Researchers from Taiwan’s National Tshing Hua University (NTHU) developed a method of adding salt water to quantum dots to make the materials more stable and easier for inkjet printing for optimized Micro LED display manufacture. Their results were published in ACS Applied Materials & Interfaces, titled “Inkjet-Printed Salt-Encapsulated Quantum Dot Film for UV-Based RGB Color-Converted Micro-Light Emitting Diode Displays.”

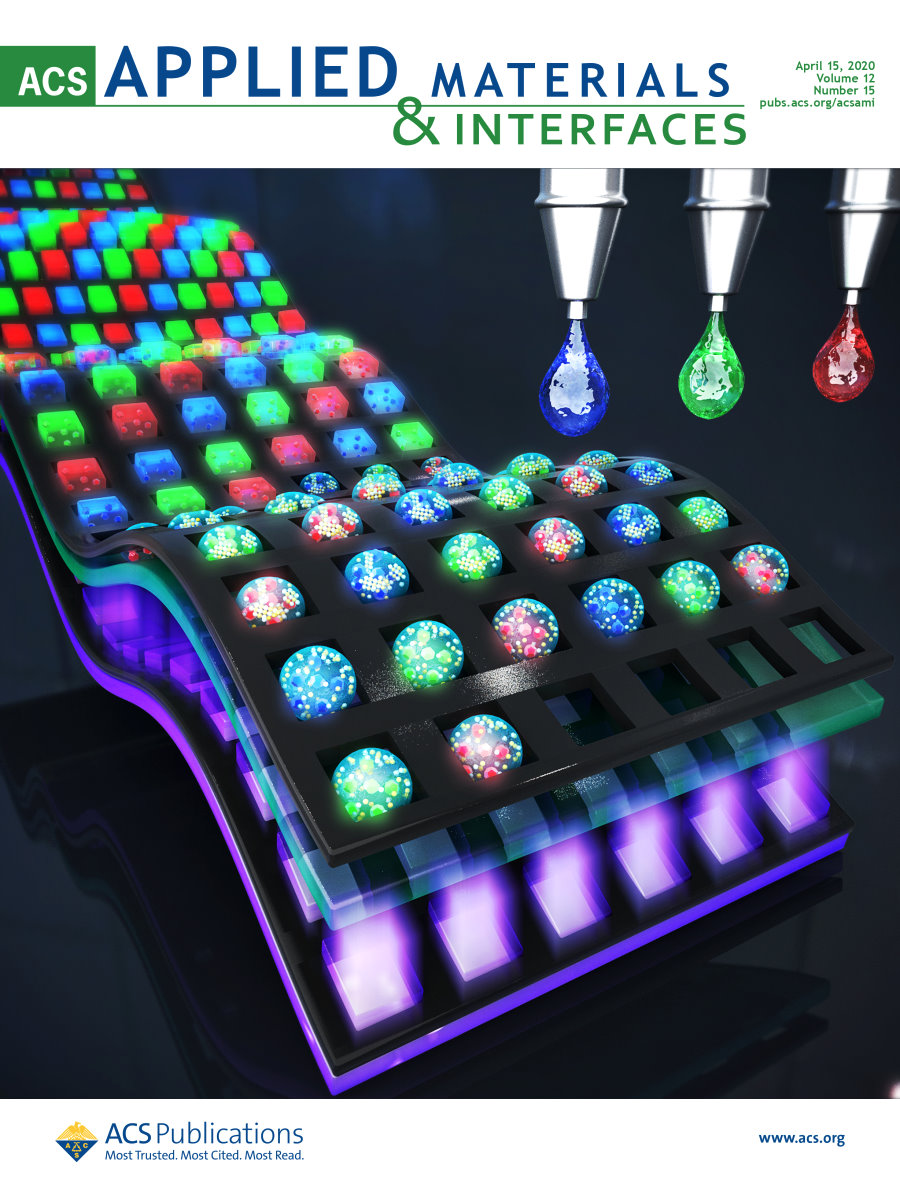

(Image: NTHU)

Full color Micro LED display fabrication is challenging due to poor performance of red Micro LEDs. Many technology developers have thus developed various color conversion approaches to solve the problem for achieving full color Micro LED display cost-effectively. Using quantum dot technology for color conversion is one of the major solutions currently.

