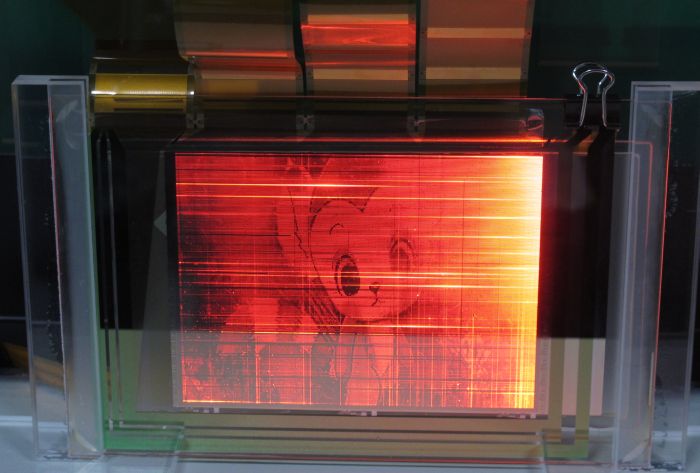

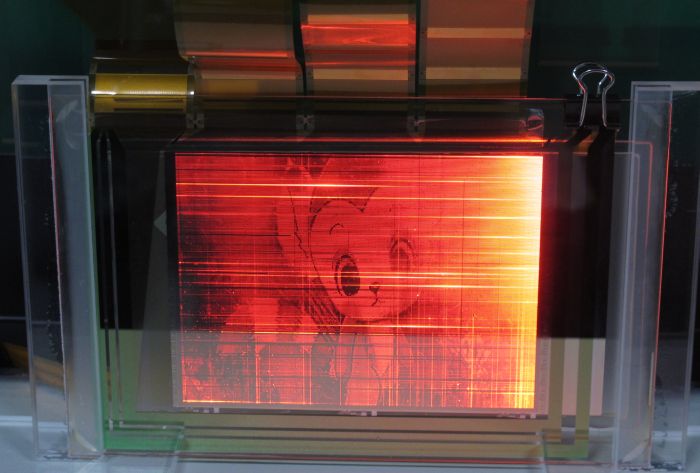

At SID 2013, an academic conference on display technologies (lecture number: P.140L), Japan Broadcasting Corp (NHK) and Nippon Shokubai Co Ltd announced that they thoroughly improved the oxygen and moisture resistances of their OLED device. In addition, they utilized the new technology to demonstrate a display by playing a press preview of Open House 2013 May 28, 2013.

As the development of flexible OLED displays and OLED lighting devices being advanced, their durabilities remain a big problem for commercialization. To solve this problem, the barrier capability of the sealing layer located outside of an OLED device is being strengthened. But it requires special materials and potentially increases costs.

The new technology developed by NHK and Nippon Shokubai proved that it is possible to significantly improve durability just by changing the structure inside an OLED device and its materials.

According to the announcement, the light-emitting area of the previous OLED device produced by NHK and Nippon Shokubai decreases by half in 100 days in the air due to the oxidation of their negative electrodes, while the latest OLED device hardly deteriorates under the same conditions. Therefore, the cost of sealing materials to be located outside of an OLED device can probably be decreased.

The new OLED device has the "inversed OLED (iOLED)" structure, which means the structure between the electrodes of a bottom-emission device is inverted. Specifically, an electron-injection layer, electron-transport layer, light-emitting layer, hole-transport layer and positive electrodes (such as titanium and gold) are formed in this order on a transparent substrate/transparent negative electrodes (ITO).

In a normal bottom-emission OLED devices, the hole-transport layer (such as PEDOT:PSS), light-emitting layer, electron-transport layer and electron-injection layer are formed in this order on a transparent substrate (such as glass)/transparent positive electrodes (such as ITO), and then, negative electrodes (such as aluminum) are formed.