Graz University of Technology (TU Graz) in Austria has develop a new technology by using LED instead of laser as light sources to make metal component by 3D printing. The research project is named Selective LED-based Melting (SLEDM).

SLEDM uses high-power LEDs as light source to melt metal powder for 3D printing manufacturing. The technology is similar to selective laser melting (SLM) and electron beam melting (EBM), in which metal powder is melted by means of a laser or electron beam and built up into a component layer by layer. However, by replacing the light source with LEDs, the project solves the problems of the time-consuming production of large-volume metal components and post-processing.

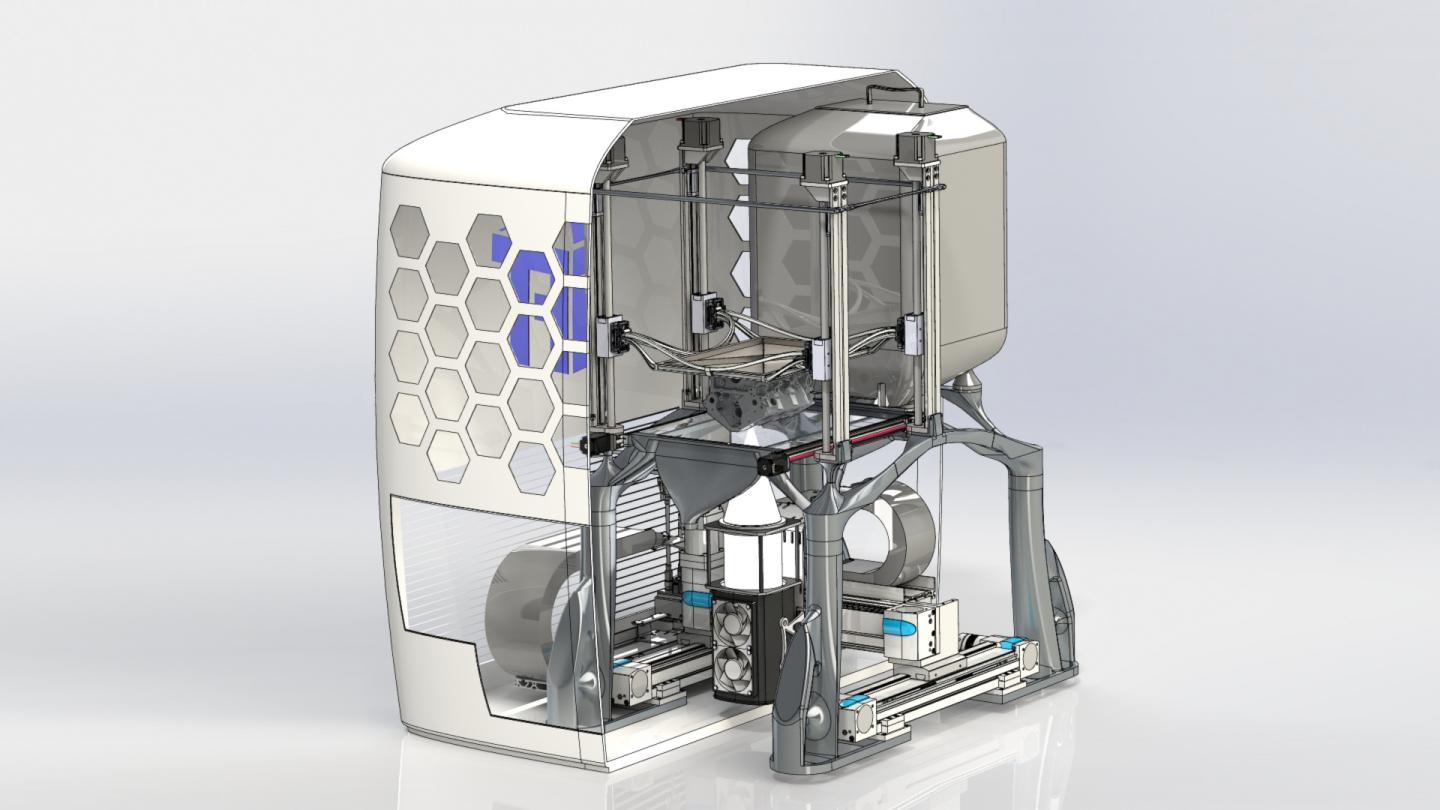

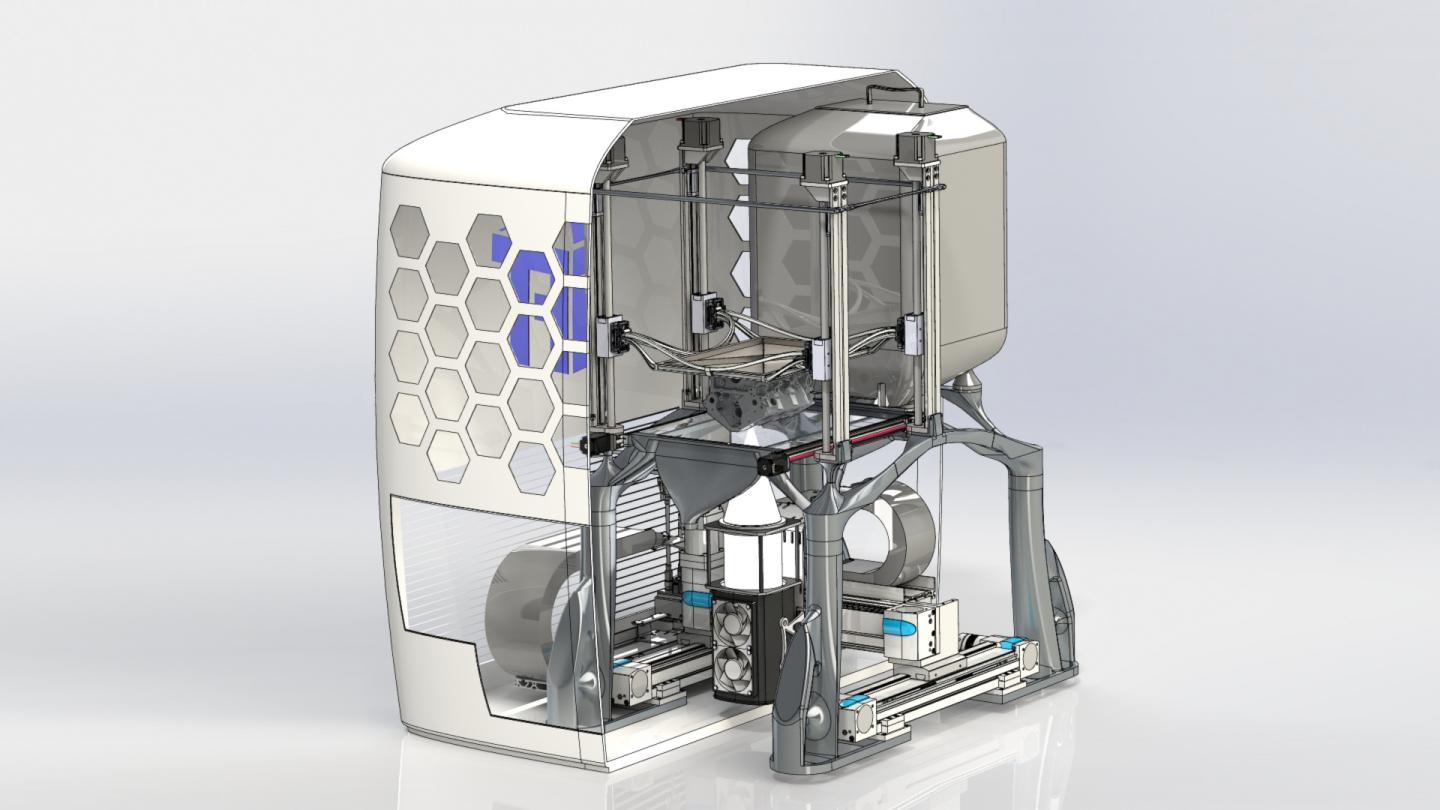

(Image: TU Graz)

According to the research leader Franz Haas of the Institute of Production Engineering at TU Graz, the LEDs used for melting the metal powder were specially adapted by the west Styrian lighting specialist Preworks and equipped with a complex lens system by which the diameter of the LED focus can be easily changed between 0.05 and 20 mm during the melting process. This enables the melting of larger volumes per unit of time without having to dispense with filigree internal structures, thus reducing the production time of components for fuel cell or medical technology, for example, by a factor of 20 on average.

In addition, this technology is combined with a newly designed production plant which adds the component from top to bottom. The component is thus exposed, the required amount of powder is reduced to a minimum and the necessary post-processing can be carried out during the printing process.

Fields of application and further plans

The revolutionary SLEDM process has been demonstrated in the K-Project CAMed of the Medical University of Graz, where the first laboratory for medical 3D printing was opened in October 2019. The process will be used to produce bioresorbable metal implants, such as screws made of magnesium alloys that are used for bone fractures. These implants dissolve in the body after the fracture site has grown together so there will be no need for a second operation for removing the implants. Moreover, the technology will enable the production of such implants taking places directly in the operating theatre since LED light is less dangerous for the operation compared to a powerful laser source.

The other targeted application is to produce sustainable mobility components like bipolar plates for fuel cells or components for battery systems. "We want to make additive manufacturing using SLEDM economically viable for e-mobility and position SLEDM in this field of research at an early stage," said Haas, who will produce a marketable prototype of this 3D metal printer in the next development step: a further innovation in the university environment.