By Anita LaFond, Senior Editorial Manager, Constructive Communication, Inc.

As demand for LED (light emitting diode) luminaries continues to grow, new thermal management technologies are allowing manufacturers to produce LEDs that have higher light output and longer lifespan. LEDs offer many advantages including low energy consumption, long service life (bulbs can last up to 40,000 hours or more), and environmental safety (they contain no mercury). The disadvantages of LEDs, such as higher prices than incandescent or fluorescent lighting, will dissipate as new manufacturing techniques make LEDs less expensive to produce and better able to handle heat fluctuations.

Thermal management is one of the most important aspects of successful LED systems design, according to the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy. LEDs convert only 20- to 30-percent of their electric power into visible light; the remainder is converted to heat that must be conducted from the LED die to the underlying circuit board and heat sinks. Excess heat can reduce LED light output and shorten lifespan. Therefore, managing thermal output to dissipate heat is crucial to maximizing the LED’s performance potential.

A Thermal Substrate Alternative

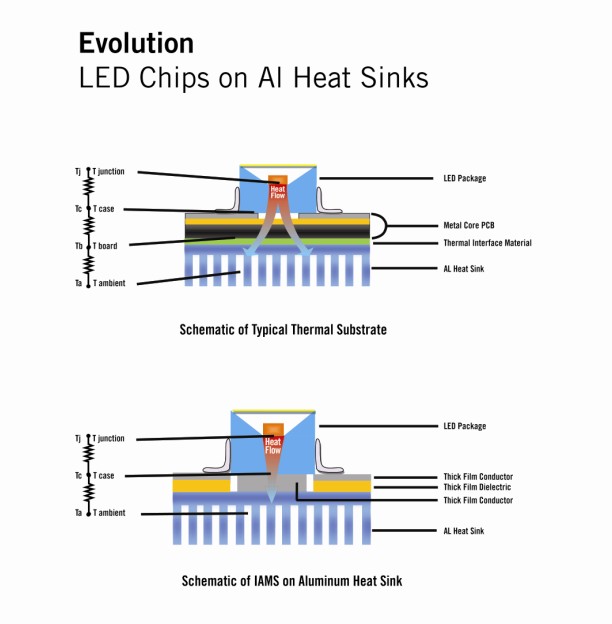

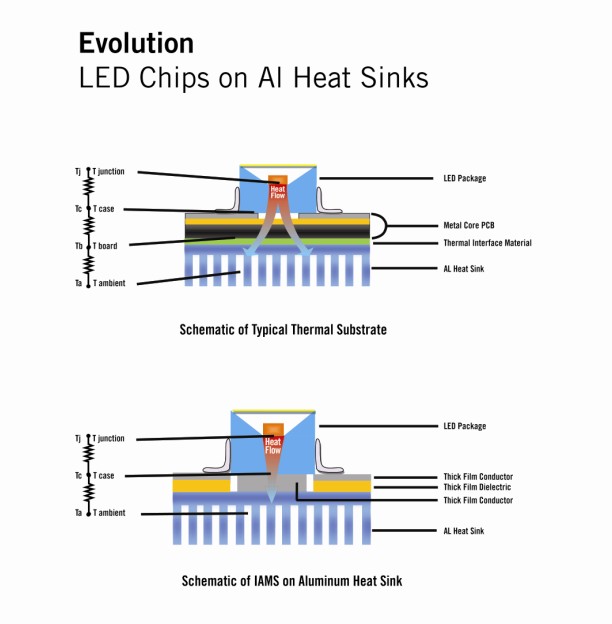

Currently, for high power/high brightness applications, the LED package or module is soldered to a metal-core printed circuit board (MCPCB), thermally enhanced PCB or a ceramic substrate, which is then bonded to a heat sink. Although this configuration is used widely in the LED industry, it does not offer the best method for managing heat conductivity and can be expensive to produce.

MCPCBs and thermally enhanced PCBs offer good thermal performance but have limited design flexibility and can become expensive when high thermal performance is required due to additional costs for machining thermal vias and the high cost of expensive thermally conductive dielectric materials. Ceramic substrates are made from lower thermally conductive, but cheaper ceramics, such as alumina, or higher thermally conductive but very expensive ceramics like aluminum nitride. Overall, ceramic substrates are relatively more expensive than MCPCBs and thermally enhanced PCB substrates.

