(Author: Joanne Wu, Associate Director, LEDinsidehttp:// Translator: Judy Lin, Chief Editor, LEDinside)

Many manufacturers and industry leading UV curing and disinfection specialists seeking comprehensive system solutions attended RadTech UV 2016, which took place in Chicago, U.S. from May 16-18, 2016. The exhibition hosts both forums, while showcasing innovative UV products, making it a leading indicator in the UV sector.

|

|

Visitors queuing in front of registration at UV+EB Advanced Materials and Processes Conference Program at RadTech 2016. (All photos courtesy of LEDinside) |

The UV LED market is a highly customized market sector, from the UV LED product chip wavelength, optic module design, picking photoinitiators, and integrating cooling systems. All these require close partnership with Taiwanese curing manufacturers to provide a comprehensive solution. This is one of the methods UV LED manufacturers have implemented to avoid price competitions.

Current UV LED curing design challenges include optic designs, and developing suitable photoinitiators for UV LED products, and how to use suitable UV photoinitiators. Curing with UV LEDs requires using photoinitiators that react to a specific wavelength, and the curing effect varies for different application sectors. For instance, food packing requires photoinitiators for low-migration UV curing, to ensure the food is safe from toxic materials. In most industry applications, curing needs to meet certain intensity, flexibility, or evenness to accelerate the curing process. In wood coating applications, the appearance of the wood has to be natural after curing. In wood curing UV LED applications, many suppliers have entered R&D phase on the market, and provided related solutions.

In UV curing, most manufacturers will use UV curing resin, its three major markets include U.S., Europe and Japan where the technology has developed distinctively. For instance, adhesive resin is much more common in Japan, while UV coating and ink is preferred in U.S., and coating especially for wood coating has a much higher ratio in Europe.

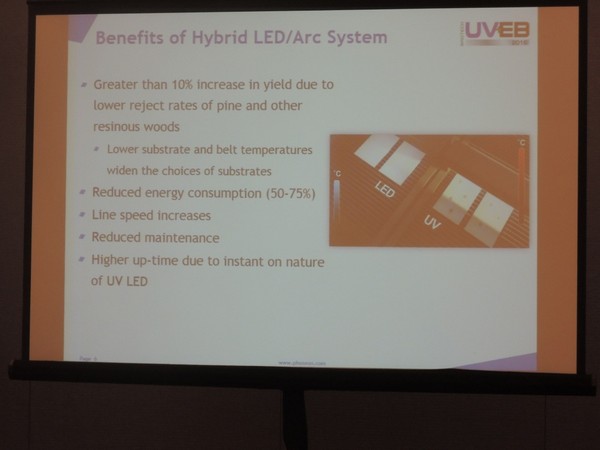

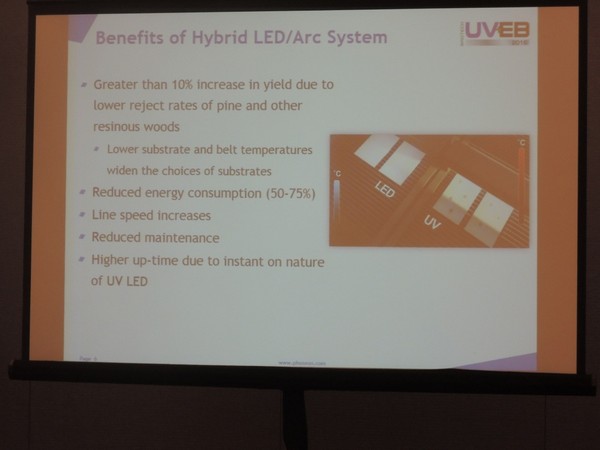

UV LEDs are a suitable curing light source in roller coating applications, said Mike Higgins, Regional Sales Manager, Northeast U.S. and Northeast Canada, Phoseon. In edge curing, UV LED light sources are very convenient. To meet curing effects, system solution providers are using traditional mercury light sources and UV LEDs, due to UV LED price concerns. These solutions combine the advantages of the two light sources, while compensating the two sources flaws. Lastly, UV LED products need to improve irradiance, product efficiency, lifetime, and payback period for it to compete against traditional light sources.

|

|

Advantages of UV curing solutions that use traditional mercury light sources and UV LEDs is listed in a powerpoint presentation. |

List and type of manufacturers that attended the show this year

Manufacturers that showcased their products at the exhibition this year include UV LED package manufacturers, Nichia, Ushio, LG Innotek, SETi, High Power Lighting and others.

|

|

|

|

Booths of UV LED package manufacturers at RadTech 2016. |

UV LED module manufacturers that attended the show this year included Phoseon, Honle, SolidUV/PlayNitride, High Power Lighting, Clearstone Technologies, Heraeus and others.

|

|

|

|

|

Top to bottom: UV LED component manufacturer High Power LIghting, SolidUV and Honle, and Heraleus booths at RadTech 2016. |

Photoinitiator vendors seen at the show include Allnex, Chitec, Eternal, and Miwon.

|

|

|

Top to bottom: Photoinitiator vendor Chitec and CoolWave booths. |

CN

TW

EN

CN

TW

EN