Japanese researchers develop simplified EUV lithography systems to make future chips cheaper to produce

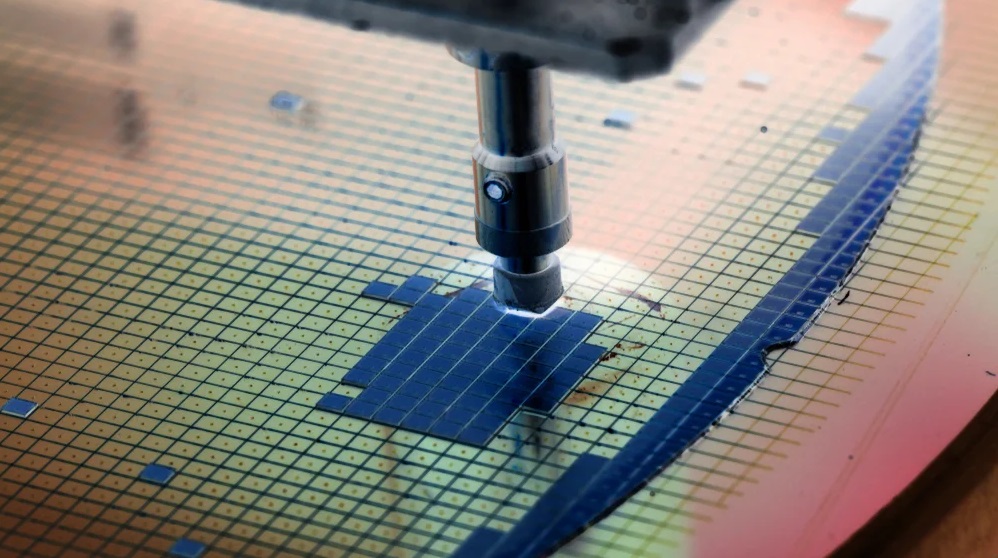

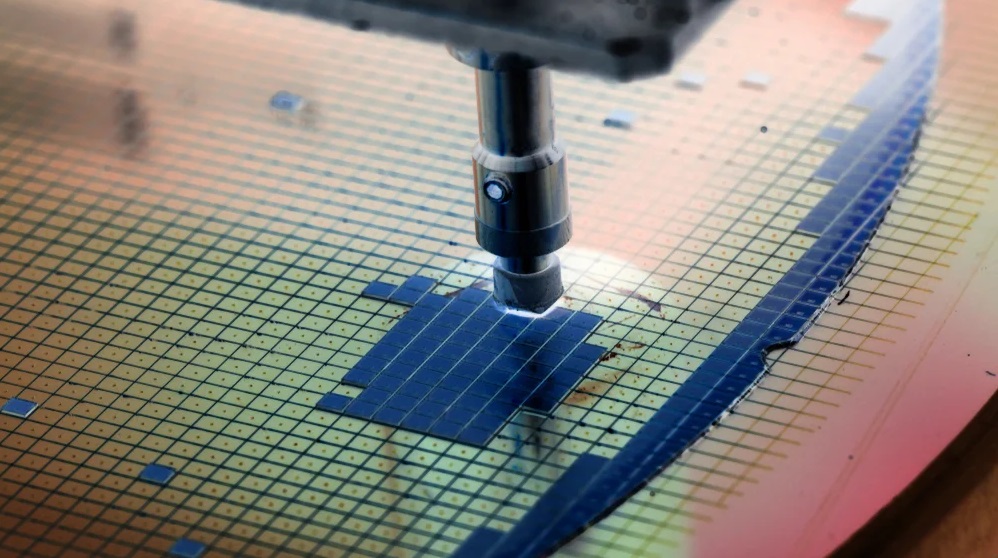

All of today’s most advanced lithography nodes utilise EUV (Extreme UltraViolet) technology. This technology is incredibly expensive, and is a major reason why the cost of high-end chip production has skyrocketed. Now, Professor Tsumoru Shintake of the Okinawa Institute of Science and Technology (OIST) has proposed a new, simplified EUV toolset that could make the production of future EUV chips much cheaper.