As an alternative to the substrates discussed above, LED manufacturers are testing the concept of building circuits directly on aluminum substrates, which offer excellent thermal conductivity. Although the LED industry is interested in using aluminum due to its advantages, LED circuits built on aluminum require an insulation layer on the substrate. Now, advances in thick-film technology are allowing the LED industry to reap the benefits of using aluminum substrates.

IAMS, an Insulated Aluminum Material Systems developed by Heraeus Materials Technology, a supplier of products for thermal management applications, is a low-temperature firing (less than 600°C), thick-film insulating system that can be printed and fired on aluminum substrates. The IAMS material set consists of dielectric pastes, conductors, solder masks, and resistors. All the materials are compatible with 3000, 4000, 5000 and 6000 series aluminum substrates.

IAMS Advantages

“IAMS is designed as an insulation system for aluminum substrates,” said Mitsuru Kondo, Global LED Project Manager for the Thick Film Materials Division of Heraeus. “Aluminum cannot handle temperature higher than 660°C, and standard thick-film products are ceramic-based and must be fired at very high temperatures of 800°C to 900°C.

“Because the IAMS pastes can be fired at less than 600°C, the system is compatible with aluminum processing conditions,” Kondo explained. “Also, IAMS’ unique glass system minimizes bowing on aluminum while providing high dielectric breakdown strength and excellent thermal conductivity.”

Most thick-film pastes have a CTE (Coefficient of Thermal Expansion) adjusted for use on high- temperature, low-CTE ceramic substrates. However, if you are using aluminum substrates, which have a very high CTE, and a paste designed for ceramics, the substrate will “bow” due to the differences in CTE. The CTE on IAMS is designed to match the CTE of the aluminum, minimizing any bowing.

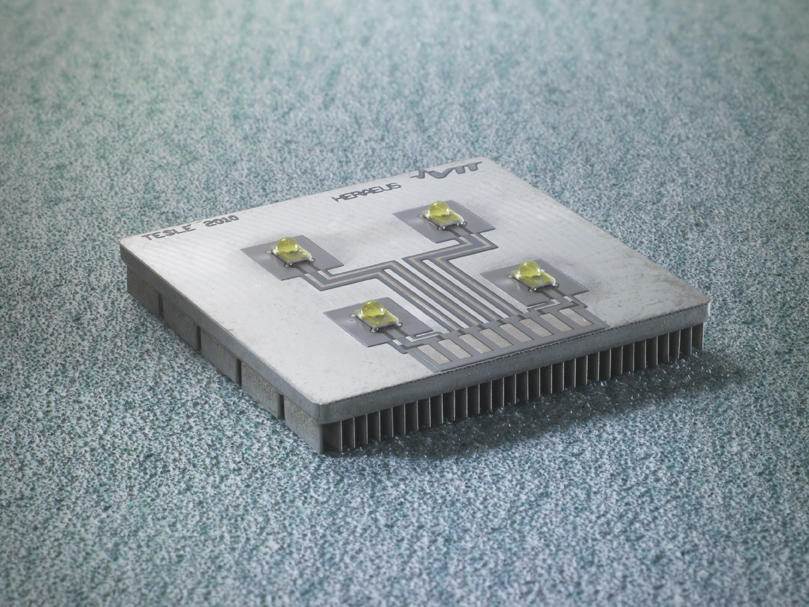

Making modifications to the LED package design is simple with IAMS. “Thick-film technology allows the LED circuit design to be screen printed directly onto the aluminum substrate,” noted Kondo. “The screen pattern can be easily changed to accommodate circuit design changes by simply changing the screen and reprinting.” This flexibility can be advantageous during prototyping and design stages.

In addition, because the printing process used to deposit the IAMS pastes is an additive process with selective deposition capability, costs are low. The insulating pastes are deposited only where the conductive circuit is located and, with the proper design, thermal vias are easily connected directly to the high thermal conductivity aluminum. There is minimal material waste during the circuit manufacturing compared to etched MCPCBs and thermally enhanced PCBs where sheets of copper are chemically etched to create the circuit. With the IAMS system, the conductor paste is deposited only where the circuit needs to be formed.

