t/MWh of power consumption, it is calculated that high-pressure mercury lamps emit 41.3t of CO2 per year, while LEDs emit 8.2t, also an 80% reduction.

As mentioned above, medium-pressure mercury lamps, which can emit ultraviolet at various wavelengths, are widely used in the field of paint curing, and since it has taken time to develop alternative technologies with LEDs, the RoHS Directive has also decided to exempt them until at least 2027. With the recent improvements in characteristics, especially that of UV-C LEDs, the situation is changing.

This experiment clearly demonstrated that depending on the application, LEDs can replace medium-pressure mercury lamps as a light source for UV curing, and they contribute to the reduction of power consumption and CO2 emissions.

Nichia strives to further develop UV LED technology and establish a position for UV LEDs as an alternative technology to medium-pressure mercury lamps by accumulating experience in curing various paints with LEDs. This will create a scenario where the extension of the RoHS exemption beyond 2027 will no longer be necessary. In addition, once LEDs become recognized as an alternative technology, the various types of coatings that have been designed and developed over the years to suit medium-pressure mercury lamps should also change to ones that can better demonstrate their characteristics with LEDs. In cooperation with paint manufacturers and users, Nichia will continue to accelerate the trend toward a realization of a mercury-free society and reducing the environmental impact.

TrendForce 2024 Deep UV LED Market Trend and Product Analysis

Release: 31 March, 30 September 2024

Language: Traditional Chinese / English

Format: PDF / EXCEL

Page: 50-60 / Semi-Annual

If you would like to know more details , please contact:

CN

TW

EN

CN

TW

EN