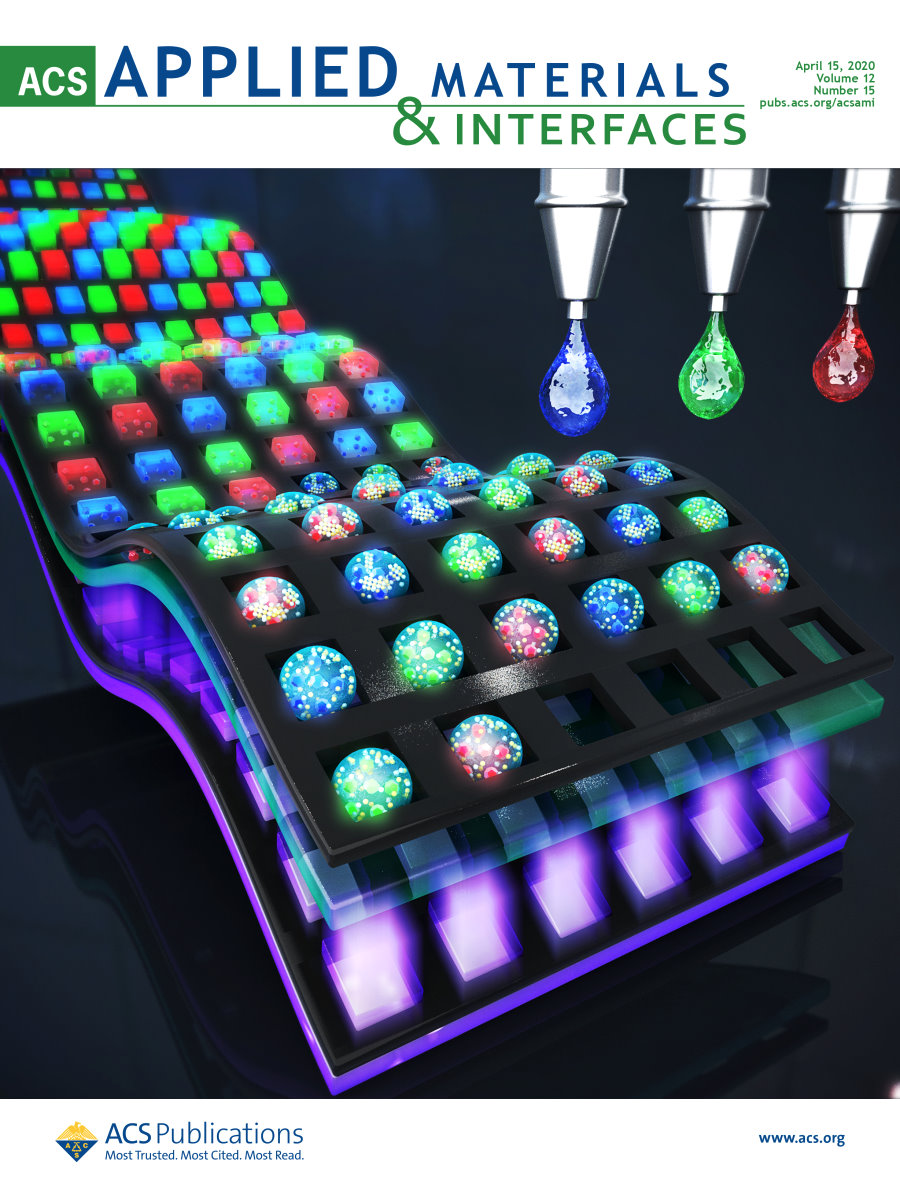

However, since quantum dots are very small, only about three nanometers, their luminosity is easily diminished when affected by water and oxygen. To overcome the difficulty, the research team of NTHU discovered that adding salt water NaCi into a formulated quantum dots ink not only increases materials stability, it also forces the capillary flow inside the liquid drop to crystalize the quantum dots.

Such salt-encapsulated quantum dots can be more easily managed when being inkjet printed on Micro LED displays. Furthermore, the size of each quantum dot can be precisely controlled for accurate color emission.

According to the NTHU researchers, salt-encapsulated quantum dots can achieve 3.74 μm per inkjet printing pixel comparing to 50 μm the conventional quantum dot pixel. The technology enables advanced resolution for Micro LED displays.

(Image:NTHU)