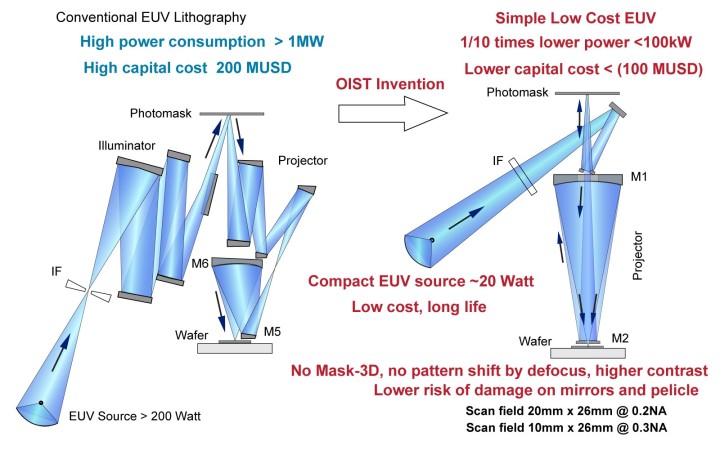

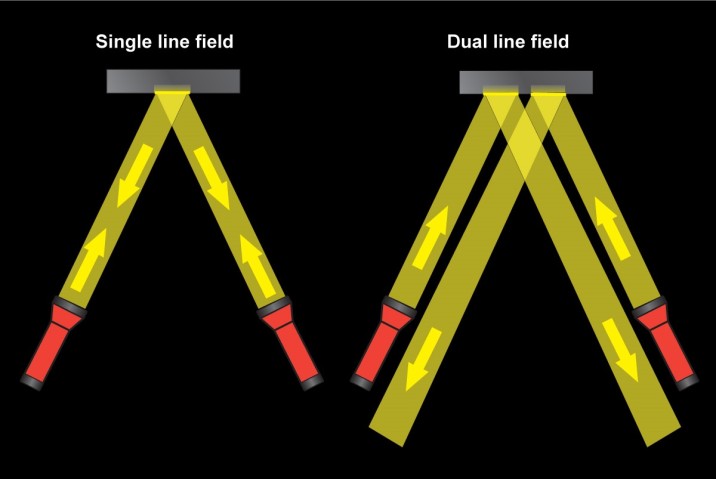

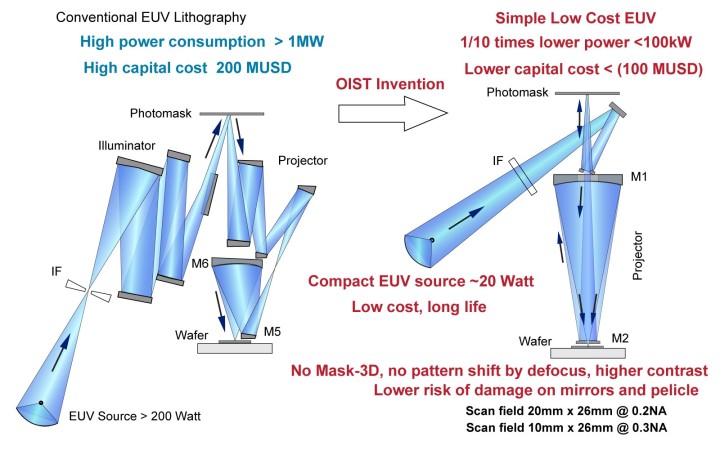

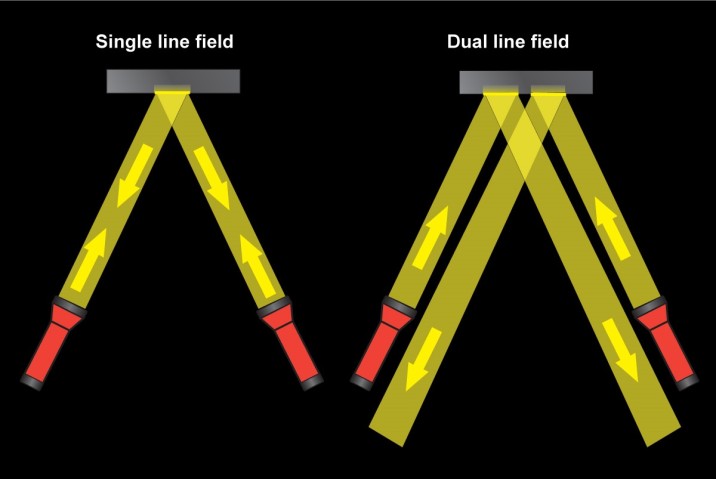

In essence, the OIST has created a new, simplified, EUV technology that works with smaller light sources and uses fewer parts. These changes should enable the creation of smaller, less power-hungry EUV machines that are easier to cool and are less prone to failure.

The ability to use small light sources enables lower running costs. This change both lowers the power and cooling requirements of lithography machines. Furthermore, its use of its novel two-mirror optical projection system has fewer parts, increasing system reliability. This change may also significantly reduce the cost of EUV lithography machines. For context, today’s EUV lithography machines from ASML use six mirrors.

Simplified EUV Tech = Cheaper Chips

With their new lithography tech, the OIST claims that 10% of initial EUV light makes it to silicon wafers. That’s 10x more light than standard EUV setups. This enabled a dramatic reduction in EUV lithography energy requirements. Add on the lower potential machine costs, and future EUV lithography machines could be a lot less expensive.

Lower cost machines can enable the creation of lower cost EUV-based lithography nodes. This can reduce the final cost of EUV-based CPUs, GPUs and other chips. After all, the cost of producing these chips will be lower, and less capital will be required to offset the high technology/machine costs of EUV chip production lines. This could make future processors more affordable, assuming that this technology works as intended.

This EUV technology has the potential to transform the technology industry. It could cause major harm to ASML, the producer to today’s leading EUV lithography machines, and reshape the chipmaking industry. This could have a knock-on effect on major chip foundries like Intel, Samsung, and TSMC, and in turn have a large impact on chip designers like AMD, Qualcomm, Apple, and others.