IAMS technology also allows the customer to use only one insulating paste. While other thick-film technologies require two different types of glass pastes for each insulation layer, only one paste is needed when using IAMS. Finally, all IAMS pastes meet RoHS requirements.

A Proven Technology

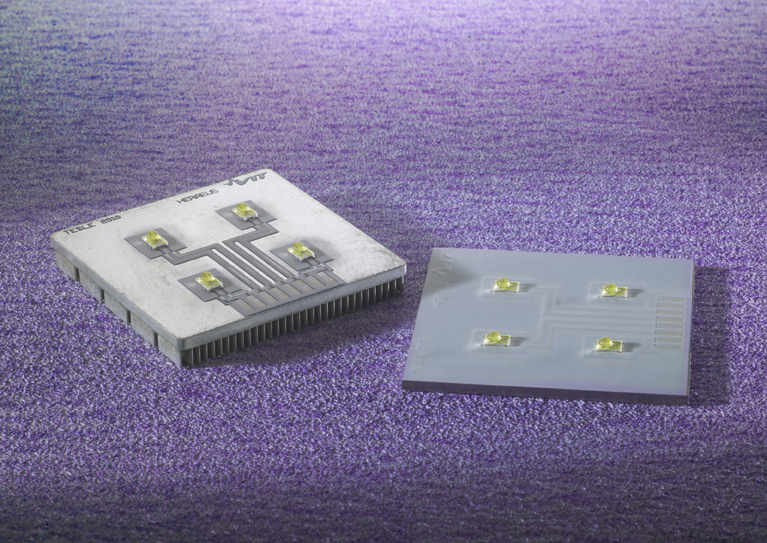

Crucial to the performance of LEDs is effective heat dissipation; keeping the LED’s temperature lower helps to increase brightness and life span. To prove that IAMS could provide the thermal management properties that LED manufacturers required, Heraeus sought independent testing. Heraeus asked the VTT Technical Research Center in Oulu, Finland to perform a comparison study of MCPCBs vs. IAMS.

“We compared the thermal characteristics of LED modules using MCPCBs and IAMS,” said Aila Sitomaniemi, a Research Scientist at VTT. “We tested 10 modules containing high-power LEDs soldered on each board. Each board was placed inside a thermostat chamber that kept the board bottoms at a contact temperature of 25°C to ensure each board received efficient and equal cooling.”

“Test results showed that the LEDs soldered with IAMS paste operated cooler than the LEDs soldered on the commercial MCPCBs,” Sitomaniemi noted. “The average junction temperatures were up to three degrees lower at 350 mA drive current and up to six degrees lower at 700 mA.”

According to Eveliina Juntunen, a Research Scientist at VTT, thermal management is the key feature dominating the performance of LED devices. “When using high-power LEDs, effective heat dissipation is needed to meet the increasing requirements for efficiency, color, reliability, and product lifetime,” said Juntunen.

“Based on the measured results, IAMS decreases the LED junction temperature. The measured thermal resistance between the LED active junction and the board’s bottom was up to 20-percent lower with IAMS than in the MCPCBs,” Juntunen noted. Juntunen said she found these results to be very promising and a significant advantage for optimal LED application.

Heat Sink Printing

The ability to print directly on the heat sink is a future possibility with IAMS. Currently, in most LED assembly operations, LEDs are purchased in package form and an adhesive is used to bond the LED and heat sink to the MCPCB. Every extra layer increases the thermal resistance, which eventually diminishes brightness and life expectancy.

“IAMS technology allows the customer to print the insulation layer directly on the heat sink, eliminating extra thermal resistance from additional thermal substrates (MCPCBs, thermally enhanced PCBs, ceramics, etc),” Kondo commented. “The LED device can be directly connected to the heat sink, providing the best possible method for heat dissipation.”

Lower Heat; Longer Life

Heraeus’ Insulated Aluminum Materials System minimizes thermal resistance by reducing the number of interfaces/layers required in an LED package. This single-part, versatile system allows low-cost design changes and selective deposition for LED manufacturers. The ability to use a less expensive substrate, such as aluminum vs. metal-core printed circuit boards, increases conductivity and lengthens the LED’s life span.

“Keeping the temperature low in the LED package is essential for optimal LED functionality,” concluded Kondo. “By lowering the temperature of an LED by 10 degrees, the life expectancy of the device can be more than doubled and overall costs can be lowered, and that makes LEDs much more attractive to the consumer.”

About Heraeus

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, materials and technologies; sensors; biomaterials, medical products and dental products; quartz glass; and specialty light sources. With product revenues of € 2.6 billion and precious metal trading revenues of € 13.6 billion, as well as more than 12,300 employees in over 110 subsidiaries worldwide, Heraeus holds a leading position in its global markets. For more information, please visit: www.heraeus-thickfilm.com.

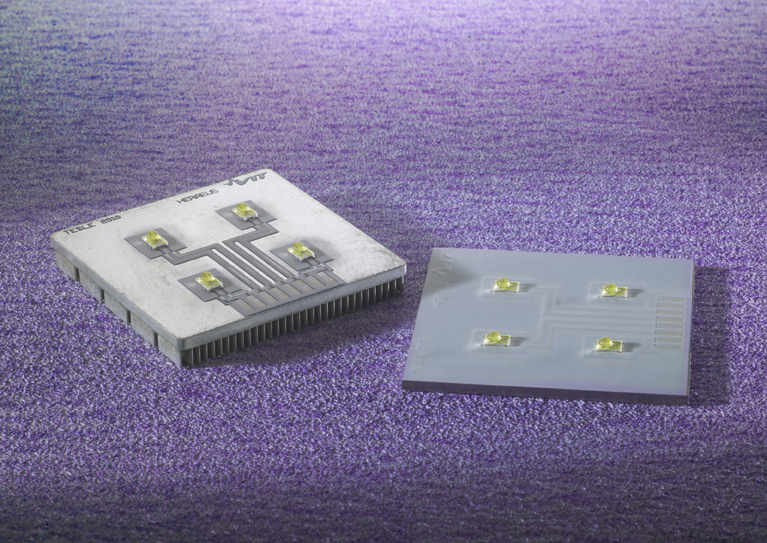

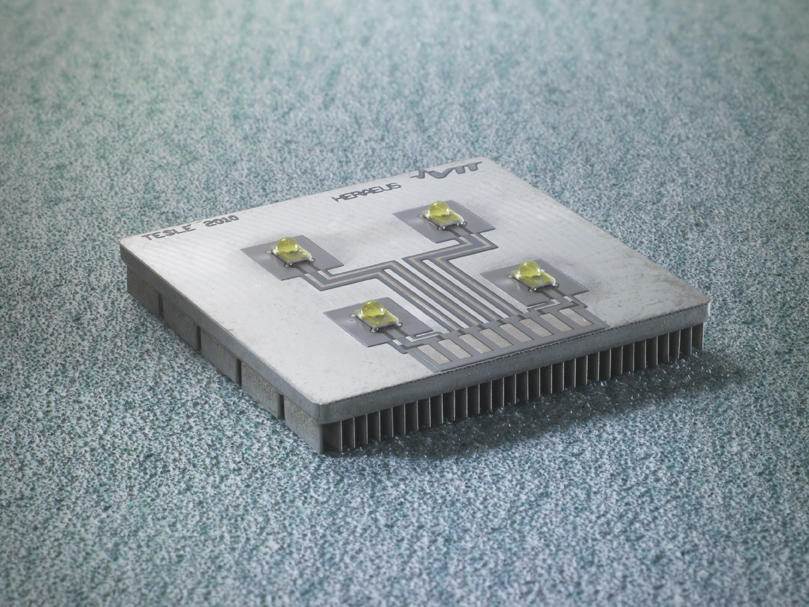

Photo Captions

Heraeus/VTT test circuit using Heraeus IAMS

Magnified Heraeus/VTT test circuit using Heraeus IAMS built on finned heat sink